Japanese Standard SS400 H beam with High Quality 482mm-600mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t

- Supply Capability:

- 15000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specifications of Japanese Standard SS400 H beam with High Quality 482mm-600mm:

1. Standard: JIS 3192

2. Grade: SS400 or Equivalent

3. Length: 10m, 12m as following table

4. Invoicing on theoretical weight or actual weight as customer request

5.Payment: TT or L/C

Size and Mass of Japanese Standard SS400 H beam with High Quality 482mm-600mm:

| Size(mm) | Mass (Kg/m) | Size (mm) | Mass (Kg/m) |

| 482*300*11.0 | 111 | 596*199*10.0 | 92.5 |

| 488*300*11.0 | 125 | 600*200*11.0 | 103 |

Packaging & Delivery of Japanese Standard SS400 H beam with High Quality 482mm-600mm for Building Structures:

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel.

Usage of Japanese Standard SS400 H beam with High Quality 482mm-600mm:

(1). for the plant, high-rise building construction

(2). for the bridge, shipment building

(3).for lifting and transportation machinery, equipment manufacturing base building

(4). for the support, foundation pile manufacturing

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The shipping date is dependent upon the quatity, how many sizes you want and the plan of production, but is typically 1 month to 2 months from the beginning of production.

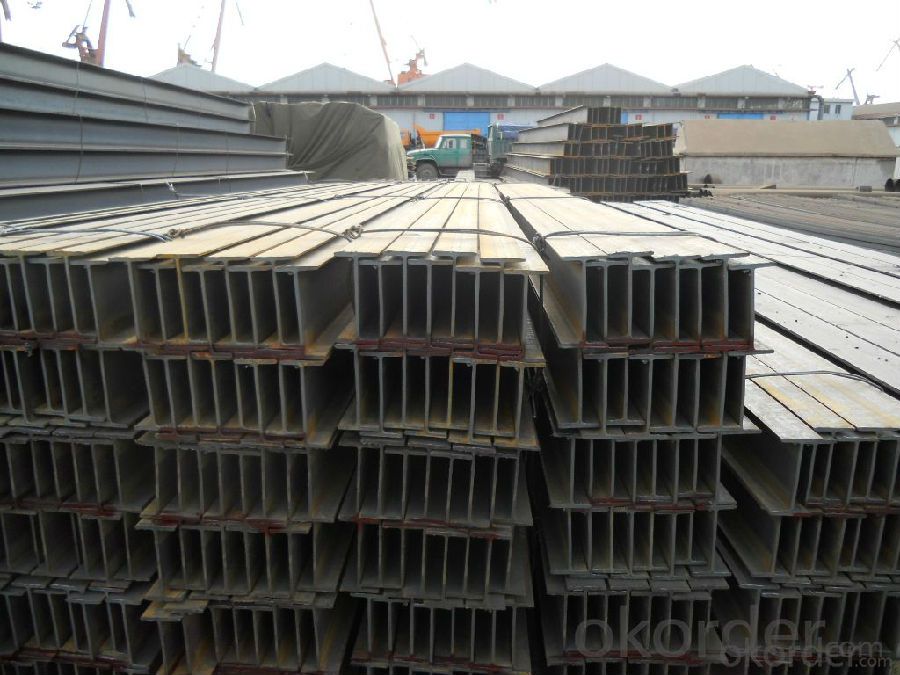

Images of Japanese Standard SS400 H beam with High Quality 482mm-600mm:

* If you would like to get our price, please inform us the size, standard/material and quantity. Thank you very much for your attention.

- Q: How are steel H-beams used in building bridges?

- Steel H-beams are commonly used in building bridges due to their strength and load-bearing capabilities. These beams provide structural support and ensure the stability of the bridge by distributing the weight of the structure evenly. They are typically used as horizontal beams to create the bridge's primary framework, supporting the deck and facilitating the passage of vehicles and pedestrians across the span.

- Q: Are Steel H-Beams suitable for multi-story buildings?

- Indeed, steel H-beams prove to be a fitting choice for constructing multi-story buildings. Frequently referred to as I-beams, H-beams are widely utilized in the field of construction due to their robustness, adaptability, and affordability. The distinctive H shape of these beams allows for remarkable load-bearing capability, thereby enabling the creation of towering and roomy structures. In particular, steel H-beams possess the capacity to bear hefty loads and efficiently transfer them to the foundation, rendering them highly suitable for multi-story buildings. Furthermore, steel as a material exhibits durability by effectively withstanding fire, corrosion, and pests, thereby ensuring the structure's longevity and safety.

- Q: How to control the welding deformation made of H steel

- H steel is a new type of economical construction steel. H type steel cross section shape is reasonable in economy, good mechanical properties, rolling each point on the extended section is uniform, small internal stress, compared with the ordinary beam, a section modulus, light weight, saving advantages of metal, can make the building structure to reduce 30-40%; and because of its inner and outer legs parallel leg end is right, assembled into components, welding, riveting work can save up to 25%. Often used in large capacity requirements, large cross section stability, such as buildings, high-rise buildings, as well as bridges, ships, lifting transport machinery, equipment foundation, support, foundation piles.

- Q: What are the different finishes available for Steel H-Beams, such as galvanized or painted?

- Steel H-Beams come in a variety of finishes, including galvanized and painted options. Galvanized finishes involve coating the steel beam with zinc to prevent corrosion and rust. This makes them ideal for outdoor or high-moisture environments, such as coastal construction projects. Painted finishes, on the other hand, add a decorative touch and act as a protective barrier against rust and corrosion. They can be customized to match specific aesthetic requirements or stand out for safety purposes. Another option is powder coating, which involves applying a dry powder to the steel beam and curing it under heat to create a durable finish resistant to chipping, scratching, and fading. The choice of finish depends on the application and environmental factors. Galvanized finishes are suitable for outdoor or high-moisture environments, painted finishes are versatile and customizable, and powder coating offers durability and attractiveness. Consider the specific needs of your project when selecting the appropriate finish for Steel H-Beams.

- Q: How do steel H-beams contribute to energy-efficient building designs?

- Steel H-beams contribute to energy-efficient building designs due to their high strength-to-weight ratio, which allows for the creation of structurally efficient buildings. The use of H-beams allows for the construction of longer spans and taller buildings, reducing the need for additional support columns and minimizing energy loss. Additionally, their durability and resistance to bending or warping ensure long-term stability, reducing the need for maintenance or replacement.

- Q: What are the different types of steel coatings available for H-beams?

- There are several different types of steel coatings available for H-beams, each with its own unique properties and advantages. 1. Galvanized Coating: This is one of the most commonly used coatings for H-beams. Galvanized coating involves applying a layer of zinc to the surface of the steel through a process called hot-dip galvanizing. This coating provides excellent corrosion resistance, making it ideal for applications where the H-beams are exposed to moisture or harsh environments. 2. Epoxy Coating: Epoxy coatings are frequently used when extra protection against corrosion is required. These coatings consist of a two-part epoxy resin that is applied to the surface of the steel. Epoxy coatings are highly resistant to chemicals, moisture, and abrasion, making them suitable for various industrial applications. 3. Powder Coating: Powder coating involves applying a dry powder to the surface of the H-beams, which is then heated and cured to form a protective layer. This coating provides excellent resistance to scratches, chipping, and fading, making it commonly used in architectural applications where aesthetics are important. 4. Thermal Spray Coating: Thermal spray coatings involve applying a layer of molten or softened material onto the surface of the steel. This process creates a durable coating that provides excellent resistance to corrosion, wear, and high temperatures. Thermal spray coatings are commonly used in industries such as oil and gas, aerospace, and automotive. 5. Organic Coating: Organic coatings, such as acrylic or polyurethane, are often used when a more decorative or aesthetic finish is desired. These coatings provide a high-gloss finish and come in a variety of colors. While they may not offer the same level of corrosion resistance as other coatings, they are still suitable for certain applications where appearance is a primary concern. It is important to consider the specific requirements of your project when choosing a steel coating for H-beams. Factors such as environmental conditions, intended use, and budget will all play a role in determining the most suitable coating option. Consulting with a steel coating expert or engineer can help ensure the best coating is chosen for your specific needs.

- Q: How do steel H-beams perform in terms of shear resistance?

- Steel H-beams perform exceptionally well in terms of shear resistance due to their structural shape and material strength. The H-beams, with their flanges and web, are designed to distribute and resist shear forces effectively. This configuration allows them to withstand heavy loads and lateral forces, making them highly reliable and suitable for applications where shear resistance is critical, such as in construction and engineering projects.

- Q: Can steel H-beams be customized to specific lengths?

- Yes, steel H-beams can be customized to specific lengths. The length of steel H-beams can be altered during the manufacturing process to meet the specific requirements of construction projects.

- Q: Are steel H-beams susceptible to fatigue?

- Yes, steel H-beams are susceptible to fatigue. Fatigue is the weakening and failure of a material due to repeated stress cycles. Steel H-beams, like any other structural components, can experience fatigue if they are subjected to repeated or fluctuating loads over time. The repeated stress cycles can lead to the initiation and propagation of cracks in the material, ultimately resulting in failure. Factors such as the magnitude, frequency, and duration of the applied loads, as well as the quality and condition of the steel, can influence the susceptibility to fatigue. To prevent fatigue failure, engineers and designers must carefully consider the expected loads and apply appropriate design criteria, such as incorporating safety factors, conducting fatigue analysis, and implementing proper maintenance and inspection programs.

- Q: Are steel H-beams suitable for manufacturing plants?

- Yes, steel H-beams are suitable for manufacturing plants. Steel H-beams are commonly used in construction and engineering projects due to their structural strength and stability. They have a high load-bearing capacity, making them ideal for supporting heavy machinery and equipment in manufacturing plants. H-beams are also versatile and can be easily customized to meet specific design requirements. Additionally, steel is a durable and long-lasting material that can withstand harsh industrial environments, making it a reliable choice for manufacturing plant structures.

Send your message to us

Japanese Standard SS400 H beam with High Quality 482mm-600mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t

- Supply Capability:

- 15000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords