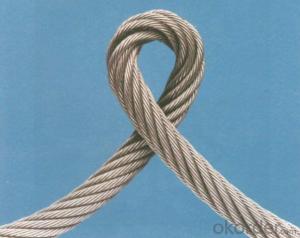

Hot sale types of steel wire rope 1*7 1*19 7*19

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Steel Grade: steel wire rope

Standard: AISI, ASTM, BS, DIN, GB, JIS

- Type: Galvanized

Application: Construction

Alloy Or Not: Non-alloy

Packaging & Delivery

| Packaging Details: | in coil or as per your request |

|---|---|

| Delivery Detail: | 10-20days after confirm the order |

Specifications

Hot sale types of steel wire rope

1.size: 6*7 6*19 6*37 7*19 1*19

2.Standard : DIN ,BS, EN12385-4

3.Top quality ang best pric

Good quality steel wire rope, Hot sale types of steel wire rope 1*7 1*19 7*19

Welcome OEM order and inquiry.

1) standard:GB/T20118-2006,DIN,JIS and etc

2) construction: 1*19,6*19,7*19,6*7,7*7,6*12+7FC,6*37,6*24+7FC

3) diameter(mm):1.5mm-60mm

4) nominal tensile strength(Mpa):1570 1670 1770 1870 1960 2060

5) main application: verious equipment for derricking,elevator, lifting and drawing.

6) quality control: ABS,ISO9001,ISO14001

Specification of wire rope

STEEL WIRE ROPE | |||

Construction | Diameter | Type | Usage |

1*7 | 0.5~16mm | Steel wire rope | Marine |

1*12 | 1.0~30mm | General purpose wire rope | Running Rigging |

1*19 | 1.0~30mm | PVC wire rope | Fishing |

4*31 | 8.3mm | hot-dipped galvanized | Crane |

6*7 | 0.8~18mm | Galvanized steel wire rope | Hoist |

7*7 | 0.8~18mm | Wire rope sling | Oil Drilling |

6*12+7FC | 2~40mm | Elevator wire rope | General Engineering purpose |

6*19+FC(IWR) | 2.0~60mm | Stainless steel wire rope | Automobile Control cable,Ocean, Construction,Aircraft,Decoration ,etc |

6*19+FC(IWRC) | 3.0~60mm |

| |

6*24+7FC | 8.0~40mm | ||

6*37+FC(IWR, IWRC) | 6.0~120mm | ||

6*36 | 6.0~120mm | ||

8*19S+FC | 6~16mm | ||

8*19w+FC (IWR) | 6~16mm | ||

6*25Fi+FC | 6~35mm | ||

18*7+FC | 3~36mm | ||

34*7+FC(IWR, IWS) | |||

- Q: How are steel wire rods used in the production of tire cords?

- Steel wire rods are commonly used in the production of tire cords as they provide essential strength and durability. The tire cords are essentially the reinforcement material embedded within the rubber of a tire, which helps to improve its structural integrity and resistance to wear and tear. To manufacture tire cords, steel wire rods undergo a series of processes. First, the rods are drawn through a die to reduce their diameter and increase their length. This process, known as wire drawing, helps to improve the tensile strength and flexibility of the steel wires. After wire drawing, the steel wire rods are further processed through a series of heat treatment methods to enhance their mechanical properties. This includes processes such as annealing, quenching, and tempering. These treatments help to improve the wire's strength, elasticity, and resistance to fatigue, making them suitable for the demanding conditions in which tires operate. Once the steel wire rods have been properly treated, they are then twisted or braided together to form the tire cords. These cords are typically arranged in a crisscross pattern, known as the bias angle, to provide optimal strength and stability to the tire. The cords are then embedded within the rubber layers during the tire manufacturing process. The presence of steel wire cords in tires ensures that they can withstand the forces exerted during vehicle operation, including cornering, acceleration, and braking. The cords help to distribute the load evenly across the tire, improving its handling, stability, and overall performance. Additionally, the steel cords also contribute to the puncture resistance and longevity of the tires, making them more reliable and durable. In summary, steel wire rods are essential in the production of tire cords, providing strength, durability, and resilience to the tires. Through various processes such as wire drawing, heat treatment, and twisting or braiding, steel wire rods are transformed into tire cords that enhance the structural integrity and performance of tires in a wide range of driving conditions.

- Q: What are the common applications of low carbon and oil tempered steel wire rod?

- Due to their unique properties, low carbon and oil tempered steel wire rod find a wide range of applications. These types of steel wire rod are commonly utilized in the following areas: 1. Springs: The automotive industry extensively utilizes low carbon and oil tempered steel wire rod in the production of springs. These springs require high tensile strength, excellent resistance to fatigue, and good flexibility, all of which are provided by these steel wire rods. 2. Wire ropes: Various industries, such as mining, construction, and transportation, rely on low carbon and oil tempered steel wire rod for the production of wire ropes. These steel wire rods possess high tensile strength and durability, making them suitable for withstanding heavy loads and harsh conditions. 3. Fasteners: Low carbon and oil tempered steel wire rod are commonly employed in the manufacturing of fasteners like bolts, nuts, and screws. These steel wire rods offer the necessary strength and toughness required for fasteners to withstand high loads and prevent failure. 4. Wire meshes: In industries such as agriculture, construction, and filtration, low carbon and oil tempered steel wire rod are utilized in the production of wire meshes. These steel wire rods exhibit excellent corrosion resistance and structural stability, making them ideal for applications where strength and durability are crucial. 5. Automotive components: Low carbon and oil tempered steel wire rod are utilized in the production of various automotive components, including seat frames, suspension systems, and brake springs. These steel wire rods provide the required strength, flexibility, and resistance to wear, ensuring the safety and performance of these automotive parts. Overall, low carbon and oil tempered steel wire rod have diverse applications across industries such as automotive, construction, mining, and manufacturing. These applications necessitate strength, durability, and flexibility.

- Q: How is steel wire rod used in the manufacturing of fencing?

- Steel wire rod is commonly used in the manufacturing of fencing as it serves as the primary material for producing sturdy and durable fencing wires. The wire rod is first drawn through a series of dies to attain the desired thickness and strength. These wires are then woven or welded together to form the fencing structure, providing security, containment, and boundary demarcation in various applications such as residential, commercial, agricultural, and industrial settings.

- Q: How is steel wire rod stored and handled to prevent damage?

- Steel wire rod is typically stored and handled with utmost care to prevent any damage. It is usually stored in a well-organized manner, with proper spacing between the rods to avoid tangling or entanglement. Additionally, the rods are often stored in a dry and covered area to protect them from moisture and corrosion. When handling steel wire rod, workers use appropriate lifting equipment that ensures a secure grip without causing any bending or distortion. By following these precautions, the risk of damage to the steel wire rod is minimized, ensuring its quality and integrity.

- Q: What are the common production processes for plutonium-coated steel wire rod?

- The common production processes for plutonium-coated steel wire rod typically include several steps. Firstly, the steel wire rod is cleaned and prepared to remove any impurities or contaminants. This is followed by a process called electroplating, where a layer of plutonium is deposited onto the surface of the steel wire rod. The electroplating process involves immersing the wire rod into a solution containing plutonium ions and passing an electric current through it, causing the plutonium to adhere to the surface. After the electroplating, the wire rod is usually subjected to a curing process to ensure the plutonium coating is firmly bonded to the steel. Finally, the coated wire rod is inspected for quality control purposes to ensure it meets the required specifications before it can be used in various applications.

- Q: How are steel wire rods used in the production of wire cables for transmitting signals?

- Steel wire rods are essential components in the production of wire cables used for transmitting signals. These rods are initially manufactured by hot rolling billets of low carbon steel into long, thin shapes. This process ensures that the steel wire rods have the necessary strength and flexibility required for their application in wire cable production. Once the steel wire rods are obtained, they undergo various steps to transform them into wire cables capable of transmitting signals. The first step involves cleaning and coating the rods to prevent corrosion and improve their durability. This coating can be made of zinc, copper, or other materials depending on the specific requirements of the cable. After the rods are coated, they are then drawn through a series of dies to decrease their diameter and increase their length. This drawing process further enhances the strength and flexibility of the rods, making them suitable for the demanding conditions that wire cables may encounter during installation and use. The drawn steel wire rods are then twisted or braided together to form the core of the wire cable. This core provides the necessary mechanical strength and stability for the cable, allowing it to withstand tension and external forces. The number of rods used in the core can vary depending on the desired strength and thickness of the cable. To ensure efficient signal transmission, the core is covered with an insulating material, typically made of plastic or rubber. This insulation protects the core from damage, prevents electrical interference, and maintains the integrity of the signal being transmitted. Finally, the completed wire cables are tested to ensure their quality and performance. They are inspected for any defects or imperfections that could affect their ability to transmit signals effectively. Once approved, these cables are ready to be used in various applications, such as telecommunications, electrical systems, and data transmission. In summary, steel wire rods play a crucial role in the production of wire cables used for transmitting signals. They provide the necessary strength, flexibility, and durability to withstand the demanding conditions that wire cables may encounter. Through a series of processes, these rods are transformed into wire cables capable of efficiently transmitting signals while maintaining their mechanical integrity.

- Q: What are the different heat treatment processes applied to steel wire rod?

- There are several heat treatment processes applied to steel wire rod, including annealing, quenching, tempering, and normalizing. Annealing involves heating the wire rod to a specific temperature and then slowly cooling it, which helps to reduce internal stress and improve its ductility. Quenching involves rapidly cooling the wire rod after heating it to a high temperature, which results in increased hardness and strength. Tempering is a process that follows quenching, in which the wire rod is reheated to a lower temperature to reduce brittleness and enhance toughness. Normalizing is a heat treatment process similar to annealing, but the cooling is done in still air, which helps to refine the grain structure and improve the mechanical properties of the wire rod.

- Q: What are the different annealing processes used for steel wire rod?

- The different annealing processes used for steel wire rod include full annealing, spheroidization annealing, and process annealing. Full annealing involves heating the wire rod to a temperature above its critical temperature and then slowly cooling it to room temperature to soften it and improve its ductility. Spheroidization annealing is a type of full annealing that is specifically used for high carbon steel wire rod to transform its brittle cementite structure into spherical carbides, enhancing its machinability and reducing the risk of breakage. Process annealing, on the other hand, is a partial annealing process that is performed on cold-worked wire rod to relieve internal stresses and restore some of its ductility without affecting its mechanical properties.

- Q: What are the different types of steel wire rod finishes for improved adhesion in rubber products?

- There are several types of steel wire rod finishes that can enhance adhesion in rubber products. Some common finishes include copper, zinc, phosphate, and brass coatings. These finishes help to create a stronger bond between the steel wire rod and the rubber, improving adhesion and overall product performance.

- Q: How is steel wire rod used in the manufacturing of wire forms for security fencing?

- Steel wire rod is an essential component in the manufacturing of wire forms for security fencing. It serves as the main raw material for creating durable and strong wire fences. Firstly, steel wire rod is processed through a series of mechanical and chemical treatments to enhance its properties, such as strength, flexibility, and corrosion resistance. This ensures that the wire forms produced from it can withstand harsh weather conditions, physical impact, and attempts of breaching. Once the steel wire rod is prepared, it is then formed into various shapes and sizes to fit the specific requirements of security fencing. This can include straight wires, coils, or even intricate designs like barbed wire or razor wire, depending on the level of security desired. The wire forms are then assembled and connected to create the desired security fence structure. This can involve weaving, welding, or fastening the wire forms together using specialized tools and techniques. The strength and durability of the steel wire rod ensures that the fence will maintain its structural integrity and resist any attempts to cut, break, or tamper with it. Moreover, steel wire rod can also be galvanized or coated with protective layers to enhance its resistance to corrosion, rust, and other environmental factors. This further increases the lifespan of the security fence and reduces the need for frequent maintenance or replacement. In summary, steel wire rod plays a crucial role in the manufacturing of wire forms for security fencing. Its strength, durability, and resistance to corrosion make it an ideal material for creating robust and long-lasting fences that provide effective security measures.

Send your message to us

Hot sale types of steel wire rope 1*7 1*19 7*19

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords