Custom Packaging Tape NYC - Masking Adhesive Tape High Temperature Polyester Silicone

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 roll

- Supply Capability:

- 500000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Features

♦ High temperature resistant

♦ Silicone adhesive,no glue residue

♦ Best die-cut tape to mount various of precison molded parts

♦ Powder coating masking

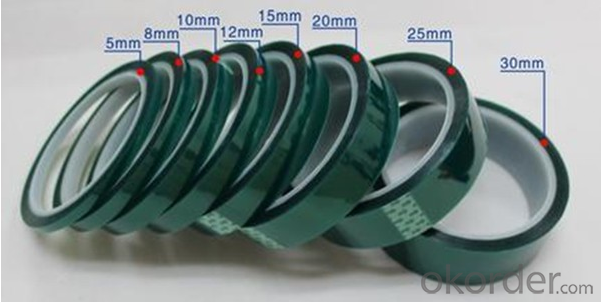

2.product show

3.Why choose us

CNBM International Cooperation is a subsidiary company of CNBM Group, which is one of the biggest state-owned company and Fortune 500 companies in the world.

All of our products are very affordable as a result of being produced in special economic development regions of China and we are more than happy to help you with the import/exportprocess too!

4.Our Services

(1)24 hours prompt reply by email or telephone or messenger.

(2)Standard size have stock, immediately delivery once your purchase

(3)10 days delivery containers for out of stock

(4)Can combine containers with multiple insulation products for your different demand

(5)No quantity limit, from 1 rolls to full container, at your choose and demand!

5.FAQ

1.Q:What's your payment terms?

A:L/C

2.Q:When could you send me the samples

A:2-3days

3.Q:Can I customize the strip length?

A: Yes

4.Q:Do you also sell other kinds led lights?

A:Yes, we also supply PVC tape, Warning tape, Fiberglass tape, Kraft adhesive tape, Aluminum Foil Tape, Foam double side adhesive tape etc.

- Q: Is packaging tape safe to use on plastic cutting boards?

- Packaging tape is indeed a safe option for plastic cutting boards. Its design enables it to stick to various surfaces, including plastic, without causing any harm or damage. It is commonly utilized for sealing packages and boxes, and does not contain any hazardous chemicals or substances that could jeopardize the plastic cutting board or the food being prepared on it. Nevertheless, it is crucial to acknowledge that utilizing packaging tape on a cutting board is not advised for reasons related to food safety. To avoid potential contamination, it is recommended to employ food-grade materials like food-safe adhesive tape or rubber bands to secure plastic cutting boards.

- Q: Due to delivery to customers, buy sealed box with more than 3 thousand yuan, borrow? The loan? Thank you!

- Can first enter the stock, low value, easy to consume goods accountedBorrow: packages and low value consumables

- Q: Does packaging tape come in different lengths for convenience?

- Packaging tape indeed comes in various lengths for ease of use. Different packaging tasks can be accommodated with packaging tape of different lengths. The commonly found lengths for packaging tape are 55 yards (50 meters) and 110 yards (100 meters). These lengths are specifically chosen to address diverse packaging needs and to ensure that there is an ample amount of tape to securely seal multiple packages without any shortage. Furthermore, the availability of different lengths provides the flexibility of selecting the most appropriate quantity of tape for individual packaging requirements, ensuring both convenience and cost-effectiveness.

- Q: Can packaging tape be used for sealing ceramic items?

- Yes, packaging tape can be used for sealing ceramic items. Packaging tape is designed to be strong and durable, making it suitable for securing and sealing various materials, including ceramics. However, it is important to note that packaging tape may not provide the same level of protection as specialized ceramic sealants or adhesives. If you are looking for a more secure and long-lasting seal, it is recommended to use a ceramic-specific adhesive or sealant that is designed to withstand the unique properties of ceramics, such as temperature changes or moisture exposure.

- Q: Can packaging tape be used for sealing cosmetic or beauty products?

- Yes, packaging tape can be used for sealing cosmetic or beauty products. However, it is not the ideal choice as it may not provide the aesthetic appeal and professional finish that specialized packaging materials designed for beauty products offer.

- Q: What are the considerations for using packaging tape on plastic packaging materials?

- When using packaging tape on plastic packaging materials, there are several important considerations to keep in mind. These considerations include: 1. Adhesive Compatibility: It is crucial to ensure that the adhesive used in the packaging tape is compatible with the specific type of plastic material being used. Different plastics have different surface properties and may require different adhesive formulations to ensure proper bonding. For example, low surface energy plastics like polyethylene may require a tape with a specific adhesive designed to adhere to such surfaces. 2. Strength and Durability: Plastic packaging materials come in various thicknesses and strengths. When selecting packaging tape, it is important to consider the strength and durability required for the specific plastic material being used. The tape should be strong enough to securely hold the packaging together without tearing or breaking, ensuring the integrity of the package during handling and transportation. 3. Temperature Resistance: Plastic packaging materials can be sensitive to temperature changes. If the package is exposed to extreme temperatures such as heat or cold, the packaging tape should be able to withstand these conditions without losing its adhesive properties. Certain plastic materials may also shrink or expand due to temperature changes, which can affect the adhesion of the tape. Therefore, it is important to choose a tape that is suitable for the expected temperature range. 4. Residue and Damage: Some packaging tapes may leave behind adhesive residue or cause damage when removed from plastic packaging materials. This can be problematic if the packaging needs to be reused or if the plastic material is sensitive to damage. Selecting a packaging tape that is designed to be easily removable or leaves minimal residue can help mitigate these concerns. 5. Regulatory Compliance: Depending on the industry or product being packaged, there may be specific regulations and standards that need to be followed. It is important to ensure that the packaging tape used complies with any applicable regulations, such as food safety standards or environmental requirements. By considering these factors, one can select the appropriate packaging tape that will effectively adhere to plastic packaging materials while also providing the necessary strength, durability, temperature resistance, and compliance with regulations.

- Q: What are the benefits of using silent packaging tape?

- There are several benefits of using silent packaging tape. Firstly, silent packaging tape provides a noise-free packaging experience. This is particularly beneficial in environments where silence is necessary, such as in offices, libraries, or other quiet spaces. By eliminating the loud noise typically associated with traditional packaging tape, silent tape helps maintain a peaceful and calm atmosphere. Secondly, silent packaging tape is preferred by employees who handle packaging tasks on a regular basis. The absence of noise during the taping process reduces the risk of noise-induced stress or fatigue, contributing to a more comfortable working environment. This can lead to increased productivity and employee satisfaction. Moreover, silent tape is a great option for businesses that prioritize customer satisfaction. When packaging items for shipment, especially fragile or delicate items, using silent tape ensures a professional and polished appearance. The absence of loud noise during the packaging process also avoids potential disturbance or annoyance to customers, both during the packaging phase and when they receive their packages. Additionally, silent packaging tape is often designed with high-quality adhesive properties. This means that it provides a secure and durable seal, keeping packages intact during transit. This reduces the likelihood of damaged goods and the associated costs of re-shipping or replacing items. Lastly, silent tape is often made from eco-friendly materials. This is advantageous for businesses aiming to reduce their environmental impact. By choosing silent packaging tape made from recyclable or biodegradable materials, companies can align their packaging practices with their sustainability goals. In conclusion, the benefits of using silent packaging tape include noise reduction, improved employee satisfaction and productivity, enhanced customer experience, secure sealing, and eco-friendliness. By opting for silent tape, businesses can create a more efficient, pleasant, and environmentally conscious packaging process.

- Q: Can packaging tape be used for sealing plastic or poly bags?

- Yes, packaging tape can be used for sealing plastic or poly bags. Packaging tape is specifically designed to provide a strong and secure seal on various surfaces, including plastic and poly bags. It has an adhesive backing that adheres well to the plastic material, ensuring that the bag remains tightly sealed. However, it is important to note that there are different types of packaging tape available, so it is recommended to choose a tape specifically designed for sealing plastic or poly bags to ensure optimal performance and long-lasting seal.

- Q: What type of rubber tape and hot-melt tape?

- Rubber tape glue is rubber as the main material, the main emphasis on grey black color.Hot melt glue cloth tape with resin as the main base, mainly yellow and white color bias.

- Q: How do I cut packaging tape without scissors?

- One way to cut packaging tape without scissors is by using your teeth. Simply hold the tape between your fingers and bite down firmly, then pull your head back to tear the tape. Alternatively, you can use a sharp object like a knife or a box cutter to cut the tape by pressing it against the tape and pulling it in a swift motion. However, be cautious when using sharp objects to avoid any injuries.

Send your message to us

Custom Packaging Tape NYC - Masking Adhesive Tape High Temperature Polyester Silicone

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 roll

- Supply Capability:

- 500000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords