knife seat,F-KB085 Carbonized bamboo knife seat,your best choice

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

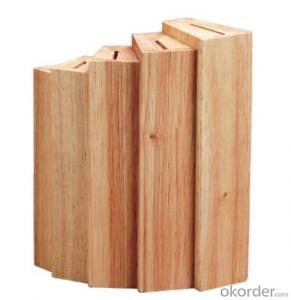

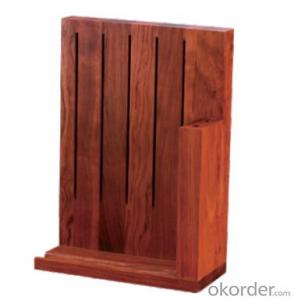

product name:rubber wood knife seat

material:rubber wood

N.W.:1.464kg

MEAS:22*28*7.5cm

Product advantage:

How does the bamboo product carbonize?Firstly,put the bamboo or bamboo bag into the high-pressure carbonized boiler of 200 degrees - 300 degrees for vapor carbonization,and after high temperature and high pressure, so that form a hard carbide particles layer on the surface.At the same time,the bamboo itself will be more harder.

The advantage of carbonized bamboo knife seat:after carbonize,hard carbide particles will form a environment not easy living for bacteria on the surface of bamboo product to achieve the antibacterial effect.At the same time, because after carbonization the bamboo will be more hard than ordinary paper products, preventing wearing and bamboo thorn problem.

Carbonized bamboo knife seat quantity:

Safety, health, bright color,durable,the everyday necessary good products

Anti-mildew change,anti moth

Environmental protection,no crack,no decay

Primary Competitive Advantages:

Brand-name Parts Country of Origin

Distributorships Offered Experienced Staff

Form A Green Product

Guarantee/Warranty International Approvals

Packaging Price

Product Features Product Performance

Prompt Delivery

Main Export Markets:

Eastern Europe North America

Mid East/Africa Central/South America

Asia Western Europe

Australasia

- Q: How to do the slide shoe

- A few days ago did not see that the answer is late, sorry! You are flat shoes? If so, can the nail be taken out? If you can not get out, such as the two floor, said the first to use an electric drill to destroy it (beware of injury to the knife). If you can take out but not screwed tight, you can find a pair of casual shoes (is that the plastic knife style kids skating shoes), the shoes on the nail are two sides of screw thread nail (nail is not the same as the flower of peace), can not rely on the original screw tightening tool wear nail; but the best in the middle of a cushion spring washer what, lest loose danger.

- Q: In front of the turret with rear turret in the car to count the G41G42 cutter compensation when there is no difference?

- The turret of the numerical control lathe is the front knife holder in the operator's side.The common lathe is the rear cutter.When the tool head, the G42 tip radius compensation right bias in the car when the hole, when the car is round with G41.

- Q: How to maintain the lathe tool holder

- Open the check, the ordinary lathe turret with old and new, open to find the damage in, say, the old pine lock off directly to lift the knife can be removed, the demolition of a new week is generally anti remember screw wire, remove the cover, which can disassemble parts, slowly observe there is a problem, most are rust, dirt and ash layer thickness will not cause, no live, no obvious wear and tear after cleaning equipment on the lookout to adopt good.

- Q: What is a tray roll bag

- The plastic bag used to cover the tray is polyethylene (LDPE)Partial contraction and contractionConventional size is 1 m 2*1 m height is not limited to 2. Then the household garbage bags are collected on the paper tubeIndustrial heat shrinkable tray with a roll bag weight is about 1 kg.

- Q: What is the tool rest

- The tool holder is arranged in order to prevent the workpiece from being bent and deformed when the workpiece is cut by the cutter, so that the diameter of the part is larger. Is in the process of moving together with the head.

- Q: These possibilities have been tested, or useless

- If the CNC bending machine, please check the machine parameters of the return voltage, and finally close to the voltage value, you can adjust it.

- Q: 4 station tool structure is the best. The detailed process of mechanical transmission, their demolition a few times, the worm brake to lift the knife. There is a problem in the rise of the knife in the process of the top cap of the spring to the top of the iron cover dead, the result of the death of the knife holder, can not drive. I estimate that the top cap and the angle and the first bevel on the iron cover are not consistent due to wear and tear. For I a person's opinion, hope you enlighten me

- This thing to have a picture to explain, the text can not express. Remove the countless times, the rotation of the motor makes the knife rises and then rotating, on top of a Hall element to detect the Holland tool you need is not to, to the motor reversal, falling knife stuck in the tooth is motor locked dead. There is a spring in the middle of the shaft and drives the two clips to play a key role. A lot of reasons for the death of the tool holder are caused by the broken line in the middle.

- Q: What is the material of the cutting tool

- One, the tool holder commonly used materials:High carbon steel is often referred to as tool steel, mainly used in the manufacture of cutting tools, etc.. The characteristics of its carbon content from 0.60% to 1.70%. is hard and brittle, can be quenched. Hammers, crowbars and other by carbon 0.75% steel; cutting tools such as drills, taps, reamers, made of carbon steel 0.90% to 1%. High hardness (HRC60 65) and good wear resistance can be obtained after heat treatment. 2, under the condition of annealing hardness is moderate, has good machinability. 3, easy access to raw materials, low production costs.Two, blade commonly used materials:1, high speed steel (also known as Feng Steel, Bai Gang): is a kind of tungsten, chromium, vanadium, molybdenum and other high alloy tool steel more elements.2, tungsten carbide hard alloy by high hardness and melting point, titanium carbide and cobalt cemented metal made by powder metallurgy method, the hardness and wear resistance are good, hot hardness is very high, so the cutting speed is higher than high speed steel several times or even several times, can cut material of high speed steel no processing method, but the bending strength and impact toughness of high speed steel much worse than.3, ceramics: alumina powder sintered at high temperature and the ceramic blade, the hardness, wear resistance and heat resistance are higher than the cemented carbide.

- Q: How do you know how to install the roller skates?

- When installing tool holder is according to personal habits, but most were filled with the knife knife mounted on the middle sole. That is, the wheel is about the same length as the shoe.

- Q: Where are the Holzer elements in the CNC turret?

- Holzer components in the tool holder is called a disk. I have a detailed look at the space

Send your message to us

knife seat,F-KB085 Carbonized bamboo knife seat,your best choice

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords