Hot Selling H Beam Profile to Africa Market

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Standard: GB700-88, Q235B2.

2. Grade: Q235, SS400 or Equivalent

3. Length: 6m,10m, 12m as following table

4. Invoicing on theoretical weight or actual weight as customer request

5.Payment: TT or L/C

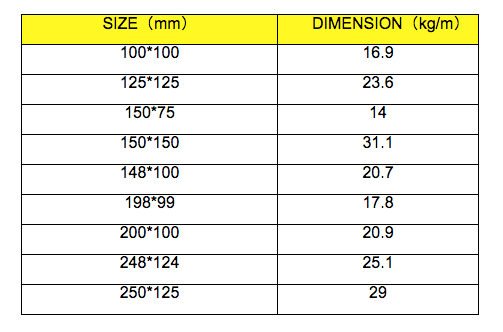

6. Sizes:

Usage & Applications of Hot Rolled Structural Steel H Beam

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure. etc.

Packaging & Delivery of Hot Rolled Structural Steel H Beam

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: Can fit in the containers of 20fts the steel beams of 6M?

A2: No proble, we can put them into the containers in the form sideling.

Q3: The products are invoicing on theoritical weight or on actual weight?

A3: We can do it in both manners, according to the customers' request.

- Q: Can steel H-beams be used in the construction of sports arenas?

- Sports arenas can indeed utilize steel H-beams for construction purposes. These H-beams possess numerous benefits that render them suitable for this particular type of edifice. First and foremost, H-beams boast exceptional strength and durability, enabling them to bear the immense weight of expansive roof structures, seating areas, and other substantial loads commonly found in sports arenas. Moreover, steel H-beams exhibit a high resistance to corrosion, which proves essential in structures that are constantly exposed to diverse weather conditions. Furthermore, the versatility of steel permits the fabrication of H-beams in various sizes and shapes, guaranteeing that they can be customized to meet the precise design requirements of sports arenas. In conclusion, the utilization of steel H-beams in the construction of sports arenas ensures the creation of a secure and sturdy structure that can withstand the demands of accommodating large crowds and supporting intricate roof systems.

- Q: Can steel H-beams be used in the construction of theaters or auditoriums?

- Certainly! Steel H-beams have proven to be a valuable asset in the construction of theaters and auditoriums. Their strength and durability make them a popular choice in the industry. These beams offer structural support and are frequently utilized as load-bearing components in various building projects. In the case of theaters and auditoriums, where expansive open spaces and lofty ceilings are often desired, steel H-beams can be employed to establish the necessary framework and provide support for the structure. Furthermore, these beams can be easily fabricated and tailored to meet the specific design and structural prerequisites of the theater or auditorium. Overall, steel H-beams are widely favored in the construction field due to their robustness, versatility, and dependability - qualities that make them particularly suitable for the construction of theaters and auditoriums.

- Q: Can steel H-beams be used for industrial storage facilities?

- Yes, steel H-beams can be used for industrial storage facilities. Steel H-beams are commonly used in construction due to their strength and load-bearing capabilities. They provide structural support and can withstand heavy loads, making them suitable for industrial storage facilities where large quantities of materials or products need to be stored. Additionally, steel H-beams are durable and resistant to weathering, ensuring the longevity of the storage facility. They also offer versatility in terms of design and layout possibilities, allowing for efficient use of space and customization to meet specific storage needs. Overall, steel H-beams are a reliable and practical choice for constructing industrial storage facilities.

- Q: Are there any limitations on the length of steel H-beams?

- Yes, there are limitations on the length of steel H-beams. The length of H-beams is typically limited by the manufacturing capabilities and transportation logistics. In terms of manufacturing, the size and weight of the H-beam can affect the length that can be produced. Larger and longer H-beams may require specialized manufacturing equipment and processes, which may not be readily available. Transportation logistics also play a role in the length limitation. H-beams are typically transported by truck or rail, and there are restrictions on the maximum length that can be transported without obtaining special permits. These restrictions are imposed by local regulations and transportation authorities to ensure safe and efficient transportation. In addition, longer H-beams may be more prone to bending or warping during handling and installation, which can affect their structural integrity. Therefore, there may be practical limitations on the length of steel H-beams based on these considerations. It is important for architects, engineers, and manufacturers to assess the specific project requirements and limitations when determining the appropriate length of steel H-beams to ensure safety, efficiency, and compliance with regulations.

- Q: Are steel H-beams compatible with different construction materials?

- Indeed, steel H-beams exhibit compatibility with diverse construction materials. Owing to their adaptability and robustness, steel H-beams find utility in an extensive array of construction undertakings, harmonizing effortlessly with an assortment of substances such as concrete, wood, and masonry. They can be incorporated as integral support components within building frameworks, bridges, and other infrastructure ventures. The capacity of steel H-beams to endure substantial burdens and furnish stability renders them a favored selection for amalgamating with varying construction materials across numerous applications.

- Q: Can steel H-beams be used for retaining walls?

- Yes, steel H-beams can be used for retaining walls. Steel H-beams are often used in construction projects for their strength and durability. They are capable of withstanding heavy loads and can provide excellent support for retaining walls. The H-shape of the beam allows for better weight distribution and stability, making it a suitable choice for retaining walls that need to withstand pressure from soil or other materials. Additionally, steel H-beams can be easily installed and offer a long lifespan, making them a popular choice for various construction applications, including retaining walls.

- Q: How do steel H-beams contribute to the overall cost-effectiveness of a project?

- Steel H-beams contribute to the overall cost-effectiveness of a project by providing a strong and durable structural support system. Their high strength-to-weight ratio allows for the use of fewer materials, reducing construction costs. Additionally, their versatility and ease of installation result in reduced labor expenses. Moreover, steel H-beams require minimal maintenance and have a longer lifespan, resulting in long-term cost savings.

- Q: Can Steel H-Beams be used for supporting heavy machinery or equipment?

- Yes, Steel H-Beams can be used for supporting heavy machinery or equipment. Steel H-Beams are designed to provide structural support and are commonly used in construction and industrial applications. They have high strength and durability, making them suitable for bearing heavy loads. H-Beams are often used in the construction of bridges, buildings, and other structures that require substantial support. Additionally, their wide flanges and strong web enable them to distribute weight evenly, making them ideal for supporting heavy machinery or equipment. However, it is essential to consider the specific weight and load-bearing requirements of the machinery or equipment in question and consult with a structural engineer to ensure that the chosen H-Beam is appropriate for the intended application.

- Q: What is the fire rating of steel H-beams?

- The fire rating of steel H-beams typically depends on various factors such as the size and thickness of the beam, the type and thickness of any fire-resistant coatings or treatments applied to the beam, and the overall fire protection system in place. Generally, steel is considered to have inherent fire-resistant properties compared to other building materials such as wood. However, without additional fire protection measures, steel H-beams can lose their load-bearing capacity in high temperatures due to thermal expansion and structural deformation. To improve the fire resistance of steel H-beams, fire protection measures can be implemented, including fire-resistant coatings or fireproofing materials that are applied to the surface of the beams. These coatings or materials are designed to provide a certain level of fire resistance by retarding the heat transfer and delaying the point at which the steel reaches its critical temperature. The fire rating assigned to steel H-beams will depend on the specific fire protection measures employed. Fire ratings are typically expressed in terms of time, such as 30 minutes, 60 minutes, 90 minutes, or 120 minutes, indicating the duration for which the steel beams can withstand fire exposure without significant loss of structural integrity or load-bearing capacity. It is essential to consult with fire protection engineers, architects, and relevant building codes or standards to determine the appropriate fire rating for steel H-beams in a specific application.

- Q: What are the different types of steel H-beam connections used in industrial buildings?

- Industrial buildings commonly use several different types of steel H-beam connections to ensure stability and support for the overall structure. Below are some of the most frequently utilized connection types: 1. Welded connection: The prevalent connection type in industrial buildings involves welding the H-beam to other structural members or plates. Welded connections offer exceptional strength and rigidity, making them suitable for heavy-duty applications. 2. Bolted connection: In bolted connections, the H-beam is secured to other structural members using bolts and nuts. This connection type allows for convenient disassembly and reassembly, making it ideal for buildings that may require modification or relocation in the future. 3. Pinned connection: Pinned connections permit rotation at the joint, adding flexibility to the structure. This connection type is commonly employed in situations that necessitate accommodating movement or vibration, such as bridges or buildings located in earthquake-prone areas. 4. Moment connection: Moment connections are designed to transfer both vertical and horizontal forces between the H-beams and other structural members. These connections provide enhanced stability and resistance against bending moments, making them suitable for structures with high loads or complex geometries. 5. Shear connection: Shear connections are utilized to transfer shear forces between the H-beams and other structural members. These connections are typically designed to resist lateral loads and provide stability to the structure. Various factors, including load requirements, structural design, and construction method, influence the choice of H-beam connection type. Engineers and designers evaluate these factors to determine the most suitable connection type for each specific application.

Send your message to us

Hot Selling H Beam Profile to Africa Market

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords