Neoloy HDPE Geocell Technical Data Best Price HDPE Smooth Geocell Grass Paver

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1900000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

HDPE Geocell Technical Data Best Price HDPE Smooth Geocell Grass Paver

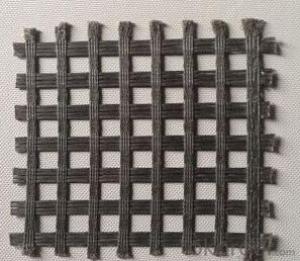

geocell reinforced by high intensity HDPE broadband, after strong welded together a mesh grid structure, it room retractile, transportation can shrink stack up, when using, open and and filling materials, or the concrete was a strong limit and the degree of lateral big just structures. It can be used to as a cushion, reinforcing soft increase the bearing capacity of the foundation, also can be laid in the slope surface slope protection structure form, can also be used to build a block structure, etc.

Product features:

1, material is qualitative light, wear resistance, stable in chemical, resistance to light oxygen aging, acid and alkali resistant, suitable for different soil and geological conditions of the desert, etc

2, higher lateral restrictions and prevent slippery, and preventing deformation, improve the bearing capacity of the roadbed and dispersed loads

3 and the higher the bearing capacity and good dynamic performance, resistance to erosion ability

4, change the geocell reinforced height, welding geometric size is to satisfy different needs of the project

5, retractile, transportation, small size, convenient connection, the construction speed is faster

6, when construction can use local materials, reduce the construction cost, easy to transport with composite

Application:

1, used for solid highway roadbed

2, used for solid railway roadbed

3, used to withstand heavy force of levee, retaining wall

4, used in shallow water river harnessing

5, designed to support the line and the drain

6, used to prevent landslides and heavy force by the hybrid retaining wall

7, for independent wall, wharf, levees, etc

8 on the highway, met in the soft foundation, the geocell reinforced can greatly reduce labor intensity, reduce thickness, roadbed construction speed is quick, good performance, greatly reduce the cost of projects

The product specification: TGLG5 TGLG8 TGLG10 TGLG15 TGLG20 (cm)

Product Description:

High Quality HDPE Geocell for Retaining Wall

Geocell Cellular Confinement System

1.welding distance:330-1000mm

2.height:50-250mm

3.Textured or Smooth surface

4.Color: black,brown,green

we are one of the largest geocell factory in China.

Specification of Best Price HDPE Smooth Geocell Grass Paver

Polymer Density | High Density Polyethylene with density of 0.935 - 0.965 g/cm3 ASTM D 1505 |

Environmental Stress Crack Resistance | > 4000 hours ASTM D 1693 |

Carbon Black Content | Carbon black content 1.5% - 2.0% ASTM D 1603 |

Sheet Thickness | Smooth:1.1mm,1.2mm,textured:1.5mm ,1.7mm ASTM D 5199 |

Cell Details | welding distance:330-1000mm |

Cell Depth | 50-250mm |

Seam Peel Strength | As per US Army Corps of Engineer's Report GL-86-19 Appendix A |

Seam Hang Strength | A 100mm wide seam sample supports a 72.5 kg load for a minimum of 30 days in an ambient room temperature environment. |

Certification | CE ,ISO |

Classification | 1. smooth surface without hole 2. smooth surface with hole 3. textured surface with hole 4. textured surface without hole |

Applying Area of Best Price HDPE Smooth Geocell Grass Paver

1.Be used for firm the roadbed of railroad;

2.Be used for firm highway soft foundation handling;

3.Be used for dike and retaining wall, which can bear load force;

4.Be used to harness the shoal water runway;

5.As pipeline and the sewer's propping up structure;

6.Be used for mixed type retaining wall that prevent the slope from falling down and bear load force;

7.Be used for independent wall, dock and breakwater;

8.Be used to harness the desert, beach and riverbed ,river bank

HDPE Geocell Technical Data Best Price HDPE Smooth Geocell Grass Paver

Height (mm) | Welding distance (mm) | Sheet thickness(mm) | Tensile yield strength of the cell≥(MPa) | Seam peel strength≥(N) | ||

smooth | textured | |||||

GS50-400 | 50 | 400 | 1-1.1 | 1.4-1.5 | 20 | 500 |

GS100-400 | 100 | 400 | 1-1.1 | 1.4-1.5 | 20 | 1000 |

GS150-400 | 150 | 400 | 1-1.1 | 1.4-1.5 | 20 | 1500 |

GS200-400 | 200 | 400 | 1-1.1 | 1.4-1.5 | 20 | 2000 |

GS75-330 | 75 | 400 | 1-1.1 | 1.4-1.5 | 20 | 750 |

GS100-330 | 100 | 400 | 1-1.1 | 1.4-1.5 | 20 | 1000 |

GS150-330 | 150 | 400 | 1-1.1 | 1.4-1.5 | 20 | 1500 |

GS200-330 | 200 | 400 | 1-1.1 | 1.4-1.5 | 20 | 2000 |

High Strength HDPE Geocell Technical Data

NO. | Test Item | Unit | Index |

1 | Band tensile strength | MPa | ≥200 |

2 | Tensile strength at connecting | N/cm | ≥150 |

3 | Break elongation | % | ≤15 |

- Q: Can geogrids be used in reinforcement of geosynthetic clay liners?

- Yes, geogrids can be used in the reinforcement of geosynthetic clay liners (GCLs). Geogrids are often used as a reinforcement material to enhance the tensile strength and stability of the GCLs, thereby improving their performance in applications such as slope stabilization, landfill liners, and erosion control. The geogrids are typically placed between layers of GCLs to provide additional support and prevent potential failure modes, such as shear sliding or lateral spreading.

- Q: How do geogrids improve the performance of mechanically stabilized slopes in sandy soils?

- Geogrids improve the performance of mechanically stabilized slopes in sandy soils by providing additional reinforcement and stability. They are typically made of high-strength polymer materials and are placed within the soil to distribute loads and increase the overall strength of the slope. The geogrids act as a barrier, preventing the movement of soil particles and reducing the risk of erosion. This reinforcement helps to maintain the integrity of the slope, preventing it from sliding or collapsing. Additionally, geogrids can enhance the overall lifespan of the slope by reducing the stress on the soil and mitigating the effects of settlement.

- Q: What are the types of Geogrid

- Glass fiber geogrid, 1595341 polyester fiber geogrid, glass fiber, polyester composite geotextile, steel plastic composite geogrid, PP grid, one-way two-way stretching plastic geogrid,

- Q: Can geogrids be used in temporary access roads?

- Yes, geogrids can be used in temporary access roads. Geogrids are commonly used in the construction industry to reinforce soil and provide stability. They can be an effective solution for creating temporary access roads, as they help distribute the load and improve the strength of the road surface.

- Q: What is the effect of junction strength on geogrid performance?

- The junction strength of a geogrid directly impacts its performance. A higher junction strength enhances the overall stability and load-bearing capacity of the geogrid, allowing it to effectively restrain soil movement and distribute loads. It also improves the geogrid's resistance to deformation, puncture, and tearing. In summary, a strong junction enhances the geogrid's effectiveness and durability in various geotechnical applications.

- Q: Geogrid test items: what is the point of the joint point?

- The conventional test items of geogrid are tensile strength, elongation, and welding point peeling force.So it is not feasible for you to put the waterproof material on the geogrid.

- Q: Can geogrids be used in retaining walls for waterfront parks?

- Yes, geogrids can be used in retaining walls for waterfront parks. Geogrids are commonly used in retaining wall construction as they provide reinforcement and stability to the soil. In the case of waterfront parks, where the retaining walls are exposed to water and potential erosion, geogrids can help prevent soil movement, maintain the integrity of the wall, and enhance its overall durability.

- Q: What is the recommended installation method for geogrids?

- The recommended installation method for geogrids is to first prepare the subgrade by removing any vegetation or loose soil, and then compact the subgrade to achieve a stable base. The geogrid should be unrolled and placed on top of the prepared subgrade, ensuring it is stretched and anchored securely at the edges. Overlapping the geogrid panels by the manufacturer's recommended amount and using connector devices may be necessary. Finally, the geogrid should be covered with an appropriate fill material and compacted in layers to ensure proper integration and load distribution.

- Q: How do geogrids improve the performance of geotextile tubes?

- Geogrids improve the performance of geotextile tubes by providing additional structural support, enhancing stability, and increasing tensile strength. They help to prevent stretching and deformation of the geotextile material, thereby maintaining the shape and integrity of the tubes. This reinforcement helps to withstand the forces exerted by water, soil, and other external factors, making geotextile tubes more durable and effective in applications such as erosion control, shoreline protection, and environmental containment.

- Q: What are the properties and characteristics of geogrids?

- Geogrids are synthetic materials, typically made from polymer materials such as polyethylene or polypropylene, that are used in civil engineering and construction projects. These materials possess several important properties and characteristics. Firstly, geogrids have high tensile strength, which allows them to effectively distribute loads and provide structural reinforcement to the soil. They also have excellent resistance to chemical and biological degradation, making them suitable for long-term applications in various environmental conditions. Geogrids are lightweight, flexible, and easy to handle, making installation and transportation more convenient. Additionally, these materials exhibit low elongation and creep characteristics, ensuring long-term stability and performance. Overall, geogrids offer superior soil stabilization, erosion control, and reinforcement properties, making them valuable in a wide range of geotechnical and construction projects.

Send your message to us

Neoloy HDPE Geocell Technical Data Best Price HDPE Smooth Geocell Grass Paver

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1900000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords