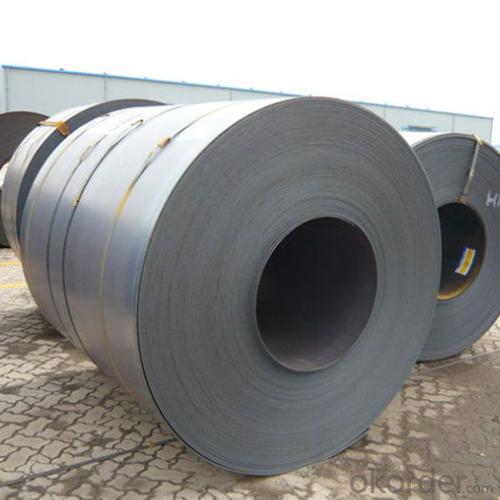

Hot Rolled Steel Coils,Hot Rolled Steel Plates Thickness 5.0

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 200000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

DESCRIPTION FOR SS400 CARBON STEEL SHEET

1.Thickness: 1-200mm

2.Width: 100-3000mm

3.Length: 1000-12000mm

4. Applications :mining machinery, environmental protection, engineering

5. Grade:SS400 A 36 Q195.Q235.Q345.SPCC.SPCH

6.Surface : Hot Rolled Cold Rolled Galvanized Steel

DESCRIPTION FOR CARBON STEEL PLATE

Product | carbon steel plate price per ton |

Place of origin | Tianjin,China mainland |

MOQ | 25 tons |

Thickness | 1mm-200mm |

Width | 1000mm-3000mm |

Length | 1000mm-2000mm |

Application | widely |

Standard | AISI,ASTM,BS,DIN,JIS,GB,etc |

Grade | A572,A573,A633,A678,A709,A710,G3101,G3136,etc |

Tpye | Steel plate |

Surfacing | Coated |

Productive Technology | Hot Rolled & Cold Rolled |

Price | FOB USD 500-900 per ton |

Port | TIANJIN,SHANGHAI |

Payment Terms | L/C,T/T,Western Union,MoneyGram |

Product Ability | 1000 tons per month |

Delivery | 10 days after deposit or according to customers' quantity |

Packing | standard seaworthy export packing or as the request of customers |

FEATURES OF STEEL COILS

(1)Good ductility

(2)Good corrosion resistance

(3)Excellent abrasion resistance and fatigue strength

(4)Good weldability

(5)Oxidation resistant performance

(6)Excellent in high temperature

PACKING:

1.Big thickness:by bulk vessel

2.Small thickness:packed by steel strips and shipped by container

3.According to the requirements of customers'

TRADE TERMS :FOB, CFR, CIF

DETAILED PICTURES FOR STEEL COILS

FAQ:

Q:You are Factory or Trading Company?

A:We are factory,our main products include Steel plate,Steel Bar,Steel coils.

Q:What’s the MOQ?

A:Generally,the trail order will be accepted.The MOQ can be confirmed according to the different products.For example,the MOQ of rebar will be 25-50MT,the galvanized steel pipe will be 10MT,the stainless steel pipe will 1-5MT.

- Q: What's the difference between the 304 stainless steel plate and the 310S stainless steel plate?

- 304 stainless steel is a common stainless steel material, the density of 7.93 g/cm3, the industry is also called 18/8 stainless steel. High temperature resistance of 800 degrees, with good processability, high toughness characteristics, widely used in industry and furniture decoration industry and food and medical industry.

- Q: Can stainless steel sheets be used for elevator mirrors?

- Yes, stainless steel sheets can be used for elevator mirrors. Stainless steel is a durable and corrosion-resistant material that can provide a sleek and modern aesthetic for elevator mirrors.

- Q: What are the benefits of using brushed stainless steel sheets?

- There are several benefits of using brushed stainless steel sheets. Firstly, brushed stainless steel has an attractive and sleek appearance, making it a popular choice for various applications such as appliances, countertops, and backsplashes. The brushed finish gives the metal a unique texture and a matte appearance, which adds a touch of sophistication to any space. Secondly, brushed stainless steel sheets are highly durable and resistant to corrosion, making them suitable for both indoor and outdoor use. This material is known for its strength and ability to withstand harsh conditions, such as chemicals, moisture, and extreme temperatures. It is also easy to clean and maintain, as the brushed finish helps to hide fingerprints, smudges, and scratches. Additionally, brushed stainless steel sheets are hygienic and resistant to bacteria growth, making them ideal for applications in the food and medical industries. The smooth surface of the metal makes it easy to clean and disinfect, ensuring a safe and sanitary environment. Furthermore, brushed stainless steel sheets offer excellent longevity and longevity, making them a cost-effective investment. This material is known for its resistance to wear and tear, meaning it can withstand heavy use and maintain its appearance for many years without needing to be replaced. Lastly, brushed stainless steel sheets are versatile and can be easily customized to fit different design preferences. They can be cut, shaped, and formed into various sizes and shapes, allowing for endless design possibilities. Whether you prefer a modern, industrial look or a more traditional and elegant style, brushed stainless steel sheets can be tailored to suit your specific needs. In conclusion, the benefits of using brushed stainless steel sheets include their attractive appearance, durability, corrosion resistance, hygienic properties, longevity, and versatility. Whether for residential, commercial, or industrial use, brushed stainless steel sheets offer a wide range of advantages that make them a popular choice for many applications.

- Q: Can stainless steel sheets be used for heat recovery systems?

- Yes, stainless steel sheets can be used for heat recovery systems. Stainless steel is widely recognized for its high thermal conductivity and corrosion resistance, making it an ideal material for heat transfer applications. In heat recovery systems, stainless steel sheets are often used as heat exchanger plates or tubes due to their ability to efficiently transfer heat from one fluid to another. The corrosion resistance of stainless steel ensures the longevity and reliability of the heat recovery system, even when exposed to high temperatures and aggressive environments. Additionally, stainless steel sheets can withstand thermal expansion and contraction, making them suitable for various heat recovery system designs. Overall, stainless steel sheets are a popular choice in heat recovery systems due to their excellent heat transfer properties, durability, and resistance to corrosion.

- Q: Can stainless steel sheets be cut to size?

- Yes, stainless steel sheets can be cut to size using various cutting methods such as shearing, laser cutting, or waterjet cutting.

- Q: Are stainless steel sheets good for pressure vessels?

- Stainless steel sheets have gained popularity as a preferred choice for pressure vessels due to their durability, reliability, and ability to meet the demanding requirements of such applications. Commonly employed, they are considered to be an excellent option. Stainless steel possesses exceptional resistance to corrosion, high strength, and commendable mechanical properties, rendering it suitable for applications that necessitate withstanding high pressures. Moreover, stainless steel exhibits remarkable heat resistance, a pivotal trait in pressure vessels where exposure to elevated temperatures is likely. It is also important to highlight that stainless steel lends itself to easy formation and welding, facilitating the fabrication of intricate shapes and designs required for pressure vessel construction. All in all, stainless steel sheets are a favored material for pressure vessels due to their ability to endure, their dependability, and their capacity to fulfill the demanding prerequisites of such applications.

- Q: Can stainless steel sheets be formed into different shapes?

- Stainless steel sheets possess the capability to assume diverse shapes. Such sheets are composed of a flexible material, which can be effortlessly altered using multiple techniques like bending, rolling, and stretching. Consequently, stainless steel sheets can be transformed into a wide array of configurations, encompassing curves, angles, cylinders, and intricate geometries. The pliability and ductility of these sheets render them exceptionally suitable for applications necessitating personalized shapes and designs. Moreover, owing to its resistance against corrosion and high temperatures, stainless steel is extensively utilized in shaping various forms within industries such as architecture, construction, automotive, and manufacturing.

- Q: What is the modulus of elasticity of stainless steel sheets?

- The stiffness or rigidity of a material can be determined by its modulus of elasticity, which is commonly referred to as Young's modulus. In the case of stainless steel sheets, the modulus of elasticity usually falls within the range of 190 to 200 gigapascals (GPa). Nevertheless, it is crucial to acknowledge that the modulus of elasticity is subject to variation based on factors like the precise type and grade of stainless steel, as well as temperature and strain rate.

- Q: Can stainless steel sheets be used for pharmaceutical storage cabinets?

- Yes, stainless steel sheets can be used for pharmaceutical storage cabinets. Stainless steel is a preferred material in the pharmaceutical industry due to its hygiene, durability, and resistance to corrosion, making it suitable for storing pharmaceutical products safely and maintaining their quality.

- Q: How do you prevent chloride-induced corrosion in stainless steel sheets?

- One effective way to prevent chloride-induced corrosion in stainless steel sheets is by ensuring proper maintenance and cleaning. Regularly removing any accumulated chlorides and contaminants from the surface of the stainless steel sheets through thorough cleaning with mild detergents or specialized cleaning solutions can help minimize the risk of corrosion. Additionally, applying protective coatings or passivation treatments to the stainless steel sheets can create a barrier between the metal and chloride ions, further reducing the potential for corrosion.

Send your message to us

Hot Rolled Steel Coils,Hot Rolled Steel Plates Thickness 5.0

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 200000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords