Melt Extract Stainless Steel Fiber RPC Dedicated Copper Military Engineering Use Steel Fiber

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 250000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: China (Mainland)

Brand Name: cnbm

Model Number: KEYOU1820

Material: Copper, Copper

Brand: cnbm

Feature: engineering steel fiber

Tensile strength: >2800MPa

Diameter: 0.18----0.30mm

Length: 6---20mm

Fulfilled standard: GJ/T3064-1999,YB/T151-1999,ASTM A820-90

Uasage: tunnels,bridges,airport road surface

Packing: in 20kg to 1 carton

Quality: good

Product features

glued steel fiber together in a row ,is used with cement for construction

oncrete steel fiber is specifically to enhance concrete in its hardened state ,the uniform distribution of steel fiber throughout the concrete greatly improve concrete bonding and tensile strength ,additionally it provides exceptional load stability and durability ,as reliable and efficient concrete reinforcement material

it is widely ued in buildings ,bridges ,thin roo engineering ,highway etc.

1.Material:high quality low carbon steel wire,copper coated

Diameter:0.18mm --0.3mm

Length: 6mm-20mm

Tensile strength:>2850Mpa

2.Feature:Excellent tensile, bending and shearing strength, resistance

against cracking, impact and fatigue.

3.Use:It is widely used for buildings, road surface, bridges, tunnels,

airport road surface, water conservancy projects, military

engineering, and all kinds of building products.

Specifications

length :20-60mm

diameter :0.5MM-1.2MM

tensile strengh:>1100Mpa

| diameter | length | tensile strength | |

| 0.5mm | 35mm | 1100Mpa | |

| 0.75 | 60mm | 1100Mpa | |

| 0.9 | 60m | 1100Mpa |

engineering steel fiber

1.it made from from wire coated copper

2.binding and shearing strength

3.Tensilestrength>2800

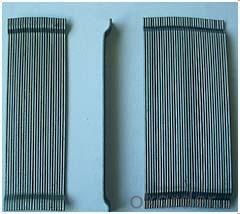

Picture

Adhesion into a row

any type steel fiber

FAQ

we can produce any type steel fiber and of course we can make production according to your requirement

we have specilize in this field for almost 10 years ,with good quality and competitive price

- Q: How does the addition of melt extract stainless steel fiber affect the setting time of concrete?

- The addition of melt extract stainless steel fiber can significantly reduce the setting time of concrete. The fibers act as nucleation sites, accelerating the hydration process and promoting the formation of calcium silicate hydrate (C-S-H) gel. This leads to a faster development of strength and an overall shorter setting time for the concrete.

- Q: Can melt extract stainless steel fiber be used in decorative precast concrete applications?

- Melt extract stainless steel fiber is a versatile option for decorative precast concrete. These fibers are frequently employed in concrete to augment its durability, robustness, and resistance to cracks. When utilized in decorative precast concrete, they can be incorporated into the mixture to offer supplementary reinforcement and prevent shrinkage cracks, which may negatively impact the final product's appearance and lifespan. Furthermore, the utilization of melt extract stainless steel fibers can enhance the overall visual appeal of decorative precast concrete. With an assortment of sizes and shapes available, these fibers enable the creation of intricate and imaginative designs. They can be utilized to generate unique textures, patterns, and finishes on the concrete's surface, thereby enriching its aesthetic allure and rendering it suitable for a wide array of decorative applications. Moreover, melt extract stainless steel fibers exhibit exceptional resistance to corrosion. This attribute proves essential for decorative precast concrete applications that are exposed to harsh environmental conditions or situated in areas with high moisture levels. Consequently, the concrete remains intact and retains its appearance over time. To sum up, melt extract stainless steel fiber offers a viable choice for decorative precast concrete applications. It enhances strength, resilience, and crack resistance, while also facilitating creative designs and maintaining the desired aesthetic appeal.

- Q: What are the properties of melt extract stainless steel fiber?

- Melt extract stainless steel fiber is a type of fiber that is formed through the extraction process of molten stainless steel. It possesses several properties such as high temperature resistance, excellent corrosion resistance, good mechanical strength, high electrical conductivity, and thermal conductivity. Additionally, it has a long lifespan, is non-magnetic, and can be easily blended with other materials, making it suitable for various applications in industries like construction, automotive, textiles, and electronics.

- Q: What is the lifespan of concrete reinforced with melt extract stainless steel fiber?

- The lifespan of concrete reinforced with melt extract stainless steel fiber can vary depending on various factors such as the quality of the concrete mix, the environmental conditions it is exposed to, and the maintenance practices followed. However, on average, this type of reinforcement can significantly extend the lifespan of concrete compared to traditional reinforcement methods. It can enhance durability, increase resistance to cracking and corrosion, and improve structural integrity, potentially leading to a longer service life for the concrete.

- Q: What is the effect of melt extract stainless steel fiber on the thermal conductivity of concrete?

- The inclusion of melt extract stainless steel fiber in concrete can significantly improve the thermal conductivity of the material. Stainless steel fibers have excellent thermal conductivity properties, meaning they can efficiently transfer heat throughout the concrete. When these fibers are added to the concrete mix, they form a three-dimensional network that helps to conduct and distribute heat more effectively. This enhanced thermal conductivity can have several positive effects on the concrete's performance. Firstly, the increased thermal conductivity can improve the overall thermal efficiency of structures built with this type of concrete. It allows for better heat transfer, which can help regulate temperatures more efficiently, reducing the need for additional insulation or heating and cooling systems. Additionally, the improved thermal conductivity can also enhance the durability of the concrete. By evenly distributing heat and minimizing temperature gradients, the risk of thermal cracking and damage due to thermal expansion and contraction is reduced. This is especially beneficial in environments with significant temperature variations. Moreover, the higher thermal conductivity provided by melt extract stainless steel fiber can also be advantageous in applications such as radiant floor heating systems. The fibers can efficiently transfer heat from the heating elements to the surface, resulting in more efficient and effective heating. In summary, the inclusion of melt extract stainless steel fiber in concrete significantly enhances its thermal conductivity. This improvement can lead to increased thermal efficiency, improved durability, and better performance in various applications where heat transfer is a critical factor.

- Q: Is melt extract stainless steel fiber suitable for use in tunnel lining construction?

- Yes, melt extract stainless steel fiber is suitable for use in tunnel lining construction. It provides enhanced strength, durability, and resistance to corrosion, making it an ideal choice for reinforcing concrete in tunnels.

- Q: Can melt extract stainless steel fiber be used in earthquake-resistant concrete structures?

- Yes, melt extract stainless steel fiber can be used in earthquake-resistant concrete structures. Stainless steel fibers are known for their high tensile strength and excellent ductility, making them ideal for enhancing the toughness and durability of concrete. When added to concrete, these fibers can improve its resistance to cracking, shrinkage, and spalling during seismic events. The use of stainless steel fibers in earthquake-resistant concrete structures can help mitigate the detrimental effects of earthquakes. The fibers act as reinforcement, providing additional strength and preventing the propagation of cracks in the concrete. This reinforcement improves the overall structural integrity of the concrete, making it more resistant to the dynamic forces generated by earthquakes. Moreover, melt extract stainless steel fibers have a high melting point, corrosion resistance, and excellent thermal stability. These properties make them suitable for long-term applications in harsh environments, such as earthquake-prone areas. The fibers do not degrade over time, ensuring the long-term durability and effectiveness of the concrete structure. Additionally, melt extract stainless steel fibers have been extensively tested and proven to enhance the seismic performance of concrete structures. They comply with various international standards, such as ASTM and ACI, which ensure their quality and reliability. These fibers have been successfully used in a wide range of earthquake-resistant applications, including bridges, tunnels, high-rise buildings, and industrial structures. In conclusion, melt extract stainless steel fiber can indeed be used in earthquake-resistant concrete structures. Its high tensile strength, ductility, and resistance to cracking make it an excellent reinforcement material for enhancing the durability and seismic performance of concrete. By incorporating stainless steel fibers into concrete, engineers can effectively improve the resistance of structures to seismic forces, ensuring the safety and longevity of the infrastructure in earthquake-prone regions.

- Q: Are there any limitations or disadvantages of using melt extract stainless steel fiber?

- Yes, there are several limitations and disadvantages of using melt extract stainless steel fiber. Firstly, one limitation is its high cost. Melt extract stainless steel fiber is more expensive compared to other types of steel fibers. This can make it less economical for certain applications, especially for large-scale projects. Secondly, the fiber length is typically short, which can limit the reinforcement effectiveness in certain applications. Longer fibers are generally more effective in enhancing the tensile strength and crack resistance of concrete. Therefore, melt extract stainless steel fiber may not be suitable for applications that require longer fiber lengths. Additionally, the mixing process can be challenging when using melt extract stainless steel fiber. Due to its short length and small diameter, the fibers tend to clump together during mixing, making it difficult to achieve a uniform fiber distribution within the concrete mix. This can result in uneven reinforcement and reduced effectiveness. Another disadvantage is the potential for corrosion. Although stainless steel is known for its corrosion resistance, it is not completely immune to corrosion. In certain aggressive environments, such as those with high chloride content or acidic conditions, the stainless steel fibers can still corrode over time. This can lead to degradation of the concrete's mechanical properties and reduced durability. Lastly, the use of melt extract stainless steel fiber may require modifications to existing construction practices. Contractors may need to adjust their mix designs and concrete placement techniques to accommodate the addition of fibers. This can result in increased complexity and potential delays in construction projects. In conclusion, while melt extract stainless steel fiber offers several advantages in terms of improving concrete's mechanical properties, it also has limitations and disadvantages. These include high cost, short fiber length, challenges in mixing, potential corrosion, and modifications to construction practices. Therefore, it is important to carefully consider these factors before deciding to use melt extract stainless steel fiber in a construction project.

- Q: Can melt extract stainless steel fiber be used in structural repair applications?

- Yes, melt extract stainless steel fiber can be used in structural repair applications. This type of fiber is made by melting stainless steel and then rapidly extracting it into filaments, resulting in a strong and durable material. Due to its high strength and corrosion resistance, melt extract stainless steel fiber is commonly used in concrete repair and reinforcement applications. It can be added to the concrete mix to enhance its structural integrity, increase durability, and prevent cracking. This fiber can also be used to repair damaged structures by adding it to the repair mortar or concrete to strengthen the repaired area. Overall, melt extract stainless steel fiber is a suitable choice for structural repair applications due to its excellent mechanical properties and ability to enhance the performance and longevity of repaired structures.

- Q: Can melt extract stainless steel fiber be used in nuclear power plant applications?

- Indeed, melt extract stainless steel fiber finds utility in nuclear power plant applications. Its exceptional corrosion resistance, high temperature tolerance, and commendable mechanical properties render it suitable for an array of pivotal roles within these plants. These roles encompass reinforcing concrete structures, augmenting the thermal and mechanical attributes of concrete, and fortifying the overall structural integrity of the facility. Moreover, the employment of stainless steel fibers bolsters the resistance to radiation damage, a pivotal requirement in the nuclear power plant setting. Thus, melt extract stainless steel fiber emerges as a dependable and efficient material for utilization in nuclear power plant applications.

Send your message to us

Melt Extract Stainless Steel Fiber RPC Dedicated Copper Military Engineering Use Steel Fiber

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 250000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords