KXT(S) Raw Meal Dosing and Control Syatem

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

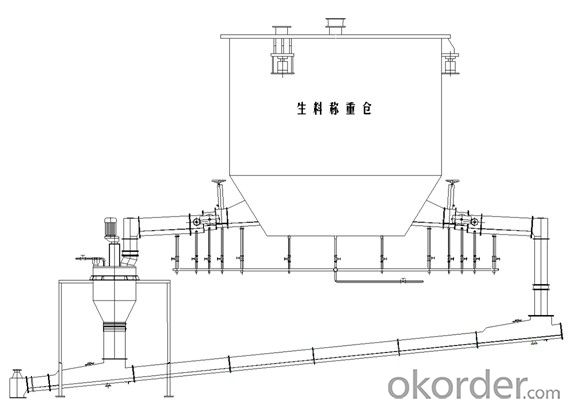

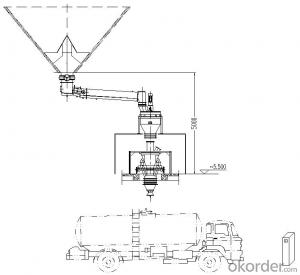

KXT(S) DOSING SYSTEM apply to raw meal dosing feeding and measurement in NSP cement kiln feeding, characterized with stable feeding, accurate dosing, rapid adjusting, zero self correcting, automatic calibration on-line etc, which is in set with the raw meal dosing feeding in 1000-5000t/d NSP cement product line.

1. Composition

This system consist of BD weight calibrate box, WG flow-stabilizing feeder, KL(S) flow meter and control system.

Weight calibrate box can demarcate the flowmeter online, dominate the material level in the box.

Regard as the pre-feeding devise, WG flow-stabilizing feeder can adjust the feeding quantity as discretion, together with the KL(S) flow meter constitute the closed loop control system. The WG flow-stabilizing feeder can feed the material according the given flux demand. The feeder include two apolegamy form , flow-stabilizing impeller and flux control valve. You can choose the apolegamy form thereinto according the different feeding quantity and material speciality. This series mainly apply as Mass-flow powdery material dosing preceding stage feeding equipment.

Control system will get the instantaneous flow after calculate the collected signal, and show the instantaneous flow and progressive volume. At the same time, the system will adjust the WG flow-stabilizing feeder base on the setting value.

2. The main technical characteristics of KXT(S) system

(1) measuring accuracy: out match 0.5%

(2) control accuracy: ±1.0%

(3)measuring range: 10~550t/h (raw material) arbitrarily selected.

(4)Suitable material: raw material, cement or other powdery and granular material.

(5)environment: temperature -20℃~60℃, relative humidity, ≤95%.

(6)Moisture of material: ≤1.5%

3.KXT(S) control system

Control system take the responsibility for accomplishing several task like signal collection, situation estimation, error correction, operation management, data display, system regulation, system communication etc.

Specification

Application scope | Cement raw material, cement, and other powder and granular materials | |||||

Model | KXT-Ⅰ | KXT-Ⅱ | KXT-Ⅲ | KXT-Ⅳ | KXT-Ⅴ | KXT-Ⅵ |

Range(m3/h) | 10~100 | 20~200 | 30~300 | 40~400 | 60~600 | 80~800 |

- Q: What is a forklift? Forklifts are special equipment

- Project code: N2 See the general administration of quality inspection (aqsiq) for the announcement of the "special equipment catalogue" in 2014 Definition of special motor vehicle in field (factory) : Special motor vehicles, in the field (factory) is refers to besides the road traffic, agricultural vehicles in the plant, scenic spots, only used in certain area such as amusement places of special motor vehicles.

- Q: Talk about how to cut the cost of moving materials.

- I think the main thing is to choose a range of suitable devices. If the moving objects and routes are relatively fixed, the use of the manipulator can be more efficient. The cost is naturally reduced.

- Q: What is the rational and scientific classification of logistics facilities and equipment

- Generally be divided into logistics facilities and equipment, logistics equipment, logistics, warehouse facilities and equipment, logistics transportation facilities and container handling equipment, logistics equipment, logistics, circulation unitized equipment, port logistics facilities and equipment processing equipment, automatic sorting equipment, information platform and equipment. Logistics infrastructure refers to the service function of a supply chain and some of the supply chain process, meet the need of logistics organization and management, which has the function of comprehensive or a single place or organization collectively, mainly including roads, railways, ports, airports, distribution center and network communication, etc. Logistics infrastructure includes warehousing, delivery facilities, and computing and information communication equipment.

- Q: The material needs to be transported, it is easy to produce dust.

- In general can be used in coal chemical industry material, and can control the dust conveying equipment are: the tube chain conveyor, screw conveyor, continuous chain bucket conveyor, bucket elevator, belt conveyor belt cover, scraper conveyor, and pneumatic conveying system and so on. If there is a technical problem, we are willing to answer for you and invite you to visit the user!

- Q: Why should we emphasize unitization and standardization in material handling

- The logistics module is the dimension of the logistics facilities and equipment. The logistics module is for the rationalization and standardization of logistics, the standard scale of various factor dimensions of the logistics system. It is composed of various factors in the logistics system of, these factors include: the group, group the goods loading and unloading machinery, transportation machinery and equipment trucks, trucks, container and transport facilities, machinery and equipment for the cargo storage, etc.

- Q: What is the material handling and handling equipment?

- . Highway transportation equipment Heavy tractor semi-trailer | van | | equipment | special transportation vehicle 9. Warehouse peripheral devices cllimbing trolley | slide machine loading and unloading platform | | | industrial door platform loading and unloading of rain loose 10. | | tray container unit equipment container bags | container net | slide 11. Forklift handling vehicle | electric flat car | | tractor attachments of ft | forklift parts 12. Manual handling equipment Hydraulic pallet truck cart hydraulic pallet stacker | | | lever type hydraulic lifting flat wagon | push car 13. Automatic sorting system, automatic sorting machine | | automatic sorting conveyor system automatic control systems and equipment

- Q: The beneficial effect of material handling machinery

- Material handling machinery is serving the production, its design and type selection should be subject to the needs of the production process, new material handling machinery but also often leads to the change and improvement of the manufacturing process. For example, the emergence of bucket wheel stacker reclaimer, formed the bucket wheel stacker reclaimer for heart, belt conveyor for blood vessels, the electronic computer is the nerve center of automation of large bulk material handling system, which changes the ports, mines and the layout of the power plant and so on of the bulk yard; It can simplify the structure of the factory and reduce the cost of construction.

- Q: Material handling system in the factory

- The machinery factory's internal logistics system involves the production plan, process flow, moving operation, warehouse management, information system and so on.

- Q: What is the relevant content of the flow of materials, storage and usage

- What is the relevant content of the flow of materials, storage and usage? Material flow, in lean as "one-piece flow," the core idea is how to make the material in the production process is in a state of flow, however it is very difficult, a more realistic approach is to ensure that in the process of circulation between the products is the least (quantity). The real meaning of storage is what you really need at the scene. Using a process is the sequence of steps to complete a task

- Q: There are three things to do when the material is stacked up and down

- Fire proof, waterproof and center of gravity

Send your message to us

KXT(S) Raw Meal Dosing and Control Syatem

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches