Laminated Gypsum Ceiling Board - PVC Laminated Gypsum Ceiling Tiles

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 4000 m²

- Supply Capability:

- 40000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Applications:

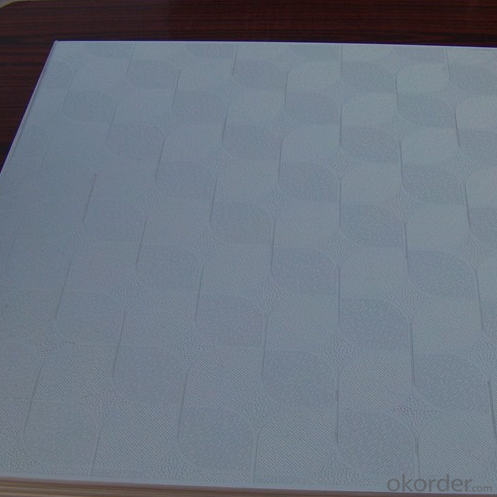

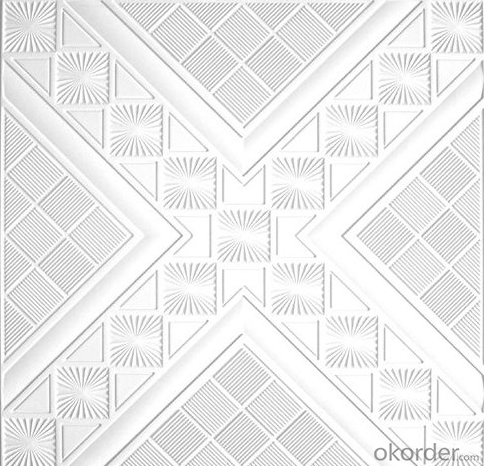

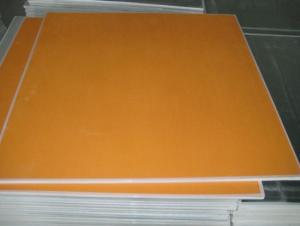

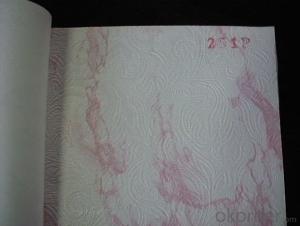

1) PVC facing and foil backing,good appearance;

2)Edge: Square,easy to install;

3)Thickness:8mm,strong enough.

Advantage:

1)Environment protection product, high quality product without any harmful substances,comfortable to live in;

2)Surface treatment is PVC film Laminated on the front side and aluminum pet foil on the back side,very easy to clean, good light reflection,Corrosion proof;

3) Materials and accessories are manufactured by state of the art technology in accordance with international standard,so after you buy this material no need worried about the safety problem.

Product Advantages:

Gypsum Ceiling is widely used in all commercial and dust-free buildings such as computer rooms, food processing electronics and pharmaceutical companies offices, hospitals, schools, restaurants and shops.

ceiling drywall metal stud for use as the standard head and in non-load bearing partition systems.

1. Our Light-steel Keel is made of galvanized steel sheet with good rust-Proof function.The thickness is strictly according to the international demand.

2. During production of the keels, it's favourable to set some fillisters and cams in both sides of the keels in a selective way, in order to strength the keels' vertical points and intensity.

3.One of our merits is the special hole for channel on C-stud in per 6Ocm which is easy for workers to install the electric lines and water tubes.

4.When intalling the plaster splint, our keels are easy to fix up, which is not only good for implaster splints and the keels as well as the whole constructure's intensity.CH and IH type of studs are the special type we developed to solve the difficult situation in elevator ventilator and offer a better protection of workers' safety.

5.Our light steel keels are in all kinds of types, we are able to manufacture German, Japan and Aus-American types etc, and we are capable of producing any special types of products and developing new products

Main Product Features:

PRODUCT NAME | PRODUCT MARK | DEMENSION(MM) | REMARKS |

COVERING CHANNEL | DC60 | 60*27*0.6 | LENGTH CAN BE PROVIDED |

DC50 | 50*19*0.5 | ||

DC50 | 50*19*0.6 | ||

SUPPORTING CHANNEL | DU60 | 60*27*1.2 | |

DU50 | 50*15*1.2 | ||

DU38 | 38*12*1.0 | ||

COVERING CHANNEL | QU | 50*40*0.6 | |

75*35*0.6 | |||

100*35*0.6 | |||

150*40*0.6 | |||

SUPPORTING CHANNEL | CU | 50*45*0.6 | |

75*45*0.6 | |||

100*45*0.6 | |||

150*45*0.6 |

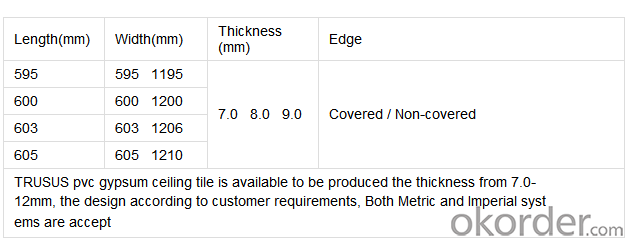

Product Specifications:

Images:

- Q: What is the difference between the PU angle and the gypsum angle?

- Pu angle: 1.PU product is a decorative type of new materials, the main feature is very light, and fire, water, moth, mildew, anti-cracking. Construction is simple and convenient, suitable for a variety of indoor and outdoor decorative materials, is a green new decorative materials. 2. PU lines and other decorative products, can be nailed, can be sawing, planing, washable, flexible shape, no crack, no deformation, no moth, indoor and outdoor can be used. 3. Easy to install, the pattern is clear and natural, elegant and luxurious. 4. Low cost: low construction costs, simple decoration. Surface finish has been completed, can be sawed, can be nailed, sticky, than the wood cement gypsum products to save 80% of construction costs. (Construction method and wood exactly the same) 5. Environmental protection: the use of synthetic fiber as raw materials, reducing the deforestation, to the national engineering decoration non-toxic harmless green product standards. 6. Fire: the company's products through the national fire detection standards, can be fully non-spontaneous combustion, non-combustion characteristics. 7. Waterproof: no water, no water, no deformation, both mildew. Easy to clean, forever as new

- Q: Want to be in the living room and dining room around the kitchen together about 36 square feet. The middle is not hanging. Need to find someone to do it. What materials are needed. Around the ceiling + spotlights + lights with a total estimated how much cost. The Master come Thank you How much money will be budgeted together? The I do not know this is not the middle of the lamp is not included. Just do a four-week ceiling, and spotlights. (You can not buy such a expensive shot, etc.). how much is the total

- Looking for carpentry, with decorative panels and gypsum board

- Q: Some people say that the seam is really good cloth with kraft paper is good, is that so?

- If there is a fixed point in the YKB board hole, there are two ways to deal with: ??????? (1) Re-punch in the appropriate space around it. (2) with 50X50 iron thickness 3-4mm nut tightening spot welding.

- Q: Ceiling ceiling is gypsum board installed with wood screws will fall?

- But that gypsum board itself is not bearing the weight, no matter what you use the screws, must be on the keel (that is, you say the wood), large lights, then the ceiling should be added when the wood base (with blockboard ), The lamp can not be directly screwed on the gypsum board (with the addition of spotlights)

- Q: Gypsum ceiling why a long time there is a gap

- Damp, according to the climate, have to use waterproof moisture board

- Q: Built-in lamp ceiling of the living room at least how much thickness, only enough possession of light. Built-in lamp ceiling of the living room at least how much thickness, was enough possession of light? Brick wall standard What is the thickness of the cement sand? living room, bathroom, kitchen, restaurant and other ceiling height at least how much?

- Brick wall of the standard specifications are: sintered solid brick, 240 × 115 × 53, concrete block 190 × 190 × 390; sintered porous brick: 190 × 190 × 90; brick brick mortar thickness is generally 6 ~ 8mm, the most Thick 10mm; living room, bathroom, kitchen, restaurant and other ceiling at least the height of 100mm,

- Q: The top angle dimension width standard is generally how many living room two layers of plaster top angle line

- Gypsum board, ceiling, gypsum fiberboard, such as a plate said, referring to the difference between the two diagonal, is 5MM, the difference between the more laugh the better, the smaller the difference, indicating that the board Founder.

- Q: Decoration with gypsum board ceiling joints need to gap, generally stay much

- Wood keel spacing 1, with the horizontal tube to find the level of the point, with the ink bucket along the horizontal point of playing the horizontal line; 2, light steel keel: wood keel for the edge of the dragon, the lamp slot position with wood keel or woodworking board production, there are wood production office to brush fire paint, keel at least 50, spacing 30 cm is appropriate, hanging spacing 60-80 cm Is appropriate, gypsum board and board between the people to set aside 5-8 mm gap, gypsum board self-tapping screws 1-2 mm and anti-embroidered treatment, to be smooth and solid, shaped to do smooth lines; 3, wood keel: keel at least 3 * 4 or more, spacing 30 cm is appropriate, hanging spacing 60-80 cm is appropriate, hanging bar is strictly prohibited direct use of wooden wedge nails to the top, brush tight fire paint until the wood keel color can not see , The keel on a layer of full-legged rice eucalyptus core 9% board and then on the gypsum board, gypsum board and board between the people to set aside 5-8 mm gap, gypsum board self-tapping screws 1-2 mm and do Anti-embroidered treatment, to be smooth and solid, shaped to do smooth lines; 4, aluminum plate: strict requirements level, light steel keel bayonet to be aligned, keel spacing of 50 or less, hanging spacing 60-80 cm is appropriate, the board when the hand to light, so as not to press the board to the pit And the contact with the tile is not tight to use the sealant to play tight; 5, aluminum-plastic plate: wood keel at least 3 * 4 or more, spacing 30 cm is appropriate, hanging spacing 60-80 cm is appropriate, brush tight fire paint, keel on a layer of full-legged rice eucalyptus core With a universal adhesive paste aluminum-plastic plate, aluminum-plastic plate and the board between the reserved 3-4 mm gap, has been filled with other colors to play the effect of grid, to be smooth and solid, shaped to do smooth lines , The angle of the fold surface can not be broken.

- Q: Gypsum board ceiling shot hole how to make up

- The gypsum board cut to the place where the keel exposed in a corresponding playing gypsum board to make up nine can remember to be sure to leak the keel to make your plaster board fixed to the keel

- Q: How much is the light of the gypsum board?

- The material is generally between 25-90

Send your message to us

Laminated Gypsum Ceiling Board - PVC Laminated Gypsum Ceiling Tiles

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 4000 m²

- Supply Capability:

- 40000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords