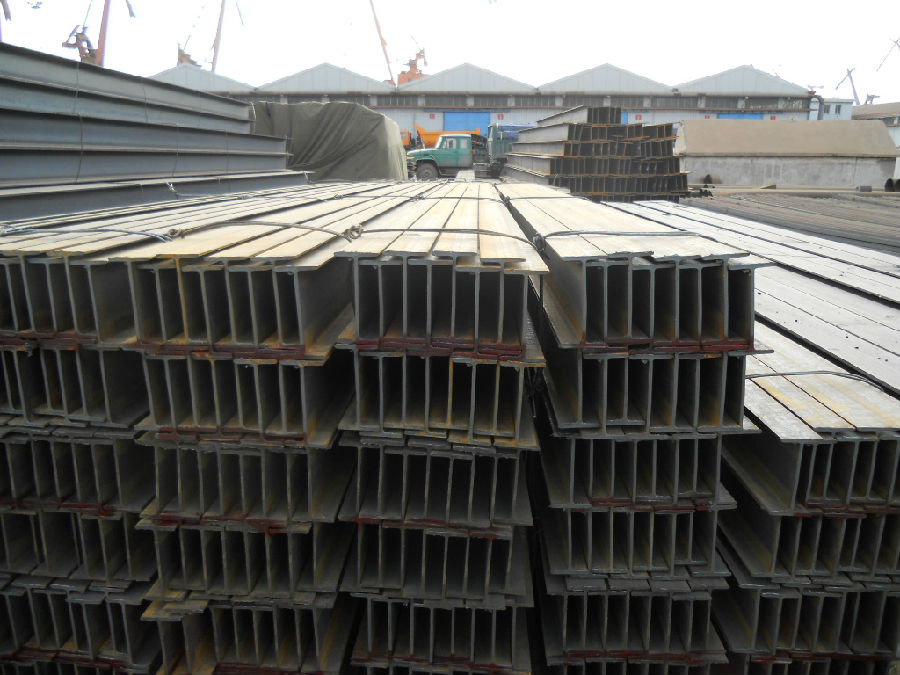

JIS Standard Hot Rolled H-beam Steel Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Structural Steel H-beam JIS Standard at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure. etc.

Product Advantages:

OKorder's Structural Steel H-beam JIS Standard are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

1. Standard: JIS

2. Grade: SS400

3. Length: 12m

4. Invoicing on theoretical weight or actual weight as customer request

5.Payment: TT or L/C

6. Sizes:

H x B

(mm)

| T1 | T2 | JIS Weight

(kg/m)

| GB Weight

(kg/m)

|

100*100 | 6 | 8 | 16.9 | 17.2 |

125*125 | 6.5 | 9 | 23.6 | 23.8 |

150*75 | 5 | 7 | 14 | 14.3 |

148*100 | 6 | 9 | 20.7 | 21.4 |

150*150 | 7 | 10 | 31.1 | 31.9 |

175*90 | 5 | 8 | 18 | 18.2 |

175*175 | 7.5 | 11 | 40.4 | 40.4 |

198*99 | 4.5 | 7 | 17.8 | 18.5 |

200*100 | 5.5 | 8 | 20.9 | 21.7 |

194*150 | 6 | 9 | 29.9 | 31.2 |

200*200 | 8 | 12 | 49.9 | 50.5 |

248*124 | 5 | 8 | 25.1 | 25.8 |

250*125 | 6 | 9 | 29 | 29.7 |

244*175 | 7 | 11 | 43.6 | 44.1 |

250*250 | 9 | 14 | 71.8 | 72.4 |

298*149 | 5.5 | 8 | 32 | 32.6 |

298*201 | 9 | 14 | 65.4 | |

300*150 | 6.5 | 9 | 36.7 | 37.3 |

294*200 | 8 | 12 | 55.8 | 57.3 |

300*300 | 10 | 15 | 93 | 94.5 |

346*174 | 6 | 9 | 41.2 | 41.8 |

350*175 | 7 | 11 | 49.4 | 50 |

340*250 | 9 | 14 | 78.1 | 79.7 |

350*350 | 12 | 19 | 135 | 137 |

400*200 | 8 | 13 | 65.4 | 66 |

390*300 | 10 | 16 | 105 | 107 |

400*400 | 13 | 21 | 172 | 172 |

446*199 | 8 | 12 | 65.1 | 66.7 |

450*200 | 9 | 14 | 77.9 | 79.5 |

440*300 | 11 | 18 | 121 | 124 |

496*199 | 9 | 14 | 77.9 | 79.5 |

500*200 | 10 | 16 | 88.2 | 89.6 |

488*300 | 11 | 18 | 125 | 129 |

596*199 | 10 | 15 | 92.5 | 95.1 |

600*200 | 11 | 17 | 103.4 | 106 |

588*300 | 12 | 20 | 147 | 151 |

700*300 | 13 | 24 | 182 | 185 |

800*300 | 14 | 26 | 207 | 210 |

900*300 | 16 | 28 | 240.1 | 243 |

Usage & Applications of Hot Rolled Steel H-beam For Sale

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure.etc.

Packaging & Delivery of Hot Rolled Steel H-beam For Sale

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

Production flow of Hot Rolled Steel H-beam For Sale

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

- Q: Are steel H-beams resistant to pests or termites?

- Pests and termites pose no threat to steel H-beams due to their high resistance. Unlike wood, which can easily be infested and damaged by insects, steel is an inorganic material that holds no appeal for pests. Termites, specifically, are known to consume cellulose found in wood, but not in steel. Consequently, steel H-beams serve as a robust barrier against infestations by pests and termites, establishing them as a dependable option for providing structural support in buildings and various construction endeavors.

- Q: Can steel H-beams be used for solar panel supports?

- Yes, steel H-beams can be used for solar panel supports. H-beams, also known as I-beams or universal beams, are commonly used in construction due to their strength and durability. They provide excellent structural support and can withstand the weight and wind loads associated with solar panel installations. Steel H-beams also have the advantage of being resistant to corrosion, making them suitable for outdoor applications such as solar panel supports. Additionally, their versatility allows for easy installation and adjustment to accommodate different solar panel sizes and angles. Therefore, steel H-beams are a reliable and widely used choice for supporting solar panels.

- Q: What is the length of the butt joint of H steel? What is the minimum requirement?

- H type steel butt joint is not required for length, but oblique, generally 45 degrees, that is to say, not less than the length of at least H steel height.

- Q: Are Steel H-Beams resistant to UV radiation or fading?

- UV radiation and fading are not things that steel H-beams naturally resist. Carbon steel, the primary material used in constructing steel H-beams, lacks inherent UV resistance. When exposed to UV radiation over time, the steel can undergo oxidation, leading to rust formation and eventual material degradation. To safeguard steel H-beams from UV radiation and fading, manufacturers often use protective coatings like paint or galvanization. These coatings create a barrier between the steel and UV radiation, preventing direct contact and reducing the risk of fading or degradation. However, it's important to note that these protective coatings may require regular maintenance and reapplication to ensure long-term protection against UV radiation. Furthermore, external factors like climate, humidity levels, and the intensity of UV exposure can impact the rate at which steel H-beams fade or degrade due to UV radiation. Regular inspection and maintenance can help detect any signs of fading or degradation in steel H-beams, allowing for timely repairs or replacements to uphold their structural integrity.

- Q: Can steel H-beams be used in theater or stage construction?

- Yes, steel H-beams can be used in theater or stage construction. They are often used as structural elements to provide support and stability for large stages or platforms. Their strong and durable nature makes them suitable for handling heavy loads and ensuring the safety of performers and equipment on stage.

- Q: Can steel H-beams be used in cold climates?

- Yes, steel H-beams can be used in cold climates. Steel is a durable material that can withstand extreme temperatures, including cold weather conditions. H-beams are commonly used in construction projects and are designed to provide structural support, making them suitable for use in various climates, including cold regions.

- Q: Can steel H-beams be used in data center construction?

- Yes, steel H-beams can be used in data center construction. Steel H-beams are commonly used in construction projects due to their strength, durability, and versatility. They provide excellent load-bearing capabilities, making them suitable for supporting heavy equipment and structures in data centers. Additionally, steel H-beams offer a high degree of flexibility in design and can be easily customized to meet specific construction requirements. Their use ensures the stability and longevity of the data center, making them a popular choice in the construction industry.

- Q: Can Steel H-Beams be used in school or educational building construction?

- Indeed, in school or educational building construction, Steel H-Beams find utility. Their strength and durability make them a frequent choice in construction projects. They offer dependable structural support for extensive spans and hefty loads, rendering them appropriate for the construction of educational facilities like schools and universities. These beams serve various functions, such as roof support, open floor plan creation, or the construction of substantial structures like gymnasiums or auditoriums. Moreover, Steel H-Beams can be effortlessly fabricated and installed, thus proving to be cost-effective and efficient in the realm of educational building construction.

- Q: Can steel H-beams be fire-resistant?

- Yes, steel H-beams can be fire-resistant. Steel is inherently fire-resistant as it has a high melting point and does not combust. However, the fire resistance of steel H-beams can be further enhanced by applying fireproof coatings or using intumescent paints. These coatings can provide an additional layer of protection by insulating the steel from the heat of the fire, delaying or preventing its structural failure. Additionally, the design and construction of the building can also play a role in ensuring the fire resistance of steel H-beams, such as implementing fire-rated barriers and compartmentalization to contain the spread of fire. Overall, while steel H-beams are naturally fire-resistant, incorporating additional fire protection measures can further enhance their performance in the event of a fire.

- Q: How do steel H-beams contribute to sustainable building practices?

- Steel H-beams contribute to sustainable building practices in several ways. Firstly, the use of steel as a construction material is highly sustainable due to its durability, recyclability, and long lifespan. H-beams, specifically, are designed to provide structural integrity and support to buildings, allowing for the construction of larger and more sustainable structures. Additionally, the lightweight nature of steel H-beams reduces the overall weight of the building, making it more energy-efficient during transportation and construction. Furthermore, steel H-beams can be prefabricated, reducing on-site waste and construction time. Overall, the use of steel H-beams promotes sustainable building practices by enhancing structural efficiency, reducing waste, and facilitating the use of recyclable materials.

Send your message to us

JIS Standard Hot Rolled H-beam Steel Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords