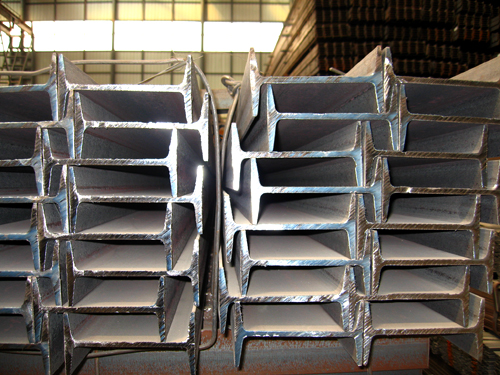

Hot Rolled Steel I-Beam with good quality from china

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

OKorder is offering Hot Rolled Steel I-Beam with good quality from china at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled Steel I-Beam with good quality from china applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel I-Beams are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

Chinese Standard (H*W*T) | Weight (Kg/m) | 6m (pcs/ton) | Light I (H*W*T) | Weight (Kg/m) | 6m (pcs/ton) | Light II (H*W*T) | Weight (Kg/m) | 6M |

100*68*4.5 | 11.261 | 14.8 | 100*66*4.3 | 10.13 | 16.4 | 100*64*4 | 8.45 | 19.7 |

120*74*5.0 | 13.987 | 11.9 | 120*72*4.8 | 12.59 | 13.2 | 120*70*4.5 | 10.49 | 15.8 |

140*80*5.5 | 16.89 | 9.8 | 140*78*5.3 | 15.2 | 10.9 | 140*76*5 | 12.67 | 13.1 |

160*88*6 | 20.513 | 8.1 | 160*86*5.8 | 18.46 | 9 | 160*84*5.5 | 15.38 | 10.8 |

180*94*6.5 | 24.143 | 6.9 | 180*92*6.3 | 21.73 | 7.6 | 180*90*6 | 18.11 | 9.2 |

200*100*7 | 27.929 | 5.9 | 200*98*6.8 | 25.14 | 6.6 | 200*96*6.5 | 20.95 | 7.9 |

220*110*7.5 | 33.07 | 5 | 220*108*7.3 | 29.76 | 5.6 | 220*106*7 | 24.8 | 6.7 |

250*116*8 | 38.105 | 4.3 | 250*114*7.8 | 34.29 | 4.8 | 250*112*7.5 | 28.58 | 5.8 |

280*122*8.5 | 43.492 | 3.8 | 280*120*8.2 | 39.14 | 4.2 | 280*120*8 | 36.97 | 4.5 |

300*126*9 | 48.084 | 3.4 | 300*124*9.2 | 43.28 | 3.8 | 300*124*8.5 | 40.87 | 4 |

320*130*9.5 | 52.717 | 3.1 | 320*127*9.2 | 48.5 | 3.4 | |||

360*136*10 | 60.037 | 2.7 | 360*132*9.5 | 55.23 | 3 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Images:

- Q: What are the different finishes available for steel H-beams?

- There are several different finishes available for steel H-beams, including hot-dip galvanizing, primed, painted, and bare steel.

- Q: Can steel H-beams be used for long-span structures?

- Yes, steel H-beams can be used for long-span structures. Steel H-beams are commonly used in construction due to their high strength-to-weight ratio and versatility. They are capable of spanning long distances without the need for additional support columns or beams. The H-shape provides structural stability and distributes the load evenly, making it suitable for long-span structures such as bridges, high-rise buildings, and industrial facilities. Additionally, steel H-beams can be easily fabricated and connected, allowing for efficient construction and customization to meet specific design requirements. Overall, steel H-beams are a popular choice for long-span structures due to their strength, durability, and cost-effectiveness.

- Q: Are steel H-beams suitable for structures with high ceilings?

- Steel H-beams are indeed a suitable choice for structures that have high ceilings. Construction projects often rely on H-beams because of their impressive strength and ability to bear heavy loads. These beams are specifically designed to provide stability to the structure and support substantial weights. The unique H-shape of the beams enables them to efficiently distribute the weight, which makes them especially well-suited for structures with high ceilings that may experience heightened vertical loads. Moreover, steel H-beams possess durability and resistance against environmental factors like fire, moisture, and pests. Consequently, they are a dependable option for ensuring long-term structural integrity.

- Q: How do steel H-beams compare to timber or concrete beams?

- Steel H-beams have several advantages over timber or concrete beams. Firstly, steel H-beams are much stronger and more durable than timber or concrete beams. Steel has a higher strength-to-weight ratio, meaning that it can support heavier loads while being lighter in weight. This allows for longer spans and larger open spaces in construction. In contrast, timber beams are prone to warping, rotting, or insect damage, while concrete beams may crack or deteriorate over time. Secondly, steel H-beams are more resistant to fire and other extreme conditions. Steel has a high melting point and does not burn, making it a safer choice in case of fire accidents. Timber beams, on the other hand, are highly flammable and can contribute to the rapid spread of fire. Concrete beams may also crack and fail under extreme heat or cold conditions. Furthermore, steel H-beams offer better flexibility and versatility in design. They can be easily fabricated into various shapes, sizes, and lengths to meet specific project requirements. Steel beams also have consistent dimensions, allowing for easier and faster installation. In contrast, timber beams are limited in terms of available sizes and may require additional processing. Concrete beams are typically cast on-site, which can be time-consuming and labor-intensive. Lastly, steel H-beams have a longer lifespan and require less maintenance compared to timber or concrete beams. Steel is resistant to corrosion, rot, and decay, making it a more durable and cost-effective choice in the long run. Timber beams need regular inspections, treatments, and replacements to maintain their structural integrity. Concrete beams may develop cracks or require repairs over time. In summary, steel H-beams offer superior strength, durability, fire resistance, design versatility, and low maintenance compared to timber or concrete beams. These advantages make steel H-beams a preferred choice in many construction projects, especially those with higher load-bearing requirements or in locations prone to extreme conditions.

- Q: Can steel H-beams be used for supporting roller coasters or amusement park rides?

- Steel H-beams have the capacity to support roller coasters and amusement park rides. They are frequently employed in construction and engineering sectors owing to their exceptional strength-to-weight ratio, rendering them suitable for bearing heavy loads. Given that roller coasters and amusement park rides often entail substantial weight and dynamic forces, the utilization of steel H-beams as support structures guarantees stability and safety. Moreover, steel H-beams possess durability and corrosion resistance, which proves advantageous in outdoor amusement park settings exposed to diverse weather conditions. In conclusion, steel H-beams constitute a dependable and widely utilized option for supporting roller coasters and amusement park rides.

- Q: Can steel H-beams be used for both indoor and outdoor applications?

- Steel H-beams are applicable for both indoor and outdoor purposes. They possess versatility and are extensively utilized in diverse construction projects owing to their strength, durability, and load-bearing capacity. Whether it is for indoor structures like buildings, warehouses, or bridges, or outdoor applications including canopies, pavilions, or outdoor walkways, steel H-beams are suitable for both settings. They exhibit resistance towards environmental elements such as moisture, heat, and corrosion, thereby making them ideal for outdoor usage. Moreover, steel H-beams can be coated or painted to enhance their resistance against weather conditions and prolong their lifespan, thereby ensuring their suitability for outdoor applications.

- Q: Do steel H-beams require additional bracing?

- Yes, steel H-beams typically require additional bracing to provide stability and prevent buckling or lateral movement under load.

- Q: Can steel H-beams be used for gymnasiums?

- Gymnasiums can indeed utilize steel H-beams. Due to their robustness and structural soundness, steel H-beams are widely employed in construction. They provide exceptional support for substantial spans and heavy loads, making them ideal for gymnasiums, which often necessitate expansive areas and lofty ceilings. Moreover, steel H-beams can be effortlessly tailored and manufactured to meet specific design prerequisites, granting flexibility in gymnasium design. Their resilience and ability to withstand fire, pests, and structural deterioration also establish them as a dependable choice for gymnasium construction. All in all, steel H-beams represent a favored and efficient alternative for constructing gymnasiums.

- Q: Are there any regulations or standards for using steel H-beams in construction?

- Steel H-beams in construction are subject to regulations and standards, which differ depending on the country and region. These regulations ensure the safe and effective use of H-beams in building structures. In the United States, the American Institute of Steel Construction (AISC) is responsible for providing standards for steel construction, including H-beams. The AISC's Manual of Steel Construction outlines the criteria for design, fabrication, and safety considerations when using H-beams in construction. These standards cover topics such as material specifications, design principles, welding procedures, and quality control measures. Similarly, in Europe, the European Committee for Standardization (CEN) has developed the Eurocodes, which are a set of harmonized technical rules for the design of structures, including steel H-beams. The Eurocodes cover various aspects of construction, including structural design, material properties, and construction execution. The Eurocodes ensure that H-beams used in construction projects meet the necessary safety, performance, and durability standards. Different regulations and standards exist in other countries and regions for the use of steel H-beams in construction. These standards typically address issues such as material properties, structural design criteria, fabrication and construction practices, and quality control measures. Compliance with these regulations is crucial for contractors, engineers, and designers to ensure the structural integrity and safety of buildings that use steel H-beams. To ensure compliance with all applicable regulations and standards, it is important to consult the relevant local building codes and standards. Additionally, engaging the services of qualified professionals, such as structural engineers, during the design and construction stages is highly recommended.

- Q: What are the maximum spans for steel H-beams?

- The maximum spans for steel H-beams vary depending on various factors such as the size and type of the H-beam, the load it needs to support, and the design considerations. It is recommended to consult structural engineers or reference structural design codes and standards for specific information on maximum spans for steel H-beams in different applications.

Send your message to us

Hot Rolled Steel I-Beam with good quality from china

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords