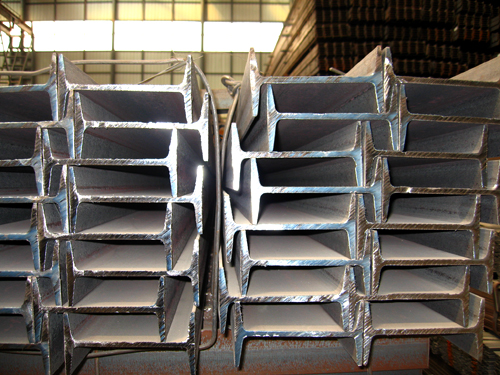

Hot Rolled Steel I-Beam with good quality for steel support

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

OKorder is offering Hot Rolled Steel I-Beam with good quality for steel support at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled Steel I-Beam with good quality for steel support applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel I-Beams are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS,

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

Chinese Standard (H*W*T) | Weight (Kg/m) | 6m (pcs/ton) | Light I (H*W*T) | Weight (Kg/m) | 6m (pcs/ton) | Light II (H*W*T) | Weight (Kg/m) | 6M |

100*68*4.5 | 11.261 | 14.8 | 100*66*4.3 | 10.13 | 16.4 | 100*64*4 | 8.45 | 19.7 |

120*74*5.0 | 13.987 | 11.9 | 120*72*4.8 | 12.59 | 13.2 | 120*70*4.5 | 10.49 | 15.8 |

140*80*5.5 | 16.89 | 9.8 | 140*78*5.3 | 15.2 | 10.9 | 140*76*5 | 12.67 | 13.1 |

160*88*6 | 20.513 | 8.1 | 160*86*5.8 | 18.46 | 9 | 160*84*5.5 | 15.38 | 10.8 |

180*94*6.5 | 24.143 | 6.9 | 180*92*6.3 | 21.73 | 7.6 | 180*90*6 | 18.11 | 9.2 |

200*100*7 | 27.929 | 5.9 | 200*98*6.8 | 25.14 | 6.6 | 200*96*6.5 | 20.95 | 7.9 |

220*110*7.5 | 33.07 | 5 | 220*108*7.3 | 29.76 | 5.6 | 220*106*7 | 24.8 | 6.7 |

250*116*8 | 38.105 | 4.3 | 250*114*7.8 | 34.29 | 4.8 | 250*112*7.5 | 28.58 | 5.8 |

280*122*8.5 | 43.492 | 3.8 | 280*120*8.2 | 39.14 | 4.2 | 280*120*8 | 36.97 | 4.5 |

300*126*9 | 48.084 | 3.4 | 300*124*9.2 | 43.28 | 3.8 | 300*124*8.5 | 40.87 | 4 |

320*130*9.5 | 52.717 | 3.1 | 320*127*9.2 | 48.5 | 3.4 | |||

360*136*10 | 60.037 | 2.7 | 360*132*9.5 | 55.23 | 3 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Images:

- Q: Can steel H-beams be used in mezzanine or elevated flooring systems?

- Yes, steel H-beams can be used in mezzanine or elevated flooring systems. Steel H-beams are often used in construction due to their high strength and load-bearing capacity. They provide structural support and stability, making them suitable for creating elevated flooring systems such as mezzanines. The H shape of the beam helps distribute the weight evenly, allowing for larger spans and increased floor space. Additionally, steel H-beams can be easily connected and integrated into the overall structure, making them a popular choice for mezzanine and elevated flooring systems.

- Q: Can steel H-beams be used for cantilever structures?

- Certainly! Cantilever structures can indeed make use of steel H-beams. These structures are specifically designed to incorporate a projecting beam or member that is supported on just one end, while the other end remains free or unsupported. Steel H-beams are widely employed in the realm of construction due to their remarkable strength and ability to bear substantial loads. They are particularly well-suited for cantilever designs as they offer exceptional structural support, effectively minimizing deflection and ensuring overall stability. Nonetheless, it is imperative to take into account the specific requirements of the cantilever structure. In order to determine the appropriate size and strength of the H-beam necessary to support the desired load and span, it is highly recommended to seek guidance from a structural engineer.

- Q: How can steel H-beams be protected from corrosion?

- Steel H-beams can be protected from corrosion through various methods such as applying a protective coating, galvanizing the beams, or using corrosion inhibitors. These techniques create a barrier between the steel and the corrosive elements, preventing rust formation and extending the lifespan of the H-beams.

- Q: Do you have H steel 550x300x11x18?

- It can be made of welded H section steel. Five thousand and two hundred outbound.

- Q: What are the potential drawbacks or limitations of using steel H-beams?

- There are several potential drawbacks or limitations associated with using steel H-beams in construction projects. Firstly, steel H-beams can be quite heavy and bulky, making them difficult to handle and transport. This can increase the overall cost and time required for construction projects, as specialized equipment and labor may be needed to move and position these beams. Secondly, steel H-beams are susceptible to corrosion, particularly in environments with high levels of moisture or chemicals. Without proper maintenance and protective coatings, the beams can deteriorate over time, compromising their structural integrity and durability. This can lead to safety concerns and the need for frequent inspections and repairs. Another limitation of steel H-beams is their susceptibility to fire. Steel has a relatively high melting point, but when exposed to high temperatures, it can lose its strength and structural integrity. This can result in the collapse of the building or structure, posing significant risks to occupants and neighboring properties. Additionally, steel H-beams have limited flexibility compared to other construction materials, such as wood or concrete. This can restrict the design possibilities and architectural creativity of a project, as steel beams often require specific engineering calculations and constraints. Lastly, the cost of steel H-beams can be a limiting factor for some construction projects. Steel is generally more expensive than alternative materials, and the price can fluctuate depending on market conditions and availability. This can impact the overall budget and feasibility of a project, especially for smaller-scale or budget-conscious developments. In summary, while steel H-beams offer various advantages in terms of strength and load-bearing capacity, they also come with drawbacks and limitations related to their weight, susceptibility to corrosion and fire, lack of flexibility, and higher cost. It is important for architects, engineers, and project managers to carefully consider these factors when deciding on the appropriate construction materials for their specific projects.

- Q: Can steel H-beams be used in wastewater treatment plants?

- Yes, steel H-beams can be used in wastewater treatment plants. Steel H-beams offer excellent strength and durability, making them suitable for various structural applications in wastewater treatment plants. They can be used for supporting heavy equipment and machinery, constructing platforms and walkways, and providing structural support for various treatment processes. Additionally, steel H-beams are resistant to corrosion, which is essential in an environment with high levels of moisture and chemicals. With proper coatings and maintenance, steel H-beams can provide long-lasting and reliable support in wastewater treatment plants.

- Q: How do Steel H-Beams contribute to the overall life cycle assessment of a structure?

- There are several ways in which steel H-beams contribute to the overall life cycle assessment of a structure. Firstly, these beams are widely used in buildings, bridges, and other infrastructure projects because they are strong and durable. The use of steel H-beams in construction ensures the structure's longevity and stability, which is essential for its life cycle assessment. Moreover, steel H-beams have a high rate of recyclability, meaning they can be easily recovered and reused at the end of their life cycle. This promotes sustainability and reduces the environmental impact of the structure. Steel is one of the most recycled materials globally, and the use of H-beams supports the circular economy by minimizing waste and conserving natural resources. Additionally, the manufacturing process of steel H-beams has become more energy-efficient and environmentally friendly over time. Advanced technologies like electric arc furnaces and energy recovery systems are used to decrease energy consumption and greenhouse gas emissions during production. This improvement positively affects the life cycle assessment by reducing the embodied energy and carbon footprint of the structure. Furthermore, steel H-beams are known for their design flexibility and adaptability. They can be easily modified or replaced, allowing for future structural modifications or repurposing of the building. This adaptability extends the structure's life cycle and reduces the need for complete demolition and reconstruction, which would have a significant environmental impact. To summarize, steel H-beams contribute to the overall life cycle assessment of a structure by providing strength, durability, and stability. Their high recyclability, energy-efficient manufacturing, and design flexibility promote sustainability and minimize environmental impacts. By considering the use of steel H-beams in construction projects, we can enhance the overall performance and longevity of structures while reducing their ecological footprint.

- Q: What are the different design codes and standards for steel H-beams?

- Some of the different design codes and standards for steel H-beams include the American Institute of Steel Construction (AISC) 360, Eurocode 3, British Standards (BS) 5950, and the Canadian Standards Association (CSA) S16. These codes and standards provide guidelines and specifications for the design, fabrication, and construction of steel H-beams, ensuring structural integrity and safety.

- Q: Can steel H-beams be used in shopping malls and commercial complexes?

- Certainly, shopping malls and commercial complexes can utilize steel H-beams. These beams are extensively employed in the construction sector owing to their exceptional structural stability and strength. Their ability to bear substantial loads makes them perfectly suited for accommodating heavy burdens within expansive commercial areas. Furthermore, steel H-beams offer design flexibility and can be seamlessly incorporated with various other construction materials. Their longevity and resilience against fire and corrosion render them a dependable option for prolonged usage in shopping malls and commercial complexes.

- Q: What are the durability considerations for steel H-beams?

- When considering the durability of steel H-beams, there are several factors that need to be taken into account. Firstly, the durability of these beams is determined significantly by the quality and grade of the steel used in their construction. Steels with higher grades, which possess increased tensile strength and corrosion resistance, tend to have better longevity. Another important consideration is the application of protective coatings to the H-beams. Coatings like galvanization or epoxy can enhance the durability of the steel by creating a barrier against corrosion and other environmental factors. It is necessary to regularly maintain and inspect these coatings to ensure their long-term effectiveness. Additionally, the load-bearing capacity of the steel H-beams must be evaluated to determine their durability. Adequate design and engineering must be employed to ensure that the beams can endure the expected loads and stresses without deforming or failing. The durability of steel H-beams can also be impacted by environmental conditions, such as exposure to moisture, extreme temperatures, or chemicals. Proper precautions, including the use of suitable coatings, ventilation, and drainage systems, should be implemented to minimize the potential negative effects of these conditions. Lastly, the installation and connection methods used for steel H-beams can affect their durability. It is crucial to utilize proper welding, bolted connections, or other joining techniques to securely fasten the beams together and enable them to withstand the anticipated forces and movements without compromising their structural integrity. In conclusion, the durability of steel H-beams depends on various factors, including the quality of the steel, protective coatings, load-bearing capacity, environmental conditions, and proper installation and connections. By considering these aspects and implementing necessary measures, the long-term durability of steel H-beams can be ensured in different applications.

Send your message to us

Hot Rolled Steel I-Beam with good quality for steel support

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords