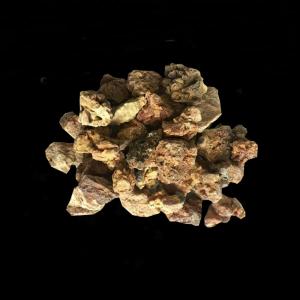

Magnesite Fused Electro-fused Magnesite FM

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Quick Details

Place of Origin: Liaoning, China

Application: Refractory

Shape: Block

Material: Magnesite

Chemical Composition: Mgo;CaO;SiO2

Mgo:96%-97%

Product name: FM

Payments terms: 1. 100% L/C at sight 2. 30% T/T prepayment, balance against BL copy

Delivery Time: Within 30 days after receiving L/C or 30% T/T prepayment

Usage: Metallurgy, Foundry, Abrasive, Refractory, Deoxidizer

Advantage: Timely Shipment, High quality, Good performance

Packing: 1mt/bag or as customers' requirements

Size: 0-30mm etc

Sample supply: free sample

Color: Brown, white

MOQ: 25Mt

Supply Ability

Supply Ability:1000 Metric Ton/Metric Tons per Month

Grade | MgO | SiO2 | CaO | Fe2O3 | Al2O3 | Loi | B.D g/cm3 |

Dicalcium-fused magnesium | 97.00 | 0.70 | 1.40 | 0.60 | 0.20 | 0.10 | 3.30-3.36 |

96.50 | 0.85 | 1.60 | 0.70 | 0.20 | 0.15 | 3.20-3.30 | |

96.00 | 0.95 | 1.90 | 0.80 | 0.23 | 0.12 | 3.20-3.30 | |

Common fused magnesite | 97.20 | 0.80 | 1.10 | 0.60 | 0.20 | 0.10 | 3.30-3.36 |

96.50 | 1.20 | 1.30 | 0.70 | 0.20 | 0.10 | 3.20-3.30 | |

96.00 | 1.40 | 1.50 | 0.80 | 0.20 | 0.10 | 3.20-3.30 | |

Size | 0-1mm, 0-30mm, 1-15mm, 1-30mm, 200mesh or according to customer's requirements. | ||||||

Plant photos:

Packaging & Delivery

Packaging Details1MT/bag or as customers' requirements.

Port Main port of China

Loading:

What is fused magnesite?

Fused magnesite is produced by high quality magnesite through electro- fusing, After melting, the SiO2 of material moves to the surface for the difference in the specific, so it has well grown crystals, well crystal perfection and structure homogeneity, excellent chemical stability, good corrosion resistance to slag and high strength at high temperature.

Where to apply fused magnesite?

It is widely used for gunning materials, fused magnesite ramming material, magnesite brick, magnesite chrome brick, vacuum and vacuum induction furnace, electric arc furnace refractory lining, magnesia crucible, furnace and a variety of refractory, such as large scale glass furnace by floating method, electrical furnace, convert furnace, house hold electrical appliances as electrical insulating materials,

- Q: For refractory, what is critical particle size? Thank you.

- It also refers to the largest particle size of aggregate!

- Q: Which are fireproofing external wall materials?

- 1. Acording to national standard GB8624-97, the combustion performance of construction materials are classified as: Grade-A: incombustible building material: Grade-A WW thermal insulation material which hardly burns. Grade-B1: nonflammable building material: nonflammable building material has good flame resistance. It is difficult to burn or spread in the air or at high temperature. Grade-B1: nonflammable building material: nonflammable building material has good flame resistance. It is easy to burn in the air or at high temperature, thus spreading the fire, such as wooden column, timber roof truss, timber beam and wooden stairway. Grade-B3: inflammable building material. Without fire resistance, inflammable building material is easy to burn and thus cause a fire. 2. According to fireproofing performance, external wall thermal insulation materials can be classified as: 1. Thermal insulation material with Grade-A combustion performance: WW inorganic thermal insulation material, rock wool, glass wool, foam glass, foamed ceramics and foam cement. 2. Thermal insulation material with Grade-B1 combustion performance: XPS panel after special treatment/ PU, phenolic aldehyde, gelatine powder polyphenyl granule after special treatment. 3. Thermal insulation material with Grade-B2 combustion performance: EPS, XPS, PU, PE, ETC.

- Q: How to do environmental impact assessment for refractory Co., Ltd.

- Give you a list of data, you can refer to. List of required data for environmental impact assessment 1) name, type, specification and quantity of main process equipment. 2) the supply and consumption of raw and auxiliary materials (annual consumption and unit consumption of raw materials, ingredients, electricity, new water and recycled water). 3) public utilities: power supply system: need to build several substations? What is the size of the substation? Water supply system: fresh water consumption, circulating cooling water consumption, domestic water consumption, production water consumption, fire water consumption, respectively, how much? Heating system: if the project has a self heating system, the size of heating boilers, types, scale, fuel types, sources, annual consumption, the boiler's circulating water supply.

- Q: How long is the fire endurance of Grade A fire resisting shutter

- Based on national standards GB 14102-2005 specifications. It is specified in GB 14102-2005 provides that: The fire resisting shutter whose fire endurance is not less than 3h is AAA fire resisting shutter when the unexposed surface temperature rise is used as judging condition. Therefore, it is required that the fire endurance of Grade A fire resisting shutter is 3h.

- Q: I would like to know if there is any requirement for refractories in the crucible type high-frequency smelting furnace Worry! I hope you can help me! This time!

- Stable chemical properties. The crucible material should not be hydrolyzed at low temperature. It is difficult to be decomposed and reduced at high temperature and is not susceptible to corrosion by molten slag and molten metal;

- Q: Who knows about the fire endurance of grade C fire doors?

- It can be classified according to the fire endurance and thermal insulation performance: The fire endurance of grade A fire doors is not less than 1.5 hours; that of grade B fire doors is not less than 1.0 hours; and that of grade C fire doors is not less than 0.5 hours. I hope my answer can help you.

- Q: What crusher is used for raw material of broken refractory material? What is the rough crushing process? What are the materials? Thank you!

- Now cone crusher is generally used.

- Q: What are the advantages and disadvantages of new external wall fireproof and thermal inuslation matertials?

- The new external wall fireproof and thermal inuslation matertials have both the advantages and disadvantages. Advantages: 1)Low requirements on the waterproof, weather resistance and other technical indicators. The dry wall and gypsum plastering mortar, etc. can meet the requirements and can be easily obtained; 2) The inner insulation material are separated by the floor, and construct within a height of only a storey , without erecting scaffold ; 3) In the hot summer and cold winter or hot summer and warm winter area, the inner insulation meets the requirements; 4) The glass beads overcome the shortcomings of expanded perlite, like, large amount water absorption, easy powdering, big volumetric shrinkage in the slurry mixing process, easily leading to post-insulation product performance degradation and hollowing, cracking, and also make up for the defects of polystyrene particles organic materials, like, flammable, poor fire performance, producing harmful gas at high temperatures and anti-aging, poor weather resistance, poor workability and large rebound in construction, ect. Disadvantages of external wall insulation : 1) Since the ring beam, slab and column structure would cause thermal bridges, leading a greater heat loss; 2) It is of low intensity, high water absorption, easy to shrink and crack. The insulation system is prone to cracking, leaking or loss and other common quality problems, especially it is easy to crack at the seams, thus being difficult to exsit as long as the building. 3) It is inconvenient for the users to redecorate and hang ornaments; 4) It takes up indoor used space;

- Q: What types of steel are silicious quicksand and chromium quicksand used in respectively?

- Chromium quicksand can be used in steel-making process that has longer refining time like LF, VD and RH, in stainless steel drainage and thin plate drainage agent. Silicious quicksand is used in short steel-making process, process that is less than 45 seconds or process without refining. You can consult Hua Heng for details or inspect it by yourself.

- Q: On the problem of making refractory materials

- But if only a is chosen, does it mean that as long as it is insoluble in water, it can be made of refractory material? Obviously absurd!

Send your message to us

Magnesite Fused Electro-fused Magnesite FM

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords