HSLJ High Speed Bag-on-roll Making Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We have a large-scale, independent research and development and sales of specialty plastic packaging machinery.

The company mainly produces bag making machine, glove machine, film blowing machines, printing presses, granulators and so full of plastic packaging machinery and equipment, products exported to South America, North America, Southeast Asia, Middle East, Africa, Scandinavia and other countries, much favored by the market and praised by users.

NO: 2014714112150

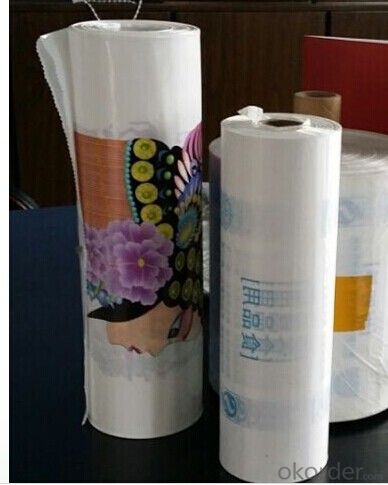

Name: HSLJ-450X2 Double-line High Speed Bag-on-roll Making Machine

1 this machine for the production (with printed or blank) rolling bag design, can produce octagonal bags, garbage bags, fruit and vegetable bags and tablecloths bags.

2 using two servo motors and four variable frequency motor synchronous operation, to ensure stable operation speed and bag. 4 PEC correction device to ensure smooth rewinding.

3 points off the seal in the same position, no tension design.

4 can handle 0.005-0.05mm thickness high density polyethylene (HDPE) and low density polyethylene (LDPE) material film.

NO: 201487163749

Name: T-shirt Bag on Roll Making Machine HSR-500/600700/800

Machine Data:

Model | HSR-500 | HSR-600 | HSR-700 | HSR-800 |

Max. Bag Width | 450mm | 550mm | 650mm | 750mm |

Max. Bag Length | 1200mm | 1200mm | 1200mm | 1200mm |

Film thickness | 0.008-0.10mm | 0.008-0.10mm | 0.008-0.10mm | 0.008-0.10mm |

Bag Making Speed | 40-120pcs/min | 40-120pcs/min | 40-120pcs/min | 40-120pcs/min |

Main Power | 1.1kw | 1.1kw | 1.5kw | 1.5kw |

Machine Dimension | 3.3*1.1*1.5m | 3.3*1.2*1.5m | 3.3*1.3*1.5m | 3.3*1.4*1.5m |

Machine Weight | 850kg | 900kg | 1000kg | 1800kg |

- Q: Where is secondhand corrugated paper packaging machinery available?

- Carton factory and general production enterprise is different,General business is to face direct consumers, the need for their own sales network, sales staff, sales means......And carton factory as long as accurate manufacturers, show their means, get business.Maybe you walked into a food factory, an electrical factory, a furniture factory, a toy factory...... Can be your client.With business, but also to choose their own plant.Cartons are flammable and afraid of water. This is the disadvantage of cartons. If handled properly, there will be no problem.Site is best to avoid low-lying and rainy lots of water, the cardboard should not be piled directly on the ground, the bracket is a good choice.No smoking in the factory area, no open fire, and good fire fighting equipment, so as to ensure the safety of production.The size of the initial plant is best to be 500 square meters, or larger, smaller.

- Q: What is the design basis of automated packaging?! Just for today!

- Greatly improve the degree of automation of process flowA few years ago, automation technology accounted for only 30% of the design of packaging machinery, now has accounted for more than 50%, a large number of micro computer design and mechanical and electrical integration control. To improve the packaging machinery automation, one is to increase productivity; the two is to improve the flexibility and agility equipment; three is to improve the ability of packaging machinery to complete the complex action, namely the manipulator to complete the packaging process. Such as chocolate packaging has been achieved, with mechanical hand instead of the original manual. Automatic design of packaging machinery has the following two main characteristics:

- Q: The difference between wrapping and bagging is explained from the packaging method, and the difference of the working principle of the packaging machine is analyzed

- A small object, small particle, powder, crystal, liquid, suitable for packing

- Q: Ask a mechanical problem, the waste film recycling in the packaging machinery is a new film packaging, after cutting, then use the roller to recycle the waste film. Encounter a

- Is it settled?. Not really! It is not recommended to use torque as parameter control here. This is a tricky amount of control. And easy to fluctuate, prone to misoperation

- Q: What machine does the packing carton machine have?

- Do the carton machinery: corrugated production line / single machine, printing machine, polishing machine, laminating machine, mounting machine, die-cutting machine, book paste machine for package machinery: automatic sealing machine, automatic strapping machine

- Q: Working principle of packing machine

- Then, by heating the sealing part of the bag bottom sealing, again is material, the material into the packaging machine, and then sealing, finally cut off, a complete package came out, this is the working principle of small vertical packaging machine.

- Q: Which friend is an expert in mechanical equipment or a better understanding of sealing machines? Tell me how to identify the equipment

- If these are good, and then talk about the price, always a penny goods, this side, quick packaging machine is not bad,

- Q: What are the structures of the packaging machinery?

- Is a company engaged in outsourcing clients, packaging, processing, packaging equipment, leasing, services, sales in one of the specialized companiesSales of second-hand packing equipment according to the customer's product features and requirements. Reduce customer purchasing costsAccording to the customer's product characteristics and requirements. Select the best packaging equipment for customers, reduce customer purchasing costsPackaging equipment spare parts sales and maintenance services

- Q: Energy saving reform of packaging machine

- A) the main control circuit is composed of man-machine interface (text display), frequency converter and programmable logic controller (PLC), which constitute the control core;B) the temperature control circuit is composed of an intelligent temperature control meter, a solid state relay and a thermocouple element. The temperature control is accurate, the display is intuitive, and the setting is convenient;C) multi point tracking and detection by photoelectric switches and electromagnetic proximity sensors; 2) fully automatic pillow type working principle:With the improvement of automation, the operation, maintenance and routine maintenance of the packing machine are more convenient and simple, and the professional skill requirements of the operators are reduced. The quality of the product packaging is directly related to the temperature system, the speed accuracy of the main engine and the stability of the tracking system.

- Q: Will the Internet be too passive? Telephone marketing, what kind of food can be found in the factory, such as the phone, people basically do not need, and all have. Does the salesman run the market? How do you run? Thanks for the direction...

- Mechanical sales are nothing more than two points: first, equipment aging, need to update; two, equipment efficiency is low, need to improve. You don't know anything about the customer. Come up and sell the product. If you are a customer, I don't think you have the patience to listen

Send your message to us

HSLJ High Speed Bag-on-roll Making Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords