Solar Energy - Best Quality Flexible Solar Cells with CE, RoHS, ICE Certification

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 500 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

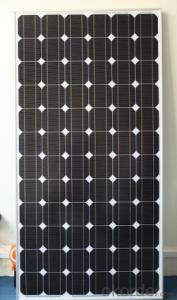

| Model Number: | ANM250M-96 | ||||

| Material: | Monocrystalline Silicon | Size: | 1575*1082*50 | Number of Cells: | 250 |

| Max. Power: | 250 | Certificate: | CE, ROHS, ICE | Warranty: | 5 years |

| keywords: | flexible solar cell | Short circuit current(Isc): | 5.95 | Open circuit voltage(Voc): | 58.40 |

| Current at max power(Imp): | 5.28 | Voltage at max power(Vmp): | 47.33 | Max. Power (Pm): | 250 |

| Operate Temp. scope: | -40~85 | Impact Resistance: | AC2000V; DC3000V |

Packaging & Delivery

| Packaging Detail: | standard export package suitable for long seavoyage and tough handling |

| Delivery Detail: | 10-25 days depending on order quantity |

Specifications

flexible solar cell

1.Monocrystalline

2.Solar Panel Factory

3.CE, ROHS, IEC

4. 5yrs warranty

Types of Solar Cell

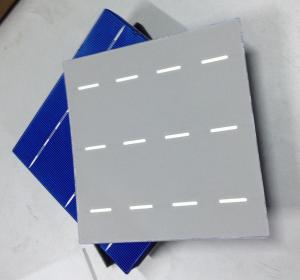

Current solar cells are classified into several types according to the material, structure and the manufacturing method used. Wherein the multi-crystalline silicon solar cell refers to the silicon semiconductor substrate is a monocrystalline silicon solar cells and a raw material polycrystalline silicon solar cells; in addition to amorphous silicon-based solar cells, such batteries with the liquid crystal panel prepared by the same film is based, it is deposited on a silicon substrate instead of a glass substrate made of amorphous silicon.

Monocrystalline silicon solar cells are formed on a monocrystalline silicon substrate, but also the conversion efficiency up to 20% of the products, with excellent performance and reliability characteristics. However, as the price of raw materials expensive silicon substrate, the higher cost of electricity per watt. Although polycrystalline silicon solar cell conversion efficiency is lower than that of silicon solar cells, with the advantage of cheap cost.

Most substrate monocrystalline and polycrystalline silicon solar cell used is from the slowly cooled liquefied silicon after heating the crystalline silicon block (ingot) cut out of the sheet manufacturing. Forming a polycrystalline silicon solar cell uses polycrystalline silicon ingots; forming a single crystal silicon solar cell uses single crystal silicon ingot. Compared with polysilicon ingot, single crystal silicon ingot production efficiency is lower, therefore more it is more expensive.

The more cutting thin silicon substrate, the silicon ingot obtained by the same base plate number, the more, the lower the cost. However, there are also disadvantages sheet cut easily broken during the manufacturing process. So how global materials manufacturers around the sheet during cutting and increase yield, reduce cost in a fierce competition.

Using a thin film of amorphous silicon solar cell production method is different significantly reduce the amount of silicon used, and vacuum evaporation using a manufacturing process suitable for mass production, as compared with the crystalline type can significantly reduce costs, but the amorphous silicon solar cell lower conversion efficiency is only about 10%. Such batteries silicon feedstock prices of the period of concern, but with the tight silicon market weaker than expected growth in its share.

- Q: Can I trust the suppliers for film solar that I found on alibaba ?

- Well, it really depends on what kind of suppliers you are dealing with, because as a matter of fact, some of the suppliers on alibaba are very tricky!

- Q: What is the role of anti-islanding devices in solar cell systems?

- The role of anti-islanding devices in solar cell systems is to ensure the safety of utility workers by preventing the solar system from continuing to generate and supply electricity to the grid during a power outage. These devices detect when the grid connection is lost and immediately disconnect the solar system, preventing any potential harm or damage that could occur if electricity was still being fed into the grid.

- Q: What is the role of tracking systems in maximizing solar cell efficiency?

- Tracking systems play a crucial role in maximizing solar cell efficiency by continuously adjusting the position of solar panels to optimize their exposure to sunlight. This ensures that the panels are always facing the sun at the optimal angle, resulting in increased energy capture and higher overall efficiency.

- Q: What is 3d solar cell? And anybody know any manufacturers?

- 3d solar cell is 3-dimensional silicon solar cell, which is is designed to maximize the conversion of sunlight into electricity.

- Q: What is the impact of temperature fluctuations on solar cell efficiency?

- Temperature fluctuations can have a negative impact on solar cell efficiency. When temperatures increase, solar cell performance can decrease as the excessive heat reduces the electrical output. Conversely, in colder temperatures, solar cell efficiency can improve slightly. However, overall, temperature fluctuations can lead to fluctuations in solar cell output, affecting the overall efficiency and productivity of the system.

- Q: What are the disadvantages of using solar cells?

- Some disadvantages of using solar cells include high initial costs, intermittent energy production due to weather conditions, the need for large areas of land for installation, and the production of toxic materials during manufacturing. Additionally, solar cells have lower efficiency compared to traditional energy sources and may require additional energy storage systems for uninterrupted power supply.

- Q: What is the effect of dust or dirt on solar cell performance?

- The effect of dust or dirt on solar cell performance is that it reduces the amount of sunlight reaching the solar cells, thereby decreasing their efficiency and overall power output.

- Q: What is the working principle of a solar cell?

- A Solar cell works by using the sun's energy to enable electrons in semiconducting materials to move from orbits close to the nuclei of their atoms to higher orbits where they can conduct electricity.

- Q: Can solar cells be used in telecommunications systems?

- Yes, solar cells can be used in telecommunications systems. Solar cells are capable of converting sunlight into electricity, which can power various telecommunications equipment such as base stations, repeaters, and remote monitoring systems. This allows for reliable and independent power supply in remote areas or during power outages, making solar cells an energy-efficient and sustainable solution for telecommunications systems.

- Q: How is the solar cells factories working in China? Do they follow certain quality standards?

- The solar cells factories are pretty good, at least based on my personal experience. I went to visit one of the solar cell factory based in Shandong province, and they are quite professional.

Send your message to us

Solar Energy - Best Quality Flexible Solar Cells with CE, RoHS, ICE Certification

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 500 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords