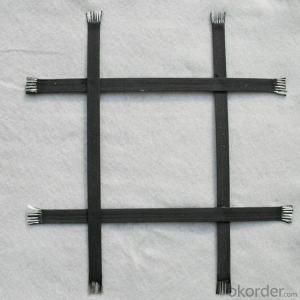

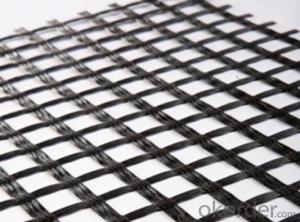

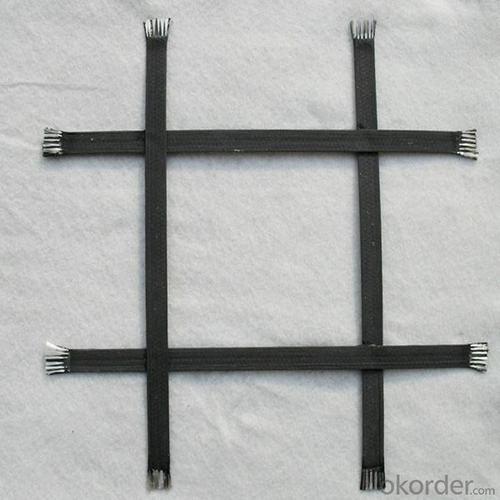

Miragrid Gx Reinforcement and Separation Geogrids for Civil Engineering Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

Type:

Geogrids

Place of Origin:

Shandong, China (Mainland)

Brand Name:

OEM or Road

Model Number:

EGA50-50, EGA80-80, EGA100-100

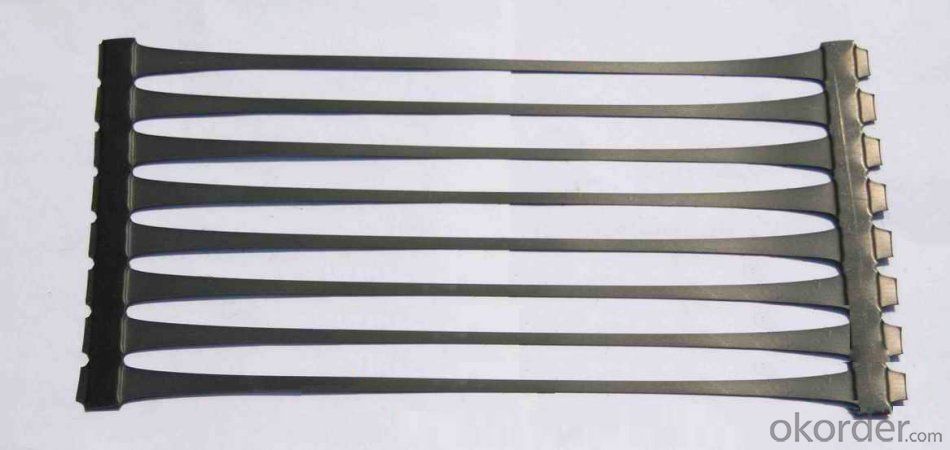

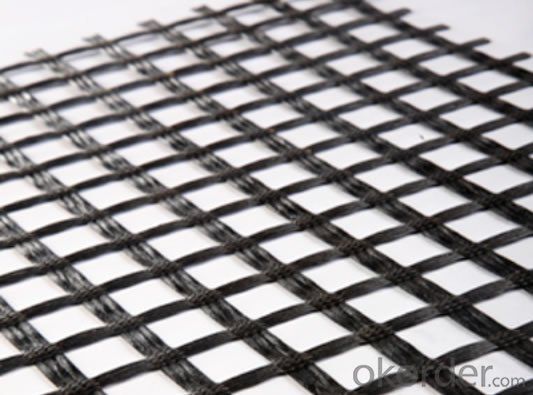

Uniaxial geo grids typically have their tensile strength in the machine (roll) direction. They are mainly used to reinforce the soil mass in a steepened slope or segmental retaining wall. On occasion, they function as a wrapping to confine the aggregate in the wire forms of welded wire faced steepened slopes.

Our niaxial geogrids are made from polyester yarn, knitted or woven into a stable structure and have a PVC or polymeric coating. These flexible, user-friendly geogrids are inert to biological degradation and resistant to creep, strain and naturally found chemicals.

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: What are the limitations of geogrids?

- Geogrids have a few limitations that need to be considered. Firstly, they are not suitable for all types of soil. They work best in cohesive soils and may not be as effective in non-cohesive or sandy soils. Secondly, geogrids have limited resistance to chemical degradation, so they may not be appropriate in environments with high chemical exposure. Lastly, geogrids are not designed to withstand heavy loads or provide significant structural support on their own, so they should be used in conjunction with other reinforcement techniques for optimal performance.

- Q: What is the effect of installation damage on geogrid behavior?

- The effect of installation damage on geogrid behavior is that it can significantly impair the performance and structural integrity of the geogrid. Installation damage can lead to the weakening or breaking of the geogrid's interlocking mechanism, reducing its ability to reinforce and stabilize soil. This can result in reduced load-bearing capacity, increased deformation, and potential failure of the geogrid system. Therefore, it is crucial to handle and install geogrids with care to minimize any potential damage and ensure optimal performance.

- Q: Can geogrids be used in temporary construction platforms for heavy equipment?

- Yes, geogrids can be used in temporary construction platforms for heavy equipment. Geogrids are strong and durable, providing stability and reinforcement to the ground. They can distribute the weight of heavy equipment, prevent soil erosion, and improve load-bearing capacity, making them suitable for temporary construction platforms.

- Q: Technical specifications of glass fiber grating

- Temperature (c) -100~280 -100~280 -100~280 -100~280 -100~280 -100~280 -100~280 (m) 1.5~4.0 1.5~4.0 1.5~4.0 width 1.5~4.0 1.5~4.0 1.5~4.0 surface treatment of 1.5~4.0 modified asphalt modified asphalt modified asphalt modified asphalt modified asphalt modified asphalt modified asphalt with excellent corrosion resistance excellent excellent excellent excellent excellent excellent

- Q: Are geogrids cost-effective?

- Yes, geogrids can be considered cost-effective. Geogrids help to improve the stability and performance of soil structures, reducing the need for excessive amounts of expensive construction materials. They also have a longer lifespan compared to traditional methods, resulting in lower maintenance and replacement costs over time. Additionally, geogrids can enhance project efficiency by reducing construction time and labor costs.

- Q: Are geogrids effective in stabilizing coastal dunes?

- Yes, geogrids are effective in stabilizing coastal dunes. Geogrids provide structural support and reinforcement to the dune system, preventing erosion and enhancing stability. They help to retain sand and prevent its displacement due to wind and water forces, thus preserving the integrity of coastal dunes.

- Q: Are geogrids suitable for use in reinforced soil slopes?

- Yes, geogrids are suitable for use in reinforced soil slopes. Geogrids are commonly used to enhance the stability and strength of soil slopes by providing reinforcement and preventing soil erosion. They are designed to distribute load and improve the overall performance of the slope, making them an effective solution for reinforced soil slopes.

- Q: What are the design considerations for geogrids in reinforced soil slopes?

- Some design considerations for geogrids in reinforced soil slopes include the type and strength of the geogrid material, proper installation techniques, adequate spacing and orientation of the geogrid layers, and the required length and width of the geogrid reinforcement. Additionally, factors such as the soil properties, slope geometry, and anticipated loads must be considered to ensure the geogrids can effectively stabilize the slope and prevent soil erosion or failure.

- Q: Fiberglass grille and geogrid which use more

- Fiberglass geogrid is glass fiber rovings as the main raw material, the reticular structure material of the knitting process, for the protection of glass fiber and improve the overall performance, through a special coating treatment process and the formation of new excellent soil substrate.

- Q: What are the applications of geogrids?

- Geogrids have various applications in civil engineering and construction projects. They are commonly used for soil stabilization, reinforcement of retaining walls and slopes, erosion control, and improving the load-bearing capacity of foundations. Geogrids also find application in road and railway construction, where they enhance pavement performance, reduce rutting, and increase overall durability. Overall, their main purpose is to provide strength and stability to different types of soil and structures, ensuring long-lasting and reliable infrastructure.

Send your message to us

Miragrid Gx Reinforcement and Separation Geogrids for Civil Engineering Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords