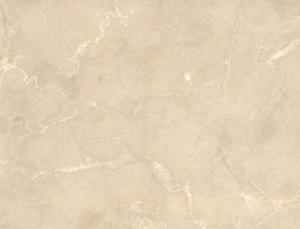

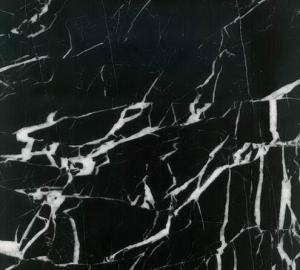

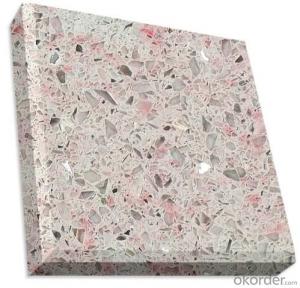

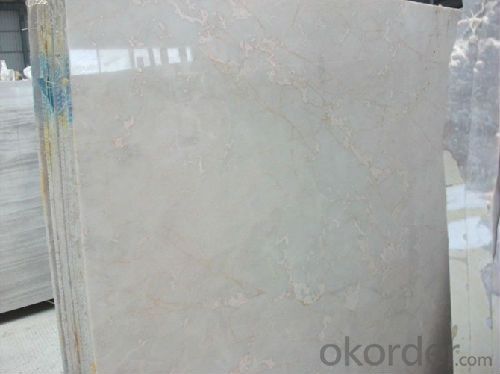

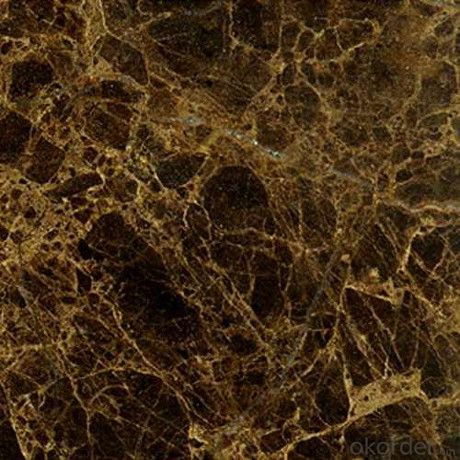

Natural Marble Vein Style in Different Size

- Loading Port:

- Fuzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

1. Description

| 1 | Material | Marble |

| 2 | Size | 300x300x10mm 457x457x20mm 600x600x20mm 2800x1600x25mm, or as customer require |

| 3 | thickness | 25px, 50px, 75px, 100px or other thickness your requirement |

| 4 | Color | grey, red, white, yellow, black, coffee, beige, green, ect |

| 5 | Finished | honed, polished, sandblasted bush hammered, rough picked, Mushroom, Axe-cut, etc. |

| 6 | Application: | Skirting,Tread & Riser stairs, Bollard, Column,Curbstone, Paving,Flooring,etc Window sill, Kitchen top, counter top, Vanity top, Work top,etc Statue, Tomb and Monument,etc Wall cladding Cube,Border,etc |

| 7 | Payment terms | T/T 30%deposit and 70%balance(pay against B/L copy) or negotiation |

| 8 | Packaging | Thick tiles are packed directly in wooden crates, with safe support to protect the surface& edges, then in strong wooden crates. |

| 9 | Quality | All stone edges without breaking angle, no crack. |

| 10 | Min. Order | One 20GP container,Small order is acceptable, we can ship it by LCL shipping to your destination |

| 11 | Delivery time | According to your purchase quantity |

| 12 | Place of original | Fujian,china |

2. Advantages

Good price and fast delivery.

3. Pictures

4. FAQ

How about delivery time?

40~50 days.

How about MOQ?

100sq.mt per pattern.

- Q: How to clean the black marks left by marble

- On the marble with fruit juice, coffee, water, beverages and nicotine and other stains, with a few drops of vinegar powder can be wiped off the water, wipe clean and then rinse with water. To remove the ash on the marble, scrub with soap and water. Gasoline can wash away the grease on the marble. When stained with ink and other stains on the marble, you can use 20 pieces of water in a hydrogen peroxide water add a few drops of ammonia, wipe with a soft cloth dipped in this solution, and then wipe dry with a soft cloth.

- Q: What is the difference between terrazzo floor and marble and floor tile?

- Ceramic tiles are purely man-made, is a variety of clay after a variety of process firing, the maximum not more than 1.2 m X1.2 m;

- Q: What is the back stone

- Stone back muscle: because in the stone cutting into sheet, the thickness is very thin, very easy to break, in order to increase the stability to avoid damage or rupture in operation while adding reinforcement in the stone back slot, called the stone back muscle, the general use of steel 0.5 or 0.8 implants.

- Q: Bathroom marble wall with a paste technology

- (1) process: primary processing, leveling line hanging on horizontal and vertical control lines * * inspection * color number pre woven patterns, mosaic stone installation * * repair gap * * clean polishing wax.(2) according to the division of the slate in the construction drawing, the horizontal and vertical dividing line of the stone plate is played on the base layer to carry out the pre arrangement of the stone slab.(3) according to the exact distance between the elastic line and the stone slab, at the plate joint, hang out the control line.(4) the control line is made of nylon wire or steel wire, in which the horizontal control line is connected with the safety.(5) a vertical control line is hung at both ends of the wall and in the middle part of each of the 4 channels.(6) slab installation:

- Q: How to identify the true and false marble?

- Each piece of natural marble has a unique natural patterns and colors, high-quality marble furniture will choose a block of stone raw materials for different parts of the material ratio. The main parts will have a large area of natural lines, and leftover materials will be used in the back of the chair, stigma and other parts to do embellishment. But in the inferior furniture materials selected scrap, lack of surface changes.The marble furniture used in many varieties, some species need to stain, and green jade, jade stone and red stone is pure natural. Some inferior products will be low-grade white marble dyed green jade, and the color of these products are mostly natural emerald green.Artificial marble is made of natural marble or granite gravel as filler, cement, gypsum and unsaturated polyester resin as adhesive, after mixing, grinding and polishing. The transparency of artificial marble is not good without natural texture, and no luster.Identification of man-made and natural marble is simpler: a few drops of dilute hydrochloric acid, natural marble severe foaming, artificial marble is sparkling weak even without bubbles. If you have the kind of material you can try it yourself.

- Q: What kind of marble

- Select the pattern color: marble plate color spot LAN, color diversity, patterns are not the same, this is the marble plate of the precious charm. The tone is basically the same, the color difference is small, the pattern is beautiful is the specific performance of good varieties, otherwise it will seriously affect the decorative effect.

- Q: How to repair the marble furniture

- 1 clean the marble furniture with clean cloth, remove any dust and impurities.2 dry the soft cloth and then wipe it with it.3 dry the furniture with a dry towel to avoid the stripes.4 use marble sealant to prevent possible staining.5 apply a layer of wax on the surface, wipe off the wax as the sealant is completely dry.

- Q: Must be used to clean the floor on the floor

- 1, the surface of ordinary dust can choose detergent, soap, washing powder, etc.. 2, the production of wax layer, can be used to remove the king decontamination. 3, the surface of the cement residue, filler and other dirt, can be used to remove dirty king. 4, paint, paint and other pollutants using chemical solvent dissolution, such as days of water, etc.. 5, black metal scratches, welding, etc. can be used to remove dirty king.

- Q: Natural marble radiation big?

- Marble is formed by the influence of external factors such as high temperature and high pressure. Because of the low levels of radioactivity in the composition of calcite and dolomite, the radioactivity of the marble, which is made up of very low radioactive limestone.There are two main aspects of radioactive damage in natural stone: in vivo and in vitro.

- Q: Marble decoration with radiation in the end there?

- Natural marble and artificial stone, each has advantages and disadvantages, see what you do. If the shop floor or marble, artificial stone is not good, because if you do wear. Table or window, because some good artificial stone, artificial stone can be made into one body, no seams, marble is very difficult to make such the effect of marble. Of course there is a little radiation, but now the nature of the radiation radiation everywhere, do not stare at the marble seriously. The artificial stone has no radiation, but the raw materials of artificial stone include some polymer compound, who can say these things without harm? Health hazards of formaldehyde / decoration after the benzene on people is the biggest, and all these things are not human compounds made out of their own? So I think, what is the best natural

Send your message to us

Natural Marble Vein Style in Different Size

- Loading Port:

- Fuzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches