High Alumina Brick - Low Thermal Conductivity Diatomite Firebrick for Kiln

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

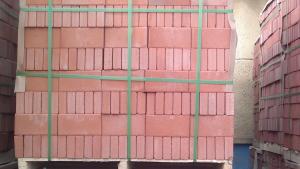

| Packaging Details: | Standard export wooden pallet with cardboard, 480pieces/pallet for standard size |

low thermal conductitity diatomite firebrick for kiln

Product Description

B series insulation bricks are made from high purity raw material according to different brick type to meet different requirement.

They are ideal thermal insulation material usually used in industrial furnaces and heating pipe.

Our insulation bricks are in accordance with JIS Industrial Standard of JAPAN, have excellent properties as light weight, low ferrous, low shrinkage, atmosphere erosion resistant and so on.

Features and advantage:

1. Light weight

2. Low density

3. High strength,good thermal shock resistance

4. Low heat storage, low thermal conductivity

5. Saving energy

6. Precise size

7. Good thermal insulation effect

8. Good quality and low price

Application:

It is widely used as a primary hot face refractory lining or as back-up insulation behind other refractory in furnace(such as carbon furnace, cracking furnace, heating furnace for oil refining, roller kiln, tunnel kiln.), flues, refining vessels, heaters, regenerators and similar high temperature industrial equipment.

- Q: What's the difference between a well type annealing furnace and a box type annealing furnace?

- RT3 series trolley type resistance furnace is a national standard energy-saving cycle type operation furnace. It has super energy-saving structure, adopts fiber structure and saves electricity 30%. Exclusive production of composite high aluminum nails group, car anti-collision sealing brick, automatic sealing trolley and furnace door, integrated rail, without the basic installation, placed on the ground floor can be used. Mainly used for high chromium, high manganese steel castings, ductile iron, roller, steel ball, 45 steel, stainless steel quenching, annealing, aging, and various mechanical parts heat treatment. Features: 1, no noise, no environmental pollution. 2, small heat storage, less heat loss. 3, high temperature control accuracy, furnace temperature uniformity. 4, a high degree of automation, simple. 5, PID programming can be used to set, fully automatic operation. 6, good sealing, long life, safe and reliable. Widely used in chemical, petroleum, food, metallurgy, machinery, light industry, electricity, ships, paper, mining, medicine, central heating and other industrial sectors. With the development of social productive forces, its application in various industries is more and more widespread. Two, pitannealingfurnace (for example: flange heat treatment furnace) use: the furnace for metal parts, such as ring of equipment heat treatment at rated temperature: the furnace is composed of furnace body and a movable furnace cover and control system.

- Q: What are the common thermal insulation materials for thermal conductivity?

- The vacuum heat insulation plate is a kind of high efficiency thermal insulation board made of inorganic fiber core material and high resistance gas composite film. It is made of vacuum encapsulation technology and covered with special interface mortar.

- Q: The cloth blowing is not uniform on the lime kiln refractory brick is damaged it

- Lining 1 yuan to prevent direct damage to the Sindh kiln high temperature flame or air, to protect the kiln carcass; 2, to prevent harmful substances (CO, SO2) erosion of the kiln body; 3, to prevent corrosion, material flow on the kiln body; 4, reduce the kiln temperature, kiln body to prevent oxidation 5, has the function of corrosion; thermal insulation; 6, to improve the coating performance.

- Q: What is the density of a super high alumina brick and what is the price?

- Of course, the transaction price, please choose refractory brick manufacturer is better.

- Q: What materials are used for roof insulation?

- There are two kinds: one is a kind of cotton insulation board, such as rock wool board, aluminum silicate cotton board, but this is not environmental protection, harmful to life, foam board (this fire safety factor minimum), these relatively cheap.

- Q: Are there any differences between insulating bricks and refractory bricks?

- Heat preservation brick is to emphasize its heat preservation performance generally, not paying much attention to its refractoriness, but refractory brick is exactly the opposite. Different locations will use different materials, I hope we can choose carefully.

- Q: How to distinguish the good or bad of the high aluminum brick?

- In the procurement of high alumina brick, the first color, high quality aluminum brick, brick surface smooth, yellow color pale, four sides equal, no broken angle, no cracks.

- Q: How are the grades of high alumina bricks differentiated?

- If the content of Al2O3 is higher than 90%, it is called corundum brick. Because of the different resources, the standards of different countries are not exactly the sameFor example, European countries limit the content of Al2O3 for high alumina refractory materials at 42%.

- Q: What causes breakage of refractory bricks?

- Refractory brick is a non metal mineral products can be used in the high temperature of 1550 DEG C under belongs to a class of inorganic, used in high-temperature furnace lining materials as protection kiln, which causes damage, usually have these points.Furnace temperature is not clear, there is no corresponding choice of refractory bricks.Physical impact, abrasion and erosion cause damageChemical factors, especially chemical industry, should be made of refractory bricks, which should be resistant to penetration and erosionIV: products from the factory when the factory did not pass the quality inspection standards

- Q: What should be used as binder for making high alumina bricks?

- In addition, high alumina micro powder can be used as binding agent, or high alumina micro powder and clay powder are prepared according to a certain proportion, and synthetic mullite is used as bonding agent. With these binders, high alumina bricks without two expansion can be prepared.

Send your message to us

High Alumina Brick - Low Thermal Conductivity Diatomite Firebrick for Kiln

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords