Moisture Resistant Gypsum Ceiling Tiles - Gypsum Ceiling PVC Laminated F3

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Plasterboard is made of high-grade environmental protective gypsum raw material, no harming to human body, and it has some performances: (such as environmental protection, fire-proof, moisture-proof, light and high intensity).

Plasterboard is easy to install, and its decoration effect is good. Its special indoor temperature adjustment function can provide a comfortable living environment. It is the first choice to interior decoration.

Plasterboard is made of high-grade environmental protective gypsum raw material, no harming to human body, and it has some performances: (such as environmental protection, fire-proof, moisture-proof, light and high intensity).

Product Applications:

+ Furred ceiling

+ Interior wall cover

+ Partition wall

1.Thermal insulation

2.Fire-resistant performance for fire-proof plasterboard

3.Water-resistant performance for water-proof plasterboard

4.Easy installation (it can be easily sawed,planed,holed and sticked)

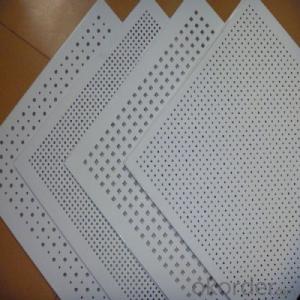

5.Special respiratory function (it has a great mass of ting holes

Product Advantages:

1.Thermal insulation

2.Fire-resistant performance for fire-proof plasterboard

3.Water-resistant performance for water-proof plasterboard

4.Easy installation (it can be easily sawed,planed,holed and sticked)

5.Special respiratory function (it has a great mass of ting holes and its function of moisture-adsorbing and moisture-dismissing)

Main Product Features:

Material: Gypsum Board, non asbestos, sulfate free

Surface: High quality PVC/Vinyl

Backside: High quality aluminized PET foil

Edges: Square

Weight /cbm: 780kgs/m3

Tolerance: Length: ± 1.0mm, Width: ± 1.0mm,

Thickness: ± 0.5mm

NRC: 0.1 - 0.3

Light reflection: 0.75

Standards: Gypsum boards are manufactured according to EN-520, ASTM C1396, E84 and E96

Humidity resistance: up to 95% relative

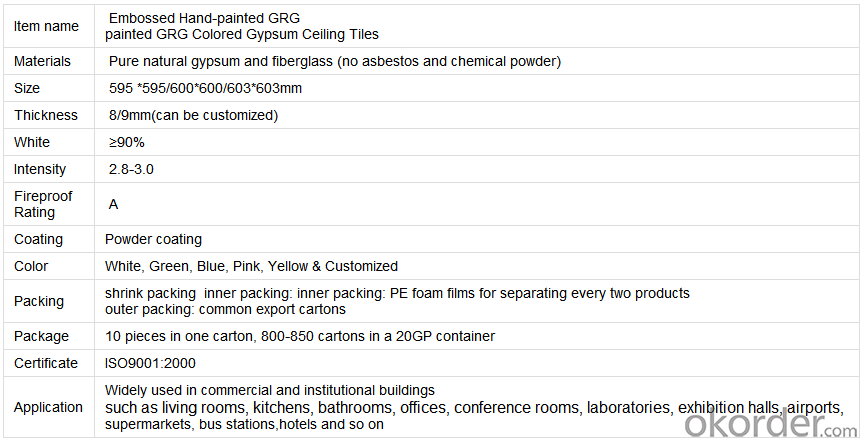

Product Specifications:

FAQ:

1. What kind of certificate do you have?

ISO9001, ISO14001, CE, SONCAP, VOI(CO), CARB, FSC, CE

2. What color can you produce?

You can choose the design you want

3. How about the delivery time?

20-25 days after receiving prepayment or L/C

For the samples, it will be prepared ASAP.

4. What's the MOQ and Payment Terms?

Minimum Ordering Quantity: 2X20ft Container

Payment Terms: T/T or L/C at sight

Images:

- Q: Is the gypsum line calculated by the perimeter of the house ceiling or by the total perimeter of the gypsum line?

- According to the perimeter of the ceiling, after all, when the gypsum line in the use of cutting!

- Q: Balcony top is looking for someone to use their own steel seal, and then the ceiling decoration company said that with the sauna board ceiling, but the workers said the sauna board is not good, easy to deformation, not insulation, said another ecological wood is better, I first decoration, Do not understand, please expert help.

- Sauna board ceiling is made of wood as raw material, through anti-corrosion, anti-cracking and other treatment, it is suitable for balcony ceiling decoration, and decoration can give people a relaxed, natural feeling. Sauna board used as a balcony ceiling, and then put some plants to decorate the balcony ceiling dress up. Natural pastoral style, a small balcony to dress up, soak a cup of tea, holding a book, take a rocking chair, enjoy the relaxed leisure time.

- Q: Ask the living room ceiling to do light, gypsum board should be done wide

- Look at the size of your living room to the top. Half the width of 400-600

- Q: Gypsum board two faces which face up to install the ceiling

- Seal processing (1) modulation of one-component caulking plaster putty The container used for modulation must be clean. According to the provisions of the proportion of the first clean water will be poured into the container, and then slowly to the water cast gypsum powder, let it swell 5min, and then stir the stir bar into a slurry without caking thick slurry, Modulation of a good pulp, can no longer add gypsum powder, so as not to agglomerate. Generally applicable to the construction time of 45min, more than time to start solidification, can not be used. (2) Board edge treatment The edge of the sheet is not treated, and the cut edge of the board should be treated as follows: Before the board is installed, gently press the front edge of the cardboard side and then use the knife Chamfer the side of the paper to pick the upper layer, and pick the open face paper torn, pay attention to the gypsum core can not be exposed, this part still keep the paper under the paper. (3) capping process With a small scraper will be stitched putty evenly embedded in the lower part of the gap between the joints, so putty squeeze the back panel side, to form a protruding putty along the mouth, so that the edge of the board with the stopper putty more firmly. Until the putty completely dry, with electric or manual sander, No. 2 emery will be slit plaster putty polished. And then with the entire paper gypsum ceiling decoration construction.

- Q: To prevent gypsum board ceiling split in addition to paste kraft paper and cloth what good way?

- 1, keel system check is good, large area should be arch. 10 meters long, from arch 1-2cm; 2, more than 10 meters long ceiling should be set expansion joints; 3, gypsum board fixed check again to see if there is no fixed fixed; 4, with gypsum-based powder approved in the gypsum board than with the old powder putty batch on the gypsum board sinking much less impact; 5, with high-quality gypsum board caulking paste to do the joint treatment, the proposed Lafarge, Pratt, Knauf, Long card and other brands.

- Q: Ceiling mounted ceiling lights, online and so on

- The heavy quality of the ceiling can be directly fixed on the ceiling, but not fixed on the ceiling of the gypsum board, is fixed in the gypsum board behind the wooden keel, behind the wooden keel to ensure that is affordable, too heavy light It is necessary in the ceiling before the closure of the original building on the top of the expansion bolts, or with angle racks, or hanging with a chain chandelier, can not hit the wooden keel.

- Q: Living room aisle hit a few rectangular frame, suitable to install what light?

- Gypsum line need to do the reason: this line will not be exposed to the outside, more secure.

- Q: How do you handle the plaster slabs?

- With gypsum powder mixed white latex or polyethylene glue, but now there is no need to adjust the anti-crack sale, the price is relatively high, but the effect is not gypsum powder is good, even after filling the gap, and then outside the gauze belt (kraft paper than gauze belt, There is a new type of fiberglass mesh belt) and then putty putty.

- Q: 10 square ceiling about how much gypsum board and wood side also need something else?

- Flat top if there is no shape of the material there; gypsum board 3 wooden side of a bundle of 2 * 3 6 bundle .3.0 straight nail 2 boxes up wire 20 steel row 3.8 a box of fast wire 200 about these

- Q: What is the general use of materials in the ceiling?

- Quality Standard 1, to ensure that the project: light steel keel and cover panel types, specifications and fixed methods must meet the design requirements; light steel keel installation must be correct, connected firmly, no loosening; cover panel should be no delamination, warping, , Missing edges and other defects, the installation must be strong, no loosening. 2, the basic items: light steel skeleton of the boom, large, medium and small keel should be the right position, straight, no bending, no deformation, hanging pieces, connectors should meet the requirements;

Send your message to us

Moisture Resistant Gypsum Ceiling Tiles - Gypsum Ceiling PVC Laminated F3

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords