Hot-dip Zinc Coating Steel Building Roof Walls -Good Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls -Good Price

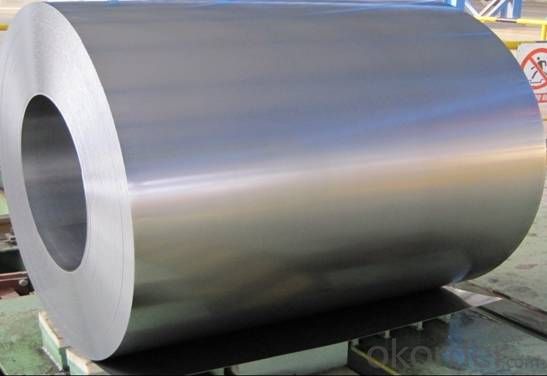

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

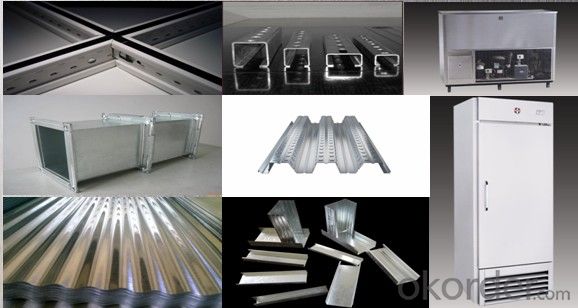

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

3.Hot-Dip Galvanized Steel Sheet Images

4.Hot-Dip Galvanized Steel Sheet Specification

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.18mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

Technology test results:

Processability | Yield strength | Tensile strength | Elongation % | 180°cold-bending |

Common PV | - | 270-500 | - | d=0,intact,no zinc removal |

Mechanical interlocking JY | - | 270-500 | - | d=0,intact,no zinc removal |

Structure JG | >=240 | >=370 | >=18 | d=0,intact,no zinc removal |

Deep drawn SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

EDDQ SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

5.FAQ of Hot-Dip Galvanized Steel Sheet

We have organized several common questions for our clients,may help you sincerely:

1.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: All the steel straps that secure my deck and stair 6x6 posts to the concrete piers have some rust on them. Had bought a rust reducer to spray on them and repaint. As I went to do this I found that one of them is on its last legs, with the steel rusted through and bubbling up all up the sides of the straps. Since this is the end post on a row of 3 deck support posts, I was thinking of removing as much rust as possible, then paint with Rustoleum and cover lower post with something to keep water away from post and pier in the future? Was thinking of something removeable so I could check on it for further rusting. What do you folks with building experience think of this? Thanks.

- Sorry troll, doctors don't give a tetanus shot just because you came into contact with rusty metal. The belief that you need a tetanus shot for stepping on a rusty nail is not quite accurate -- it's not the rust that prompts the shot, it's the fact that the nail was on the ground and dirty.

- Q: How are steel coils inspected for thickness?

- Steel coils are inspected for thickness using a non-destructive testing method called ultrasonic testing. In this process, high-frequency sound waves are transmitted through the coil, and the time it takes for the waves to bounce back is measured. This allows for precise measurement of the thickness of the steel coil, ensuring it meets the required specifications.

- Q: What are the challenges in coil leveling for coated steel?

- Coil leveling for coated steel presents several challenges due to the additional layer of coating. Firstly, the coating can be sensitive to pressure and friction, making it prone to damage during the leveling process. Maintaining the integrity of the coating while achieving the desired flatness of the steel is a delicate balance. Additionally, the thickness of the coating can vary across the coil, leading to uneven leveling results. The choice of leveling equipment and parameters must be carefully determined to minimize coating damage and ensure consistent flatness throughout the coil. Moreover, the presence of coating can impact the accuracy of leveling measurements, as it may interfere with the sensors or affect the readings. These challenges require careful attention and expertise to successfully level coated steel coils while preserving the quality of the coating.

- Q: What are the common surface defects in steel coils?

- Common surface defects in steel coils include scratches, rust, scale, pits, and stains.

- Q: my friend needs sensitive ears....she wants to borrow mine but it says surgical steel,what does that mean?

- It means they are hypoallergenic.

- Q: What are the common problems faced during steel coil production?

- During the production of steel coils, several common issues may arise. One of the most frequently encountered problems is the breakage or damage of the coils. This can happen as a result of improper handling or transportation, leading to cracks or fractures. To minimize the risk of coil breakage, it is crucial to adhere to proper handling procedures. Another issue that often arises is coil slippage. This occurs when the coils are not securely stacked or stored, causing them to shift or slide. Coil slippage can cause damage to the coils and potentially lead to accidents or injuries. Therefore, it is essential to have adequate storage systems in place to prevent such slippage. Furthermore, corrosion is a prevalent problem in steel coil production. Corrosion can be caused by exposure to moisture, air, or other corrosive substances. It can result in the deterioration of the steel, reducing its strength and durability. To address this issue, it is necessary to implement effective corrosion prevention measures, such as proper coating or storage techniques. Coil quality issues are another challenge faced in steel coil production. These problems can include inconsistencies in thickness, width, or surface defects on the coils. Various factors, such as improper rolling processes, equipment malfunctions, or material defects, can contribute to these quality problems. Regular quality checks and inspections should be carried out to promptly identify and resolve any issues. Moreover, problems related to coil handling and loading may also arise during steel coil production. Improper lifting or loading techniques can lead to coil damage, resulting in deformations or even accidents. Proper training and education of employees on appropriate handling and loading procedures are crucial to prevent such problems. In conclusion, steel coil production can encounter various challenges, ranging from coil breakage and slippage to corrosion and quality issues. Implementing proper handling, storage, and quality control measures is indispensable in minimizing these problems and ensuring the production of high-quality steel coils.

- Q: and what are the four main elements in STAINLESS steel? x

- Very high carbon steel (0.96 to 2.11%) is hard and not very ductile (difficult to mold or shape). It is also difficult to weld, but has the lowest melting point. As the carbon content is reduced, the steel becomes softer, more ductile and melts at a higher temperature. Stainless steel is an alloy of Iron, Carbon, Chromium. The fourth element would depend upon the grade of steel, but Nickel is probably the most common.

- Q: for my engineering project I have been asked to design a method of suspending a TV of weight 14Kg from a gantry, the TV must be 5m below the gantry. My team have decided to use as a suspension method a steel cylinder of outer diameter of 10cm and an inner diameter of 8, however we now need to work out both the max stress and strain and the actual stress and strain. and help would be useful

- the area of the cylinder bypass area is extensive actual its 28.26 cm^2 so if the wieght is 14 which ability the metallic consists of .5 kg/cm2 , which isn't something we enable metallic the gentle one carry as much as a million.4 t/cm2 that's 1400 kg no longer 0.5 , so dont worry urself approximately deflection....

- Q: What are the safety considerations when handling steel coils?

- There are several safety considerations that should be taken into account when dealing with steel coils. Firstly, it is crucial to wear the correct personal protective equipment (PPE), such as gloves, safety glasses, and steel-toed boots. This protective gear helps minimize the risk of injuries from sharp edges, flying debris, or accidental contact with the coils. Secondly, it is important to have a clear understanding of the weight and dimensions of the steel coils being handled. Steel coils can be extremely heavy, and improper lifting techniques can lead to back strains, muscle pulls, or even more severe injuries. Therefore, it is crucial to employ proper lifting techniques, such as bending the knees and maintaining a straight back, or using lifting equipment like cranes or forklifts when necessary. Moreover, steel coils can be unstable and susceptible to rolling or shifting during handling. To avoid accidents, it is vital to secure the coils adequately before moving or stacking them. This can be achieved by using appropriate lifting attachments, binding the coils together, or utilizing racks or other storage systems specifically designed for steel coils. Additionally, it is important to be aware of the potential hazards associated with the steel coils, such as sharp edges, oil or grease coatings, or even damage to the coils themselves. It is essential to inspect the coils for any irregularities or defects before handling them, as well as ensuring that they are stored safely and securely to prevent accidents. Lastly, proper communication and training are crucial when dealing with steel coils. Establishing clear channels of communication between workers is essential to ensure that everyone is aware of their roles and responsibilities. Furthermore, providing training on safe handling techniques, potential hazards, and emergency procedures can significantly reduce the risk of accidents and injuries. In conclusion, when handling steel coils, it is important to wear the appropriate PPE, employ proper lifting techniques, secure the coils adequately, be mindful of potential hazards, and ensure effective communication and training. By adhering to these safety considerations, the risk of accidents and injuries can be greatly diminished.

- Q: What is the material of steel coil 08F and what brand can be used instead?

- 20 steel used for various mechanical parts is not subjected to great stress and toughness, such as rod, sleeve, screw, lifting hook; also can be used for manufacturing in 60 pressure and 450 DEG C using non corrosive medium pipes, pipe; can also be used for carbon and cyanide carburized core strength is not the chain, such as bushings, roller, shaft and gear, sprocket and other important.

Send your message to us

Hot-dip Zinc Coating Steel Building Roof Walls -Good Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords