Laser Cutting Machine QL-1121

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 150 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

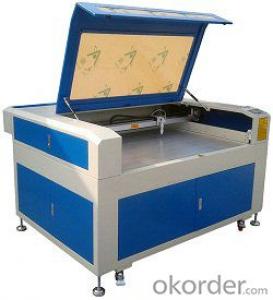

Laser Cutting Machine

High speed & Accuracy

Super quality and competitive price

Perfect after-sales service warranty

Laser Cutting Machine QL-1121

Performance Features

1.Configure higher power laser tube.

2.DSP controlling system, rich functions, can effect engraving on plane, gradient engraving by 360 degree, cutting and drilling holes etc.

3.Owns functions of restoring from power off, continuation on break point.

4.Transmit files directly in CorelDraw, AutoCAD etc.

5.Adopt international linear rail, more precision.

Model |

QL--1121 |

Working area |

160cm*210cm / 63in*83in (L*W) |

Laser power |

130w/150w |

Laser type |

CO2 sealed laser tube,water-cooled |

Cutting speed |

0-50000mm/min (0-1968 inch/min) |

Laser Output |

1-100%software setting |

Resetting positioning accuracy |

≤±0.01mm |

Power supply |

220V/50HZ , 110V/60HZ |

Operating temperature |

0 - 45°C |

Operating humidity |

5 - 95% |

Min. shaping character |

English 1.0 x 1.0mm |

Graphic format supported |

BMP, PLT, DST, DXF, AI |

Software supported |

CorelDraw, PhotoShop, AutoCAD,TAJIMA |

Driving system |

3 phases stepper motor |

Equipment Dimension | 268cm*230cm*112cm 106in*91in*44in |

Packing Dimension | 278cm*240cm*130cm 109in*94in*51in |

Net Weight |

1200kg |

- Q: Injection molding machine after opening the thimble, the top is not moving, the top of the solenoid valve, the ejection point after the lubricant, the top out of normal, work a few minutes later, and must also be sprayed, this is the point of trouble

- One, because thimble is stuck, suggest:1: check the installation of a few top rod, installed less or the location is wrong, there will be a top out, or stuck;2. check the thimble for carbon or rust;3. check that the ejection is under pressure.Two 、 injection molding machine, also known as injection molding machine or injection machine. It is a thermoplastic or thermosetting plastic plastic molding mold made of plastic products of all shapes of the main molding equipment. It is divided into vertical, horizontal and all electric type. The injection molding machine heats the plastic, applying high pressure to the molten plastic to make it crack and fill the mold cavity.

- Q: What should I do if the thimble is not unloaded on the lathe?

- With a thick iron pad back up

- Q: How to install ejector pin removing device on die cutting machine?

- Installation of thimble waste removal device can directly contact your company to buy die cutting machine manufacturers of customer service, if the service of the company will be in two or three days or even faster arrangements for your company to install. I hope I can help you!

- Q: How do we deal with the die thimble?

- Replace the point thimble directly

- Q: What is a thimble?

- The ring finger is usually made of metal or plastic, surface dent federated, the needle top cloth to protect the fingersA conical metal rod that supports workpieces on a lathe or grinder and rotates it around it

- Q: Our Chinese textbook has a thimble, I don't know what it means, I have for example: Xiao Lan trails, gas like smoke, smoke like fogJiang floor Pavilion, moonlight, such as water day

- The ejector pin is the front of the number, the same as the back. Such as: outside the Castle Peak, the mountains outside the white clouds, clouds flying outside

- Q: What are the installation methods, that kind of method can best protect coaxiality, trouble can be explained in detail, or give some reference material is best.

- The top insert thetailstock spindle taper hole standard rod end top end at the other end of the top end of the tailstock dial indicator is fixed on a middle carriage in the spindleContact with the standard gauge rod sliding carriage to adjust the headstock tailstock after adjustment can ensure the machining precision of coaxiality etc.

- Q: The mold tube thimble can not return to the designated position, the left and right sides have what is going on!

- The situation you are talking about may be the following questions,1, the thimble plate sink too deep (see what you asked, should be checked, can be ruled out)2, our tube and the mold with smooth, tight when it is heated, so that the ejector plate back in place, but this problem will lead to other thimble will back in place, and only in the back needle short will appear this situation, or to be back pressure needle. You can check this again. If only the cylinder is higher, you should see whether the front of the thimble plate is too small or not. When the tube is out of order, the tube hangs in front of it. If it's good, it won't be possible unless the cylinder is of the wrong height. Or the barrel is stretched. Ha-ha3, your cylinder fits into the cage, and the rear side of the cylinder is too small to support.4, you said "just like back in place, flash out", this sentence, you did not go to the measurement of product is not short column two mm, the two began to die well, is behind. There is also a case of ejector pin back, making our cylinder the steps below our needle tube, that will also appear flash like this to confirm the ejector pin plate bolt can lock the screw end, and big enough, if the needle is large enough, is to end lock screw. If the needle is relatively small and long, on the way to do a Tozzi gatto, syringes and needles. If the needle is broken, you want to see the length, right? Is there too much preload?

- Q: How can the thimble be fitted with bearings?

- Center mounting bearing. Refer to the structure of the rotary center, and the slewing center is used to realize the rotation of the bearing.

- Q: How can the repair of the die thimble cause friction with the die?

- First, make sure that the thimble hole on the die is large or the thimble is small.The thimble hole also needs to distinguish whether the whole hole is big or just the mouth big. The thimble needs to distinguish between the whole thimble or the small mouth.I. if there is a problem with the mouth, then:1., the thimble hole weld repair, change the upper part of the good thimble;Two. If the whole hole is large or the whole thimble is small:1. change to a slightly larger thimble;2., expand the top pin, change the size of a new thimble;2. use customized non-standard thimble with pinhole.

1. Manufacturer Overview

| Location | Shandong,China |

| Year Established | 2008 |

| Annual Output Value | US$5 Million - US$10 Million |

| Main Markets | 11.11% North America 11.11% South America 11.11% Eastern Europe 11.11% Southeast Asia 11.11% Oceania 11.11% Mid East 11.11% Eastern Asia 11.11% Western Europe |

| Company Certifications | ISO 9001:2000;CE Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | QINGDAO,TIANJIN,SHANGHAI |

| Export Percentage | 71% - 80% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English, Chinese, Russian |

| b) Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | 10 |

| Contract Manufacturing | OEM Service Offered Design Service Offered |

| Product Price Range | Low and/or Average |

Send your message to us

Laser Cutting Machine QL-1121

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 150 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords