Hot Selling H Beam Profile with Grade A Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Standard: GB700-88, Q235B2.

2. Grade: Q235, SS400 or Equivalent

3. Length: 6m,10m, 12m as following table

4. Invoicing on theoretical weight or actual weight as customer request

5.Payment: TT or L/C

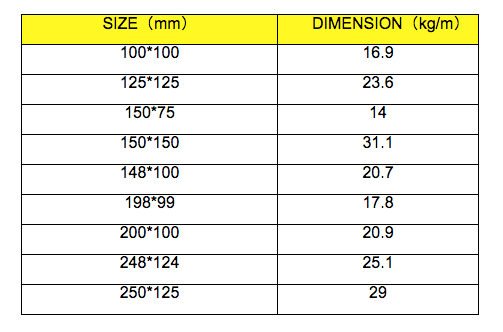

6. Sizes:

Usage & Applications of Hot Rolled Structural Steel H Beam

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure. etc.

Packaging & Delivery of Hot Rolled Structural Steel H Beam

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: Can fit in the containers of 20fts the steel beams of 6M?

A2: No proble, we can put them into the containers in the form sideling.

Q3: The products are invoicing on theoritical weight or on actual weight?

A3: We can do it in both manners, according to the customers' request.

- Q:Can steel H-beams be used in the construction of educational institutions?

- Indeed, educational institutions can utilize steel H-beams for their construction purposes. The reason behind their widespread usage in the construction industry lies in their tremendous strength, durability, and versatility. These beams possess exceptional load-bearing capabilities and are capable of supporting heavy structures. Consequently, they are an ideal choice for educational buildings that typically necessitate spacious interiors and lofty ceilings. Steel H-beams can be employed to construct the fundamental framework of the building, encompassing columns, beams, and roof structures. Moreover, steel is an environmentally sustainable material, given its ability to be recycled and reused. As a result, it serves as an eco-friendly option for educational institutions. All in all, steel H-beams are a fitting and frequently employed choice when it comes to constructing educational institutions.

- Q:Are there any health concerns associated with Steel H-Beams?

- Steel H-Beams can potentially raise health concerns due to their composition. Typically made from carbon steel, which contains trace amounts of lead, chromium, and nickel, these elements can pose health risks if they are released into the environment or individuals come into direct contact with them. One issue to consider is lead poisoning, a serious health condition caused by exposure to this toxic heavy metal. Particularly harmful to children, if lead is present in steel beams and released into the air or water, it can contaminate the surrounding environment and endanger human health. Another worry involves the presence of chromium and nickel. These metals can trigger allergic reactions and skin irritation in sensitive individuals. Direct contact with steel beams containing these elements can result in dermatitis or other skin conditions. Additionally, the production and processing of steel involve the use of various chemicals and substances that can be harmful if not handled and disposed of properly. For instance, the welding process used to fabricate steel beams may release toxic fumes like zinc oxide or manganese, which can negatively impact respiratory health if inhaled. It is crucial to emphasize that the health risks associated with Steel H-Beams can be minimized by following appropriate handling, storage, and disposal practices. Employers and workers who come into contact with steel beams should receive education about potential health hazards and take necessary precautions to safeguard themselves. Furthermore, strict adherence to environmental regulations and safety standards is essential to ensure that steel production processes do not pose any risk to human health or the environment.

- Q:Is the beam made of I-beam or H?

- The I-shaped and H type are actually the same shape, which refers to the appearance of the formed steel beam, usually called the H type steel beam.

- Q:How do steel H-beams perform in seismic zones?

- Steel H-beams perform exceptionally well in seismic zones due to their inherent strength and flexibility. The design of H-beams allows them to resist lateral forces and vibrations caused by earthquakes, ensuring structural stability and minimizing damage.

- Q:How do steel H-beams perform in terms of torsion resistance?

- Steel H-beams have excellent torsion resistance due to their shape and design. The horizontal flanges and vertical web provide high strength and stability against twisting forces, making them ideal for applications requiring resistance to torsion.

- Q:Can steel H-beams be used for supporting airport hangars?

- Yes, steel H-beams can be used for supporting airport hangars. Steel H-beams are commonly used in construction due to their strength and durability, making them suitable for supporting large structures like airport hangars.

- Q:Can steel H-beams be used for agricultural buildings?

- Yes, steel H-beams can be used for agricultural buildings. Steel H-beams are commonly used in construction due to their strength, durability, and cost-effectiveness. They provide structural support and can withstand various weather conditions, making them suitable for agricultural buildings such as barns, storage facilities, or equipment sheds.

- Q:What are the different types of steel H-beam connections used in residential buildings?

- There are several types of steel H-beam connections commonly used in residential buildings, including bolted connections, welded connections, and moment resisting connections. Bolted connections involve using bolts and nuts to connect the beams together, providing flexibility for future adjustments or modifications. Welded connections use heat and metal filler to fuse the beams together, creating a strong and permanent connection. Moment resisting connections are designed to resist lateral forces and moments, often achieved through the use of additional plates, bolts, and welds. The choice of connection type depends on factors such as structural requirements, cost, and ease of installation.

- Q:How do steel H-beams resist bending and twisting forces?

- Steel H-beams are specifically designed to resist bending and twisting forces due to their unique shape and material properties. The H shape of the beam provides a significant advantage in terms of structural strength and stability. The top and bottom flanges of the H-beam are thicker and wider than the web, which creates a larger surface area to distribute forces. This increased surface area helps to resist bending forces as it can handle more load and distribute it over a larger area. Moreover, the flanges are oriented perpendicular to the web, which further enhances their resistance to bending. In addition to the shape, the material properties of steel contribute to the beam's ability to resist bending and twisting forces. Steel is known for its high strength and stiffness, making it an ideal choice for structural applications. The combination of its strength and ductility allows steel H-beams to withstand considerable loads without permanent deformation. Furthermore, the design of H-beams allows them to efficiently transfer loads and resist twisting forces. The flanges and web work together to create a rigid structure that resists twisting or torsional forces. The web connects the flanges and provides stability, preventing the beam from twisting under applied loads. Overall, the unique shape and material properties of steel H-beams make them highly resistant to bending and twisting forces. Their ability to distribute loads, withstand bending moments, and resist torsional forces makes them a popular choice in various structural applications, such as building frames, bridges, and other load-bearing structures.

- Q:Are steel H-beams resistant to corrosion or rust?

- Yes, steel H-beams are resistant to corrosion or rust. Steel beams are commonly made from high-strength carbon steel, which has excellent corrosion resistance properties. These beams are often coated with protective substances like paint or galvanized coatings to further enhance their resistance to corrosion. The protective coatings act as a barrier between the steel and the surrounding environment, preventing the formation of rust or corrosion. This makes steel H-beams highly durable and suitable for applications in various industries, including construction, engineering, and infrastructure projects.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Selling H Beam Profile with Grade A Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords