Hot Rolled JIS Standard H-beam Steel Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Hot Rolled JIS Standard H-beam Steel Bar at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure. etc.

Product Advantages:

OKorder's Hot Rolled JIS Standard H-beam Steel Bar are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Specifications of Hot Rolled Steel H-beam For Sale

1. Standard: JIS

2. Grade: SS400

3. Length: 12m

4. Invoicing on theoretical weight or actual weight as customer request

5.Payment: TT or L/C

6. Sizes:

H x B

(mm)

| T1 | T2 | JIS Weight

(kg/m)

| GB Weight

(kg/m)

|

100*100 | 6 | 8 | 16.9 | 17.2 |

125*125 | 6.5 | 9 | 23.6 | 23.8 |

150*75 | 5 | 7 | 14 | 14.3 |

148*100 | 6 | 9 | 20.7 | 21.4 |

150*150 | 7 | 10 | 31.1 | 31.9 |

175*90 | 5 | 8 | 18 | 18.2 |

175*175 | 7.5 | 11 | 40.4 | 40.4 |

198*99 | 4.5 | 7 | 17.8 | 18.5 |

200*100 | 5.5 | 8 | 20.9 | 21.7 |

194*150 | 6 | 9 | 29.9 | 31.2 |

200*200 | 8 | 12 | 49.9 | 50.5 |

248*124 | 5 | 8 | 25.1 | 25.8 |

250*125 | 6 | 9 | 29 | 29.7 |

244*175 | 7 | 11 | 43.6 | 44.1 |

250*250 | 9 | 14 | 71.8 | 72.4 |

298*149 | 5.5 | 8 | 32 | 32.6 |

298*201 | 9 | 14 | 65.4 | |

300*150 | 6.5 | 9 | 36.7 | 37.3 |

294*200 | 8 | 12 | 55.8 | 57.3 |

300*300 | 10 | 15 | 93 | 94.5 |

346*174 | 6 | 9 | 41.2 | 41.8 |

350*175 | 7 | 11 | 49.4 | 50 |

340*250 | 9 | 14 | 78.1 | 79.7 |

350*350 | 12 | 19 | 135 | 137 |

400*200 | 8 | 13 | 65.4 | 66 |

390*300 | 10 | 16 | 105 | 107 |

400*400 | 13 | 21 | 172 | 172 |

446*199 | 8 | 12 | 65.1 | 66.7 |

450*200 | 9 | 14 | 77.9 | 79.5 |

440*300 | 11 | 18 | 121 | 124 |

496*199 | 9 | 14 | 77.9 | 79.5 |

500*200 | 10 | 16 | 88.2 | 89.6 |

488*300 | 11 | 18 | 125 | 129 |

596*199 | 10 | 15 | 92.5 | 95.1 |

600*200 | 11 | 17 | 103.4 | 106 |

588*300 | 12 | 20 | 147 | 151 |

700*300 | 13 | 24 | 182 | 185 |

800*300 | 14 | 26 | 207 | 210 |

900*300 | 16 | 28 | 240.1 | 243 |

Usage & Applications of Hot Rolled Steel H-beam For Sale

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure.etc.

Packaging & Delivery of Hot Rolled Steel H-beam For Sale

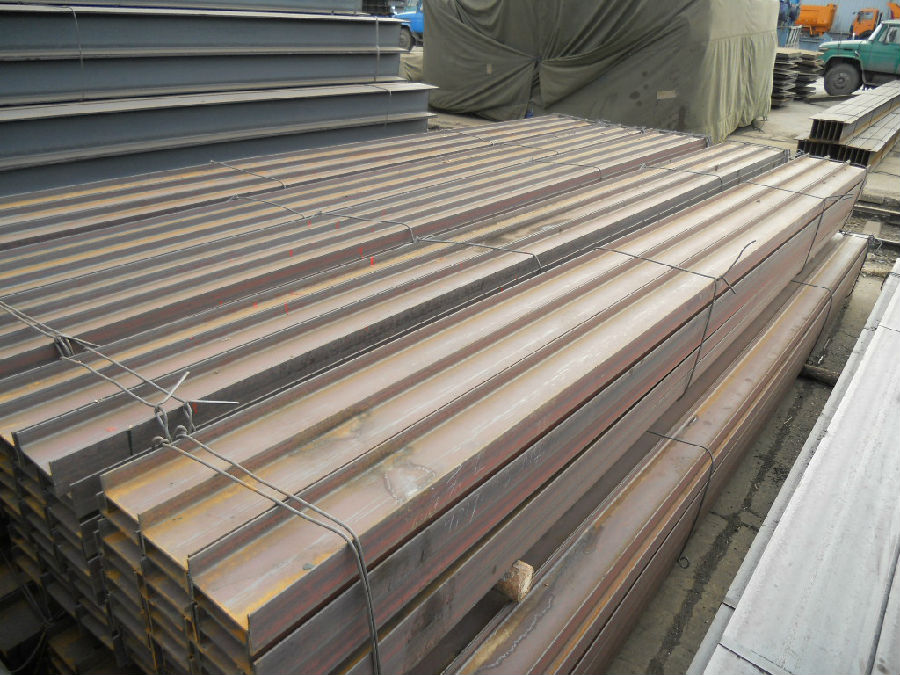

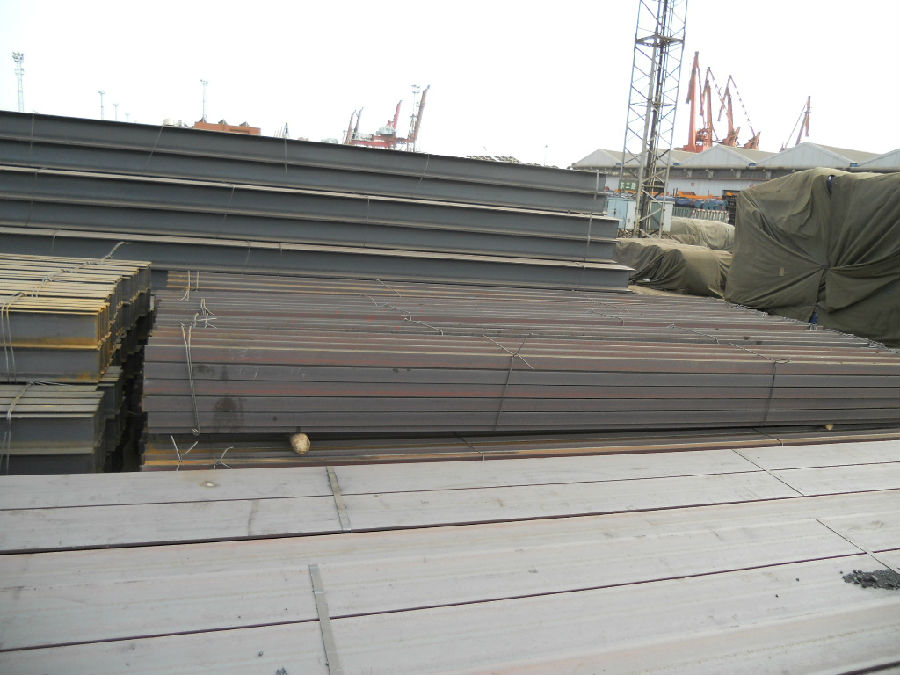

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

- Q: How do steel H-beams contribute to the overall sustainability of a structure?

- Steel H-beams contribute to the overall sustainability of a structure in several ways. Firstly, steel is a highly durable material with a long lifespan, reducing the need for frequent replacements or repairs. This increases the longevity of the structure and minimizes waste generation. Additionally, steel is a recyclable material, meaning that H-beams can be easily repurposed or recycled at the end of their life cycle, reducing environmental impact. Moreover, steel H-beams have a high strength-to-weight ratio, allowing for lighter and more efficient designs, which can result in reduced energy consumption during construction and operation. Overall, the use of steel H-beams promotes sustainable practices by offering durability, recyclability, and energy efficiency in structural design.

- Q: Can steel H-beams be used in the construction of government or municipal buildings?

- Absolutely, government or municipal buildings can certainly utilize steel H-beams in their construction. Due to their exceptional strength, durability, and versatility, steel H-beams are widely employed within the construction industry. They offer excellent structural support and possess the ability to endure heavy loads, rendering them appropriate for a range of building types, including government or municipal buildings. Government or municipal buildings often necessitate expansive open spaces, lengthy spans, and robust structural systems in order to accommodate various functions and activities. Steel H-beams provide the necessary strength and stability to fulfill these requirements. They can be employed as columns, beams, or trusses, thereby creating a resilient framework for the structure of the building. Moreover, steel H-beams boast remarkable flexibility in terms of design and can be easily fabricated to meet specific architectural and structural demands. This empowers architects and engineers to fashion distinctive and visually appealing government or municipal buildings while upholding structural integrity. Additionally, steel H-beams possess numerous advantages over alternative construction materials. They possess fire-resistant and non-combustible properties, and can withstand harsh weather conditions, making them ideal for government or municipal buildings that prioritize safety and durability. In conclusion, steel H-beams represent a practical and efficient choice for the construction of government or municipal buildings. Their strength, durability, design flexibility, and resilience against fire and extreme weather conditions all contribute to their reliability in creating safe and long-lasting structures.

- Q: Are steel H-beams compatible with other construction materials?

- Yes, steel H-beams are compatible with other construction materials. They can be easily integrated with various materials like concrete, wood, or other metals to create sturdy and versatile structures. Steel H-beams are commonly used in construction projects due to their strength, durability, and the ability to support heavy loads.

- Q: Can steel H-beams be used for stadium construction?

- Yes, steel H-beams can be used for stadium construction. H-beams are a common structural element used in construction due to their high strength and versatility. They are capable of supporting heavy loads and providing stability to large structures like stadiums. Additionally, steel H-beams offer several advantages such as durability, fire resistance, and the ability to withstand extreme weather conditions. Their use in stadium construction allows for the creation of large open spaces without the need for intermediate columns, providing unobstructed views for spectators. Overall, steel H-beams are an excellent choice for stadium construction due to their structural integrity and suitability for supporting the unique requirements of such large-scale projects.

- Q: Can steel H-beams be used in solar panel mounting structures?

- Yes, steel H-beams can be used in solar panel mounting structures. Steel H-beams are commonly used in construction due to their strength, durability, and load-bearing capacity. They provide excellent support for solar panels, ensuring stability and resistance to environmental factors such as wind and snow loads. Additionally, steel H-beams can be easily welded or bolted together to create sturdy and reliable structures for solar panel installations.

- Q: Can the section steel butt joint in the end?

- Bolt connection also requires lining plate, pay attention to bolt size, quantity and spacing. To calculate whether thin-walled steel itself will be crushing, the solution is solder paste board, and bolt holes. The principle is that the strength of the butt joint is not weaker than that of other parts, and there is no greater stress.

- Q: Can steel H-beams be used for overhead crane systems?

- Indeed, overhead crane systems can utilize steel H-beams. Owing to their exceptional strength and durability, steel H-beams are frequently employed as the primary structural support for such systems. The H-shaped profile of the beam ensures outstanding load-bearing capacity, enabling it to sustain heavy loads and withstand the dynamic forces encountered during crane operations. Moreover, the assembly and connection of steel H-beams to form the necessary crane structure is a straightforward task. Consequently, steel H-beams are widely favored for overhead crane systems, owing to their reliability and adaptability to demanding applications.

- Q: What are the advantages of using steel H-beams over other types of beams?

- There are several advantages of using steel H-beams over other types of beams. Firstly, steel H-beams offer superior strength and load-bearing capacity, making them suitable for heavy-duty construction projects. Additionally, their shape provides better structural support, allowing for longer spans and reducing the need for additional supporting columns or walls. Steel H-beams also have a high resistance to bending and twisting, ensuring structural stability and durability. Moreover, they are cost-effective due to their availability, ease of fabrication, and recyclability. Lastly, steel H-beams provide design flexibility, enabling architects and engineers to create diverse and innovative structures.

- Q: What are the considerations when designing for sustainable materials in Steel H-Beams?

- When designing for sustainable materials in steel H-beams, several considerations need to be taken into account. Firstly, the choice of raw materials is crucial. Opting for recycled or salvaged steel can significantly reduce the environmental impact of the project. Secondly, the manufacturing process should prioritize energy efficiency and minimize waste generation. Implementing advanced technologies, such as electric arc furnaces, can help achieve these goals. Additionally, the design should aim for optimal structural efficiency to minimize the amount of steel required, thus reducing resource consumption. Lastly, considering the end-of-life phase is essential. Designing for easy disassembly and recyclability ensures that the steel H-beams can be reused or repurposed instead of ending up in landfills. Overall, a holistic approach that encompasses the entire life cycle of the material is necessary to achieve sustainability in steel H-beam design.

- Q: Can steel H-beams be used for column supports?

- Yes, steel H-beams can be used for column supports. They are commonly used in construction due to their high strength and load-bearing capacity, making them suitable for supporting heavy vertical loads in buildings and structures.

Send your message to us

Hot Rolled JIS Standard H-beam Steel Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords