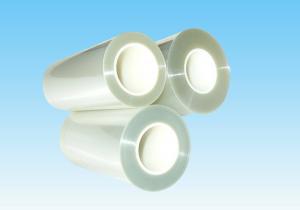

High Temperature Clear / Transparent Stretch Film for Food Packaging

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1*20'FCL m²

- Supply Capability:

- 400000 Square Meters per Day m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Application of Release Film:

Release film is widely used in waterproofing industry, it has a good feature for waterproof and moisture proof, so it is mainly used as the surface material for waterproof membrane. We can also provide other types of release film that can be used in disposable personal healthcare products and disposable medical protection products.

Technical Data of Release Film:

|

Material |

PE |

|

Gsm |

15-80 |

|

Density |

0.941~0.960 |

|

Colour |

White, blue, pink and any common color |

|

Width |

50-2100MM |

|

Roll diameter |

As per customer request |

|

Major ingredient |

PE and filler |

|

5% Tensile force at break point g/inch |

MD>200,CD>200 |

|

Tensile force at break point g/inch |

MD>800,CD>600 |

|

Elongation(%) |

MD>200,CD>300 |

|

Heat resistance (%) |

Vertical<5 |

|

Technology |

Casting |

|

Extinction treatment |

Treated |

Package of Release Film:

Paper tube: 10cm, Carton measure:45*45*(product width+1.5)cm

15tons/20GP with carton packing

- Q: What is the impact of TPO waterproofing membrane welding performance?

- Factors affecting the welding performance of TPO coil mainly in the following areas: 1. Material melting point and welding window;

- Q: Waterproof electrode, waterproof welding

- 4, the first weld after the end of the weld there are a variety of defects. Such as: welding only in the wall surface, there is no penetration, welding weld when the inclusions and welding overflow quenching and melting of molten metal and so on. These defects in the original weld even if the re-welding, can not achieve the desired results. Therefore, in order to ensure the strength of the weld, should be added in the welding ribs, plate

- Q: Surfacing isolation layer is the application of what, how to achieve surfacing isolation layer weld.

- Surfacing as a material surface modification of an economical and rapid process, more and more widely used in various industrial sector parts manufacturing repair.

Send your message to us

High Temperature Clear / Transparent Stretch Film for Food Packaging

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1*20'FCL m²

- Supply Capability:

- 400000 Square Meters per Day m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords