High Speed Cone Rewinder Machine for Rewinding Yarn

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Main Structure of High Speed Cone Rewinder Machine:

Shafting: vertical tensioner & waxing unit

Creel pressure balance device:Ni-P alloy grooved drum & motor

Single spindle controller: The transverse regulating system

Automatic tube filling machine:the conveyor of tubes

Description of High Speed Cone Rewinder Machine:

High Speed Cone Rewinder Machine is used for winding yarns on cones.

Application:

High Speed Cone Rewinder Machine is suitable for processing PP, PE split film yarn/ just twine, cotton twine, weaved twine to ball.

Main Features:

High Speed Cone Rewinder Machine has the following advantages:

· Vertical winder path with no inflection,little friction and less hairiness.

· Converient to adjust the speed of single spindle. It can provide different winding speed for various yarns.

· Double points waxing system with micro motors, waxing steady and uniform. The forming of cheese is better.

Using high quality alloy drums with optimized groove shape ,which has the advantages of good anti-overlapping characteristics, light weight,good wear resistance, and static elimination.

Single winding motor control for each spindle, single spindle automatic stop while yarn breaking or fully filled.

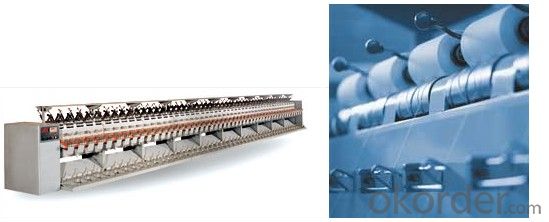

Images of High Speed Cone Rewinder Machine:

Specification:

| Items | Technical parameters |

| Types of winding | Drum,Random |

| Mechanical speed | Up to 1200m/min (process speed depending on quality of yarn and feed packages) |

| Package shape | Cylindrical or conical packages |

| Traverse length | 147mm,150mm,154mm |

| External dimensions | 13410mm(length) ×700mm(width) ×1680mm(height) |

| Power supply | 3 phased 380V±10% ,50/60HZ |

| Automatic length fixing | Automatic length fixing,max:999999m |

FAQ of High Speed Cone Rewinder Machine:

· Q:What is the machine used for?

A:Vertical Soft Yarn Winder is suitable for processing PP, PE split film yarn/ just twine, cotton twine, weaved twine to ball.

· Q: What is the MOQ?

A: 1 set.

· Q: What is the lead time of the product?

A: 5-20 days after payment

- Q: What is the difference between yarn spinning and ring spinning?

- Air spinning without spindle, mainly by the carding roller, spinning cup, false twist device and other components. The carding roller is used to grasp and card the fed sliver fiber, and the centrifugal force produced by his high-speed rotation can throw the captured fiber. Spinning cup is a small metal cup, his rotation speed than the carding roller more than 10 times higher, resulting in the centrifugal effect, the cup of air to the row;

- Q: When the textile industry, as well as the history of the textile industry development?

- Ancient countries in the world for the textile fibers are natural fibers, usually wool, linen, cotton) three short fibers, such as the Mediterranean region before the textile fiber is only wool and linen; India Peninsula region before the use of cotton

- Q: What are the different effects of textile equipment?

- Overall, China's textile industry is a labor-intensive industries, the threshold is low

- Q: Textile equipment to protect the work is not a special type of work?

- , In accordance with the current social insurance policy, special types of early retirement must also have four conditions: First, engaged in special types of work must be the former Ministry of Labor and the central authorities approved the special types of work, different industries between the special types of work Can not match each other. Second, must be in the original state-owned, collective enterprises engaged in high-altitude and particularly heavy manual labor accumulated over 10 years; engaged in underground, high temperature work accumulated over 9 years; engaged in other toxic and harmful work accumulated over 8 years. Third, the staff file on its special trades experience in the original record. Four men over 55 years of age, women over 45 years of age, and the cumulative payment of 15 years of years.

- Q: What is the chenille mechanical principle?

- Its production and processing products called chenille yarn or spiral, broken wire, is a new variety of fancy

- Q: What are the risks of safety accidents in the textile machinery industry?

- Textile machinery industry is the light industry, mainly to master with high-speed rotating machine production

- Q: Who invented Jenny spinning machine?

- 1768 J. Hargreaves in Nottingham joint venture with others to start a spinning workshop, with Jenny spinning machine production of knitted yarn. Because he did not apply for a patent, so only their own production "Jenny machine" to make money. "Jenny machine" is not only efficient, and the quality of spinning yarn is also better, so Hargreaves business is good, "Jenny machine" is also gradually spread out.

- Q: What are the mechanical characteristics of textile machinery?

- High efficiency, high efficiency, provincial maintenance; standardization, serialization, generalization; low energy consumption, low noise, low pollution, is the characteristics and direction of modern textile machinery.

- Q: What is the historical background of the mechanization of the British cotton textile industry?

- Social environment: the completion of the bourgeois revolution, the British domestic social stability.

- Q: What is the structure and working principle of Jenny's spinning machine?

- Stretch the yarn by hand while twisting it. After the completion of the stop or a small reversal of a large wheel, the yarn from the hook out, and then turn the wheel, reducing the tensile strength of the hands, cotton yarn on the winding to the spindle.

Send your message to us

High Speed Cone Rewinder Machine for Rewinding Yarn

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords