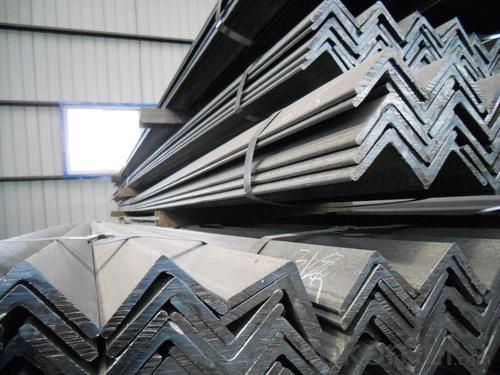

Hot Rolled Equal Angle Steel with High Quality Hot Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Hot Rolled Carbon Steel Equal Angle at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc.

Product Advantages:

OKorder's Equal Angle are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

1. Invoicing on theoretical weight or actual weight as customer request

2. Length: 6m, 9m, 12m as following table

3. Sizes

Sizes: 25mm-250mm | ||

a*t | ||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 |

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 |

36*3.0-5.0 | 80*5.0-10 | 150*10-20 |

38*2.3-6.0 | 90*7.0-10 | 160*10-16 |

40*3.0-5.0 | 100*6.0-12 | 175*12-15 |

45*4.0-6.0 | 110*8.0-10 | 180*12-18 |

50*4.0-6.0 | 120*6.0-15 | 200*14-25 |

60*4.0-8.0 | 125*8.0-14 | 250*25 |

4.Material details:

Alloy No | Grade | Element (%) | |||||

C | Mn | S | P | Si | |||

Q235 | B | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 | |

Alloy No | Grade | Yielding strength point( Mpa) | |||||

Thickness (mm) | |||||||

≤16 | >16--40 | >40--60 | >60--100 | ||||

≥ | |||||||

Q235 | B | 235 | 225 | 215 | 205 | ||

Alloy No | Grade | Tensile strength (Mpa) | Elongation after fracture (%) | ||||

Thickness (mm) | |||||||

≤16 | >16--40 | >40--60 | >60--100 | ||||

≥ | |||||||

Q235 | B | 375--500 | 26 | 25 | 24 | 23 | |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: What makes stainless steel stainless?

A3: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

- Q: Can steel angles be used for reinforcing steel structures?

- Steel angles are capable of reinforcing steel structures. Their versatility and widespread use in construction projects stem from their strength and durability. Steel angles serve as reinforcements to fortify and provide additional support to steel structures including beams, columns, and trusses. To enhance the overall structural integrity of steel structures, steel angles are often used in conjunction with other reinforcing materials such as steel bars or mesh. The angle shape of steel angles facilitates easy welding or bolting, making them a popular choice for reinforcing steel structures. Moreover, steel angles are available in various sizes and thicknesses, offering flexibility in design and application. All in all, steel angles prove to be an effective and commonly employed option for reinforcing steel structures.

- Q: Can steel angles be used in transportation or infrastructure projects?

- Yes, steel angles can be used in transportation or infrastructure projects. Steel angles are commonly used in construction due to their strength and durability. They are often used to provide structural support and stability in various applications such as bridges, buildings, highways, and railways. In transportation projects, steel angles can be used for constructing vehicle ramps, guardrails, and support structures for overhead signs. In infrastructure projects, they can be used for constructing retaining walls, foundations, and supporting structures for utility installations. The versatility and reliability of steel angles make them a popular choice in these types of projects.

- Q: Can steel angles be used in earthquake-prone areas?

- Yes, steel angles can be used in earthquake-prone areas. Steel is a highly durable and strong material that can withstand seismic forces better than other construction materials like wood or concrete. Steel angles, in particular, are commonly used in seismic-resistant designs, as they provide structural support and help distribute the seismic forces throughout the building. Steel angles are designed to resist bending and twisting, making them ideal for earthquake-resistant construction. They are often used in the construction of steel moment frames, which are known for their ability to absorb and dissipate seismic energy. These frames provide a rigid structural system that helps to prevent the collapse of buildings during earthquakes. Furthermore, steel angles can be easily bolted or welded together, allowing for quick and efficient construction. This flexibility in design and construction makes steel angles a popular choice for earthquake-prone areas, where buildings need to be able to withstand high-intensity seismic events. However, it is important to note that the effectiveness of steel angles in earthquake-prone areas also depends on various factors, such as the specific building design, the quality of materials used, and adherence to building codes and regulations. Proper engineering and design considerations should always be followed to ensure the safe and reliable use of steel angles in such areas.

- Q: Do steel angles have a smooth or textured surface?

- Steel angles generally possess a textured exterior, which is formed when the steel is either hot-rolled or cold-formed into the angled shape during the manufacturing process. As a consequence, the steel angles acquire a slightly uneven or knobby surface, enhancing their ability to offer improved grip and stability in diverse applications. Furthermore, this texture serves to deter objects from slipping or sliding when they come into contact with the steel angles. Nevertheless, it should be noted that the degree of texture can differ based on the particular manufacturing technique employed and the intended purpose of the steel angles.

- Q: Are steel angles suitable for manufacturing structural beams?

- Yes, steel angles are suitable for manufacturing structural beams. Steel angles, also known as L-shaped structural steel, are commonly used in the construction industry to create structural beams due to their strength and versatility. Steel angles offer excellent load-bearing capabilities and are able to withstand heavy loads and forces, making them ideal for constructing beams that can support the weight of buildings, bridges, and other structures. Additionally, steel angles can be easily welded, bolted, or otherwise connected to form larger structural components, providing flexibility in design and construction. Overall, steel angles are a reliable and efficient choice for manufacturing structural beams.

- Q: Can steel angles be used for roof trusses?

- Yes, steel angles can be used for roof trusses. Steel angles are commonly used in construction for their strength and durability. They can be easily fabricated and installed to create the framework for roof trusses. Steel angles provide excellent support and stability, making them suitable for use in various roofing applications. Additionally, steel angles can withstand heavy loads and adverse weather conditions, making them a reliable choice for roof trusses.

- Q: What are the maximum allowable lengths for steel angles?

- The maximum allowable lengths for steel angles can vary depending on the specific application and the regulations and guidelines set forth by the relevant industry standards. Generally, the maximum allowable lengths for steel angles are determined by factors such as the material's strength, the load it is intended to bear, and the structural design considerations. In construction and engineering industries, steel angles are commonly used for various structural applications such as framing, bracing, and support. The maximum allowable lengths for steel angles are often specified by building codes, engineering standards, or project-specific design criteria. These regulations ensure that the angles can withstand the expected loads and provide adequate structural stability. It is important to consult the appropriate industry standards and regulations, as well as consult with a qualified structural engineer or designer, to determine the maximum allowable lengths for steel angles in a specific application. These professionals take into account factors such as the angle's dimensions, thickness, material properties, and the specific load requirements to determine the appropriate length that can safely and effectively meet the project requirements.

- Q: What is the maximum deflection allowed for steel angles?

- The maximum deflection allowed for steel angles depends on several factors, including the specific grade of steel, the length of the angle, and the applied load. Generally, in structural engineering, deflection limits are set to ensure the safety and performance of the structure. The deflection limit for steel angles is typically defined as a fraction of the span length, such as L/240 or L/360, where L represents the unsupported length of the angle. For example, if the unsupported length of a steel angle is 240 inches, the maximum deflection allowed would be 1 inch (240/240) or 0.67 inches (240/360). However, it is important to note that these deflection limits may vary depending on the specific design codes and standards being used for the project. Consulting the relevant code or seeking guidance from a structural engineer would provide more accurate and specific information regarding the maximum deflection allowed for steel angles in a particular application.

- Q: What is the typical length of a steel angle?

- The typical length of a steel angle can vary depending on the specific application or project requirements. However, standard lengths for steel angles often range from 10 to 20 feet.

- Q: Can steel angles be bolted or fastened together?

- Yes, steel angles can be bolted or fastened together.

Send your message to us

Hot Rolled Equal Angle Steel with High Quality Hot Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords