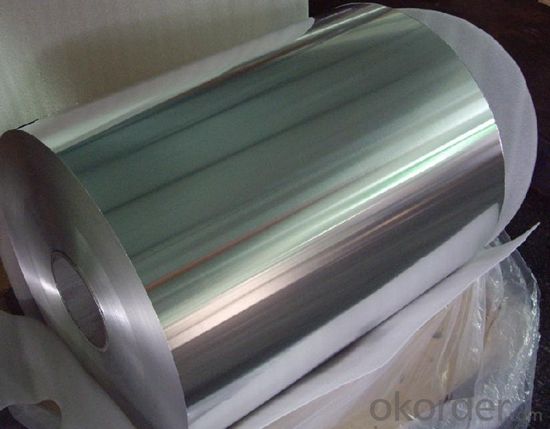

Aluminum Hot Rolled Coils for Tanker and Trailer Manufacturing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

Alloy: 5052(AlMg2.5)

Temper: O,H12,H22,H32,H14,H24,H34,H16,H26,H36,H18,H38,F

CHEMICAL COMPOSITION LIMITS (%)

Silicon | Iron | Copper | Manganese | Magnesium | Chromium | Nickel | Zinc | Titanium | Others | Total | Aluminum |

0.25 | 0.4 | 0.10 | 0.10 | 2.2-2.8 | 0.15-0.35 | 0.10 | 0.05 | 0.15 |

Remainder |

Main application: Magnesium gives this alloy its enhanced corrosion resistance, workability, strength and weldability. Typical uses include aircraft fuel tanks, container body, truck/trailer body, electronic mounting plates and panels, fan blades, refrigeration liners, storm shutters and utensils.

Mechanical Property Limits

Alloy | Temper | Thickness(mm) | Tensile Strength(MPa) | Elg%(50mm) |

5052 | O | >0.5-0.8 >0.8-1.3 >1.3-6.5 >6.5-10.0 | 170-215

| ≥15 ≥17 ≥19 ≥18 |

H12/H22/H32 | >0.5-1.3 >1.3-4.5 | 215-265 | ≥5 ≥7 | |

H14/H24/H34 | >0.5-0.8 >0.8-1.3 >1.3-4.5 | 235-285 | ≥3 ≥4 ≥6 | |

H16/H26/H36 | >0.5-0.8 >0.8-4.5 | 255-305 | ≥3 ≥4 | |

H18/H38 | >0.5-0.8 >0.8-4.5 | ≥270 | ≥3 ≥4 | |

H112 | >4.5-6.5 | ≥195 | ≥9 ≥7 | |

>6.5-12.5 | ≥195 | |||

>12.5-40.0 | ≥175 | |||

>40.0-80.0 | ≥175 |

Our Services

Payment: by 30%T/T in advance and balance before shipment or 100% L/C at sight

Delivery: within 30 days after we get your deposit or L/C.

Packing: sea worthy wooden pallet

Loading port: Qingdao/Shanghai/Tianjin, China

- Q: This question asks for a comparison between aluminum and other metals, highlighting their distinct properties and characteristics.

- <p>Aluminum is a lightweight, corrosion-resistant metal with a low density, making it ideal for applications requiring strength without excessive weight. It is also a good conductor of heat and electricity. Unlike other metals like iron or copper, aluminum is not magnetic and has a lower melting point. It is also more abundant and cheaper to produce than many other metals, which makes it widely used in industries such as construction, transportation, and packaging. Aluminum's reactivity means it forms a protective oxide layer when exposed to air, which prevents further corrosion. In contrast, metals like stainless steel offer greater strength and resistance to corrosion, while copper has superior electrical conductivity. Each metal has its unique properties that make it suitable for specific applications.</p>

- Q: This question asks about the potential health hazards that can result from exposure to aluminum.

- <p>Aluminum exposure has been associated with several health risks, although the scientific consensus is not entirely clear due to varying study results. Some potential health risks include neurological disorders such as Alzheimer's disease, although this link is still debated. Aluminum may also contribute to bone diseases, as it can interfere with calcium absorption. There are concerns about aluminum's role in kidney dysfunction and possible links to certain types of cancer. However, it's important to note that the human body naturally excretes aluminum, and only a small fraction of ingested aluminum is absorbed. More research is needed to establish definitive links between aluminum exposure and health outcomes.</p>

- Q: Is it possible to utilize aluminum in the creation of innovative battery technologies?

- <p>Yes, aluminum can be used to make new types of batteries. Aluminum-air batteries, for instance, are a type of metal-air battery that uses aluminum as the anode and air as the cathode. These batteries have a high energy density and are lightweight, making them suitable for certain applications like electric vehicles and backup power systems. Research is ongoing to improve the efficiency and lifespan of aluminum-based batteries, addressing issues such as aluminum corrosion and the development of efficient air cathodes.</p>

- Q: What precautions should be taken when using aluminum containers for food and beverages to ensure safety?

- <p>When using aluminum containers for food and drink, safety measures include avoiding prolonged storage of acidic or alkaline foods, as they can cause aluminum leaching. Do not heat aluminum containers in a microwave or expose them to high temperatures, as this can also lead to aluminum release. Regularly inspect containers for signs of wear or damage, as these can increase the risk of contamination. Always use food-grade aluminum containers and avoid using them for non-food items. Washing aluminum containers with mild detergents and avoiding abrasive cleaners can also help maintain their integrity and safety.</p>

- Q: This question asks for a list of negative aspects or drawbacks associated with the use of aluminum.

- <p>Aluminum, while widely used, has several disadvantages. It is non-magnetic and non-conductive, which limits its use in certain applications requiring these properties. Aluminum is also relatively soft and can dent or scratch easily, affecting its durability in some contexts. Additionally, its production process is energy-intensive and contributes to environmental pollution. Furthermore, aluminum can have negative health impacts if ingested in large quantities, potentially leading to neurological disorders. Lastly, aluminum's light weight can be a disadvantage in applications where greater strength or weight is required.</p>

- Q: What are some potential alternative uses for recycled aluminum that haven't been widely considered?

- <p>Recycled aluminum has a wide range of potential uses beyond the common ones like beverage cans and automotive parts. It can be used in the construction of buildings and infrastructure due to its strength and lightness. Additionally, it can be utilized in the aerospace industry for crafting aircraft components, given its resistance to corrosion and fatigue. In the electronics sector, recycled aluminum can be employed in the production of various components, such as circuit boards and casings. Moreover, it can be used in the creation of consumer goods like furniture, as well as in the packaging industry for food and pharmaceutical products. The versatility of recycled aluminum makes it a sustainable choice for many industries, reducing waste and environmental impact.</p>

- Q: What are the typical applications for aluminum sheet metal?

- <p>Aluminum sheets are versatile and have numerous applications due to their lightweight, corrosion resistance, and strength. Some common uses include construction for roofing and siding, automotive parts such as body panels and heat sinks, packaging for food and beverages, aerospace for aircraft components, and in the manufacturing of electronic devices due to its good thermal conductivity. They are also used in signage, furniture, and various decorative applications.</p>

- Q: Is aluminum a material that can be utilized in medical or pharmaceutical applications?

- <p>Yes, aluminum is used in medicine and pharmaceuticals, primarily in the form of aluminum salts. It is used as an adjuvant in vaccines to enhance the body's immune response. Aluminum compounds are also used as antacids to neutralize stomach acid and in some medications as a buffering agent. However, its use is regulated due to potential health concerns, and it's important to note that aluminum is not used in direct contact with the body for extended periods due to its potential toxicity.</p>

- Q: Describe the reaction between aluminum and oxygen, including the product formed.

- <p>Aluminum reacts with oxygen to form aluminum oxide (Al2O3). This reaction is an oxidation process where aluminum loses electrons and oxygen gains them. The reaction can be represented by the equation: 4Al + 3O2 鈫?2Al2O3. Aluminum oxide forms a protective layer on the surface of aluminum, preventing further oxidation. This property makes aluminum a corrosion-resistant metal, despite its reactivity with oxygen.</p>

- Q: This question asks about the impact of using recycled aluminum on the economy and society. It seeks to understand the benefits and consequences of this practice.

- <p>The use of recycled aluminum has significant positive effects on the economy and society. Economically, it reduces the demand for raw materials, lowering costs and conserving natural resources. It also creates jobs in recycling and manufacturing sectors, stimulating economic growth. Environmentally, recycling aluminum saves energy, as it requires only 5% of the energy needed to produce new aluminum from bauxite ore. This reduces greenhouse gas emissions and lessens the environmental impact of mining. Additionally, it helps in waste management by reducing landfill waste, contributing to a cleaner and more sustainable society.</p>

Send your message to us

Aluminum Hot Rolled Coils for Tanker and Trailer Manufacturing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords