JLP-120 Automatic Bottle Unscrambler Made In China Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Product ShortDesc:

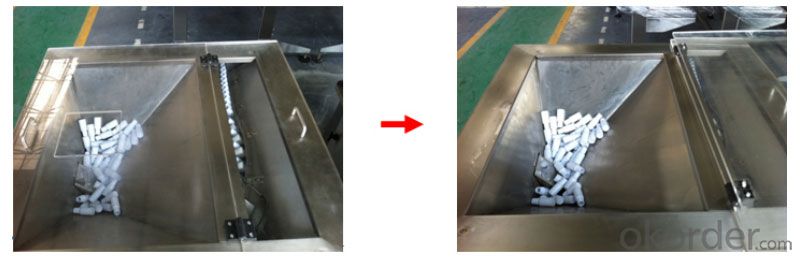

JLP-120 Automatic Bottle Unscrambler is making up of the bottle holder, unscrambling plate and bottle stand. It is applied to the bottle unscrambling of plastic round and flat bottle. When putting the disordered bottle into the bottle holder, through the unscrambling plate, then the bottles will be in the filling line in order. The machine has the features of simple structure, easy operation and good stability.

2、Product Details

JLP-120 Automatic Bottle Unscrambler is making up of the bottle holder, unscrambling plate and bottle stand. It is applied to the bottle unscrambling of plastic round and flat bottle. When putting the disordered bottle into the bottle holder, through the unscrambling plate, then the bottles will be in the filling line in order. The machine has the features of simple structure, easy operation and good stability. It can reduce the labor force. It is your ideal choice for unscrambling the small bottles.

3、Features

3.1 Bottle Holder

3.2 Bottle Unscrambling Structure

Simple structure and easy operation

3.3 Automatic Control

Complete control function, easy operation. It uses frequency converter to control the bottle unscrambling speed.

3.4 Automatic Coordination Function

The machine has the automatic coordination function. When the sensor checks the jam before the filling machine ,the bottle unscrambler will stop. After the jam problem solves, it will restart working.

4、Main Technology Parameter

4.1 Applicable Bottle Size:10-200ml Round, Flat Bottle

4.2 Bottle Diameter:Ø20-40mm

4.3 Capacity:≤120 bottles/hour

4.4 Power:0.5Kw

4.5 Power Source:220V 50Hz

4.6 Amount of Air-consuming : 0.3m³/min

4.7 Weight:350㎏

4.8 External Dimension:900×900×1200(mm)

FAQ

Q1: What is your delivery time?

A: Generally, the delivery time is 45-60 days after receive the deposit, big production line may take more time.

Q2: What is the payment term?

A: We accept both T/T and L/C. Most customers pay by T/T.

Q3: What kind of after-sevices do you provide?

A: If it is not big problem, we can solve it by emails, phone etc. If it can’t work, our engineers can go to overseas to install and adjust the machine and solve the problems.

- Q: What is the charge for packing materials?

- Included in the purchase of goods purchased by the cost, such as material in transit, fixed assets, raw materials and so on, but in the material to the buyer designated place, because the buyer's own reasons again the transport costs included in administrative expenses.

- Q: Paper bags, milk and plastic bags. What's the difference between milk and paper bags?

- The sterilization methods are different......Plastic bags of milk, that is, the use of bus sterilization, is the most do not destroy the milk in the nutrition of the way ~ is also very cheap, in general, buy that kind of milk to drink for a long time ~!The bag is Tetra Pak pillow packaging milk...... with the ultra high temperature sterilization, the sterilization ratio of bus destroys nutrients ~ and will make the lactose coking, to taste, to which + essence, in order to extend shelf life, go inside ~ + preservativeSo, I suggest that we buy plastic packaging milk, cheap and good ~!

- Q: What are the common material choices, printing options and common sense?

- Gift wine gift box: a reference type (single powder cardboard), or gray white cardboard. Larger boxes can be 250+250g mounted, gold card paper and silver cardboard. Different materials should be selected according to the actual needs and grade of the product.Printing: mostly printed in 4C+0 or 4C+1C, and can be printed with spot colors, special gold or silver.After the process: light glue, matte plastic, local UV, matte, hot platinum (metallic film with gold, silver, blue and other colors for choice) or anti-counterfeit film (so that others can not copy), and hit the bump, beer, viscosity and other process.

- Q: How to prevent the use of packaging materials during production without error?

- In addition to training the employees' sense of responsibility, it is most important to identify clearly.1, the regional logo, the specifications are basically the same, but different in nature, placed in different regions.2, the identification of packaging materials.In addition, there is a practical experience for you.

- Q: What is accessory material? What is the difference between it and raw material?

- From this we can see that the auxiliary material is one of the raw materials and belongs to the raw material.For example: to make green pepper fried meat, then oil, salt, sauce, vinegar and other spices are auxiliary materials, and green peppers and meat is the raw material or main material, but they are the raw materials for stir frying.

- Q: What are the categories of packing materials?

- Plastic packing material: PP packing belt, PET packing belt, tearing film, winding film, sealing tape, heat shrinkable film, plastic film and hollow board;

- Q: What are the sales packing materials?

- Packaging in the main plastic bags and corrugated box packaging, corrugated boxes are mainly FOL, TUCK, TOP, BOX and so on; (three) the outer packing is generally used in export cartons, 5 corrugated boxes, corrugated mainly B/C watts. The outer box price calculation formula is: (long + width +8) /100 x (width + high +6) /100 X per square unit price. The length, width and height of the units are CM. For example, the size of an outer box is 60 X, 30 X, 40 CM, and the price is (60+30+8) /100, X (30+40+6), /100, X 6 (market price) = 4.47 yuan.

- Q: What are the commonly used packing materials?

- Metal packaging materials: tin foil hoop steel strapping buckle Blister aluminum PTP aluminum foil steel buckle ceramic glass material wood

- Q: What material or paper should I use for high-grade packaging?!

- The high-end boxes are made into handmade boxesMake India with special paper (in every big Paper Co)If there is a pattern design recommended with pearlescent paper, gold, silver in the process of doing this very good effect.MDF and industrial paperboard are best, MDF strength is better, industrial paperboard flexibility better

- Q: What's the difference between a package and a package?

- Packaging refers to the packaging of products for the storage of various types of containers, such as barrels, boxes, bottles, jars, bags and other materials used for storage and custody of products.Packaging used in the manufacturing process as a component of a product and included in the cost of production at actual cost".

Send your message to us

JLP-120 Automatic Bottle Unscrambler Made In China Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords