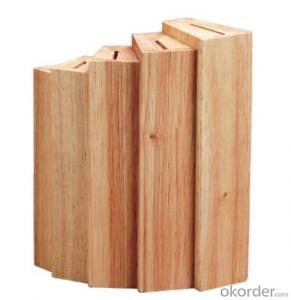

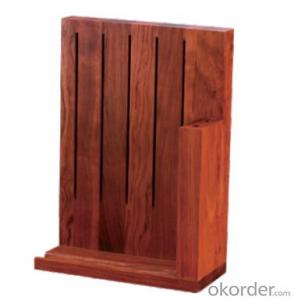

knife seat,F-KB083 Carbonized bamboo knife seat,your best choice

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

product name:rubber wood knife seat

material:Carbonized bamboo

N.W.:1.286kg

MEAS:22*16.5*15cm

Product advantage:

How does the bamboo product carbonize?Firstly,put the bamboo or bamboo bag into the high-pressure carbonized boiler of 200 degrees - 300 degrees for vapor carbonization.

And after high temperature and high pressure, so that form a hard carbide particles layer on the surface.At the same time,the bamboo itself will be more harder.

The advantage of carbonized bamboo knife seat:after carbonize,hard carbide particles will form a environment not easy living for bacteria on the surface of bamboo product to achieve the antibacterial effect.

At the same time, because after carbonization the bamboo will be more hard than ordinary paper products, preventing wearing and bamboo thorn problem.

Carbonized bamboo knife seat quantity:

Safety, health, bright color,durable,the everyday necessary good products

Anti-mildew change,anti moth

Environmental protection,no crack,no decay

- Q: Drilling out of the hole is the overall deviation, the hole is 0.15, the cutting tool angle is not biased, the product is not how to jump, I was the first drilling after the chamfer, is how to go wrong, in this case, ask the teacher, thank you first, urgent...

- Perhaps the clamping part is not strong, you look at whether the clamping, three claws excessive wear.Recommendation: 1 check the three claws.2 hydraulic chuck, increase pressure.3 chamfer first, then hit the center hole.

- Q: NC turret is not in place

- The position of the tray is misplaced, and the position is fine

- Q: What is the difference between NC machine tool and tool holder

- In front of the turret with rear turret X axis is not the same, the general system programming does not have what difference, the front turret program got rear turret lathe bed on the same processing, but also have different, like Beijing DTM window system, front and rear arc knife tool that is just the opposite.

- Q: Oblique bed CNC lathe in the row on the turret mounted electric turret, and then install the power head, you can also install the tailstock, I do not know this? Cheap not?

- Row lathe generally does not install tailstock, it will lose the advantage of the knife.Others can be added, according to the need to add, not excess.

- Q: How to maintain the lathe tool holder

- If the positioning and clamping action is normal, the push rod 11 is in contact with the corresponding contact 12, and the signal is sent to indicate that the tool changing process has ended, and the cutting process can be carried out.In addition to the positioning of the hydraulic cylinder and the positioning pin, the motor can also be used to drive the clutch to locate, as well as other indexing and positioning mechanisms.

- Q: Tool holder S solution

- Vertical typeThe wheel frame, in fact, is a parallel steel frame structure.Than S, there are many advantages.For example, solid, DIY, modification, etc.

- Q: However, No. 2, No. 3, the normal use of potential energy on the knife No. 4 can not be normal use of the rotation has not stopped on the 1.

- Holzer component position (open the top cover can be seen as commonly referred to as the disk) is not right or damaged. Has not been able to stop because of the knife can not find the signal in place 4.

- Q: CNC lathe hit the knife after the knife center height, how to deal with?

- The change of the center height of the tool holder can be adjusted on the height of the knife.

- Q: What is the material of the cutting tool

- One, the tool holder commonly used materials:High carbon steel is often referred to as tool steel, mainly used in the manufacture of cutting tools, etc.. The characteristics of its carbon content from 0.60% to 1.70%. is hard and brittle, can be quenched. Hammers, crowbars and other by carbon 0.75% steel; cutting tools such as drills, taps, reamers, made of carbon steel 0.90% to 1%. High hardness (HRC60 65) and good wear resistance can be obtained after heat treatment. 2, under the condition of annealing hardness is moderate, has good machinability. 3, easy access to raw materials, low production costs.Two, blade commonly used materials:1, high speed steel (also known as Feng Steel, Bai Gang): is a kind of tungsten, chromium, vanadium, molybdenum and other high alloy tool steel more elements.2, tungsten carbide hard alloy by high hardness and melting point, titanium carbide and cobalt cemented metal made by powder metallurgy method, the hardness and wear resistance are good, hot hardness is very high, so the cutting speed is higher than high speed steel several times or even several times, can cut material of high speed steel no processing method, but the bending strength and impact toughness of high speed steel much worse than.3, ceramics: alumina powder sintered at high temperature and the ceramic blade, the hardness, wear resistance and heat resistance are higher than the cemented carbide.

- Q: Where are the Holzer elements in the CNC turret?

- A cutter position corresponds to a Holzer element, usually enclosed in a round plastic box

Send your message to us

knife seat,F-KB083 Carbonized bamboo knife seat,your best choice

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords