High Quality Construction hoist Building Hoist SC120

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

High Quality Construction hoist Building Hoist

Descriptions of our building hoist:

The general building hoist manufactured by our company have the features as good quality, long life, wide application range and convenient for maintenance, the gering adopts imported bearing, enameled cable, and oil seal, the electric parts adopt products from world renowned manufactures such as Schneider, Siemens, and LG, the racks and pinion adopts special material and heat-treatment technique, which prolong the life of these parts. The steel structure uses quality steel from famous domestic manufacturers, the surface of the structure can apply paint-spray, Parkerizing baking finish or hot galvanizing processing according to users requirements, the cage can be produced and decorated by aluminum molded board, punched-plate or figured aluminum board.

Main Features of Building Material Hoist

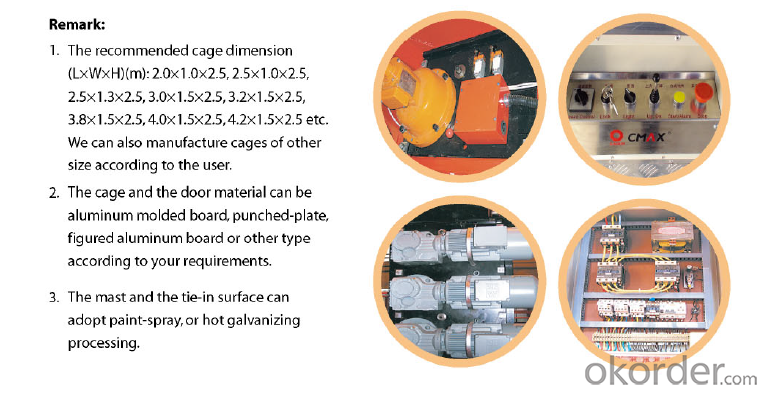

1. the recommended cage dimension(LXWXH):2.0X1.0X2.5, 2.5X1.0X2.5, 2.5X1.3X2.5, 3.0X1.5X2.5, 3.2X1.5X2.5, 3.8X1.5X2.5, 4.0X1.5X2.5, 4.2X1.5X2.5 etc, we can also manufacture cages of other size according to the user.

2. The cage and the door material can be aluminum molded board, punched-plate, figured aluminum board or other type according to your requirements.

3. The mast and the tie-in surface can adopt paint-spray, or hot galvanizeing processing.

Advantage of our building hoist:

1. Our own systems of production engineering.

2. Production design from the concept to the engineering details.

3. Technical experts with great experience in the sector.

4. Continuous development of new solutions and products adapted to the requirements of our clients.

5. Methodology and project procedure administration in compliance with current guidelines.

6. Extensive worldwide commercial network

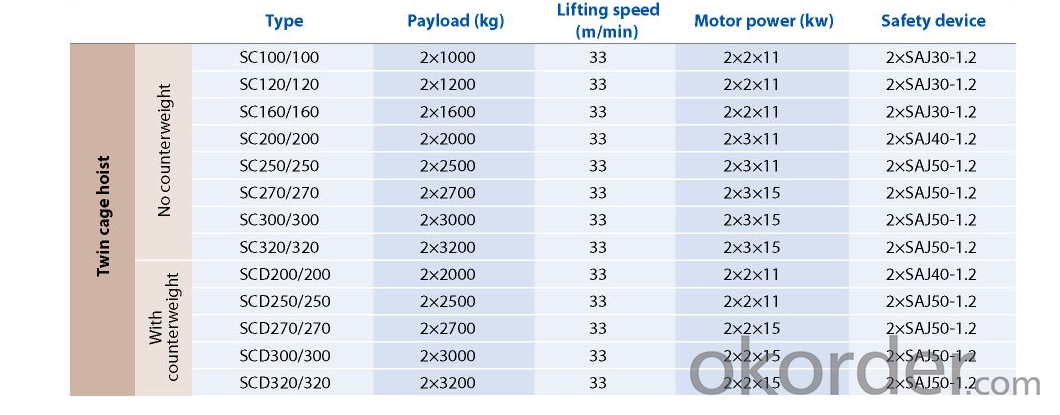

Specification of our building hoist:

1. why chose us?

China National Building Materials (Group) Corporation (CNBM), established in 1984,now is one of the largest state-owned group corporation in China, dealing with building materials & industrial equipment. Up to year 2010, CNBM Group's total asset is 20 billion USD and total staff is more than 100,000.CNBM International Corporation, specializes in designing & manufacturing of various

kinds of construction machinery, including tower crane, building hoist, etc. All the equipment produced by CNBM are compliant with the National level quality standard, and wins great reputation for their endurable performance in worldwide markets.

2.How about the shipment?

You can put 2 sets of of wheel loaders in one 40HQ container. The spare parts are packed with boxes.

The delivery time is 20 days.

3. What about your service?

We have our factory, we can meet customers needs as soon as possible.

We have first rate professional technology and provide good after-sales service.

4.After Sales Service

We offer the Preventative Maintenance and After Sales Service. For we strongly feels about the importance of supporting our customers and the product solutions we provide. Consequently we offer comprehensive maintenance options to prevent equipment issues before they become problems. Also we offer one year guarantee period.

Advantages

1 sincere

CNBM International is a state company, now is one of the largest state-owned group cooperation in China! All the outdoor heaters produced by CNBM are compliant with the national level quality.

2 professional

Our engineers will at your services 24hours to answer your questions. Our goal is to provide the best professional services.

3 quality

CNBM International’s outdoor heater have strict quality control, only the best quality products can pass the test.

4speed

We have professional sales team to guarantee your reply within 12hours to save your precious time.

5 After sales

If the tower crane has any problems, we will solve your problems in first time.

- Q: This question asks for a guide on how to change the tightness of the ropes on a construction hoist.

- <p>Adjusting the tension on a building hoist involves several steps. First, ensure the hoist is powered off and secured to prevent any movement. Locate the rope tensioning mechanism, often found at the base or top of the hoist. This could be a ratchet system, a spring-loaded mechanism, or a manual adjustment bolt. For ratchet systems, adjust the tension by turning the ratchet handle to tighten or loosen the rope. For spring-loaded mechanisms, adjust the spring tension by turning the adjustment bolt. Ensure the rope is properly seated in the pulley system and not frayed or damaged. After adjusting, test the hoist with a small load to ensure the tension is appropriate and the hoist operates smoothly. Always refer to the manufacturer's manual for specific instructions and safety precautions.</p>

- Q: Is it possible to use a lifting device to assist in lifting a person who is too heavy to lift manually?

- <p>Yes, lifting devices such as hoists or mechanical lifts can be used to safely lift someone who is too heavy to lift manually. These devices are designed to support the weight and reduce the risk of injury to both the person being lifted and the caregiver. It's important to use the appropriate equipment for the individual's weight and to follow safety guidelines and manufacturer's instructions to ensure proper and secure lifting.</p>

- Q: Can construction elevators be taken by people or by goods

- ?yes, you can! It is to pass the authority authority to issue use card to be able to use! Construction lifts are also called elevators

- Q: This question asks for a description of the process of operating a building hoist using a remote control system.

- <p>To use a remote control system for a building hoist, first ensure that the hoist is properly installed and inspected for safety. Turn on the hoist's power supply and ensure the remote control is synced with the hoist. Familiarize yourself with the control panel, which typically includes buttons for up, down, stop, and emergency stop. Operate the hoist by pressing the up or down buttons to lift or lower the load. Always monitor the load's movement and communicate with workers on site. Use the stop button to halt the hoist if needed, and the emergency stop button in case of an immediate hazard. Regularly check the hoist's operation and maintain the remote control system to ensure smooth and safe operation.</p>

- Q: This question asks for examples of typical uses for building hoists, which are devices used to lift materials in construction settings.

- <p>Building hoists are commonly used in various construction applications. They are utilized for lifting and lowering materials and personnel in high-rise construction projects. Some examples include: 1) Lifting building materials such as bricks, cement, and steel beams to different floors of a building under construction. 2) Transporting workers to elevated work areas for tasks like scaffolding assembly or window installation. 3) Moving heavy equipment to upper levels of a structure. 4) Assisting in the installation of large fixtures like HVAC systems or electrical wiring systems. 5) Facilitating the removal of construction waste from upper floors. These applications highlight the versatility and efficiency of building hoists in construction projects.</p>

- Q: What are the primary materials and components typically utilized in the construction of building hoists?

- <p>Building hoists, also known as construction hoists, are typically made from a combination of steel, aluminum, and sometimes plastic. The frame and main structure are usually constructed from steel for strength and durability. Aluminum is often used for components like the platform and railing due to its lightweight properties, which can reduce the overall weight of the hoist. Plastic components may be used for certain parts to enhance resistance to weather and corrosion. Additionally, hoists may incorporate electrical and mechanical systems, which include cables, gears, and motors, to facilitate the hoisting and lowering of materials and personnel.</p>

- Q: Is it possible for a single lifting device to simultaneously lift multiple objects with varying weights?

- <p>Yes, a single lifting device can be used to lift multiple objects at once with different weights, provided the total weight does not exceed the device's lifting capacity. The device must be designed to handle the combined weight and ensure even distribution of the load. Safety measures and proper securing of the objects are crucial to prevent accidents. It's important to follow the manufacturer's guidelines and never exceed the maximum load capacity to avoid damage or injury.</p>

- Q: The construction elevator should have those procedures

- Installation and demolition plan, content can guide safe construction, and have complete approval procedure. The installation and demolition of the team must hold the certificate of safety of the above provincial competent authorities. There should be substantial content for the safety of the installation, the demolition of the staff and the safety technology of the driver. Should have basic design, hidden acceptance and concrete strength speech. The inspection and acceptance of the installation completed and the inspection presentation of the competent part. The construction elevator has a record. The elevator is using a copy of the original copy. An employee's special course post certificate. Other relevant safety information. The construction elevator is a larger vertical transport equipment, and the safety and blood lessons of previous accidents are profound. Strict inspection, the key prevention of elevator accidents, is the key link of the safety management at the construction site, and the safety management staff at all levels should be awake and familiar.

- Q: This question asks for safety precautions that should be taken when using a building hoist, which is a type of lifting equipment used in construction.

- <p>Safety measures for using a building hoist include regular inspections and maintenance, ensuring all safety devices are in good working order, securing all loads properly, and not overloading the hoist. Operators must be trained and certified. Protective barriers should be in place to prevent unauthorized access. Emergency stop switches should be readily accessible. Workers should wear appropriate personal protective equipment, and communication between the hoist operator and those on the ground should be clear and effective. Adhering to these measures helps prevent accidents and ensures the safe operation of the building hoist.</p>

- Q: This question asks for a comparison of the benefits and drawbacks associated with the use of hydraulic lifting equipment.

- <p>Hydraulic lifting equipment offers several advantages, including high force generation, compact design, and precise control. It is energy-efficient and can handle heavy loads with ease. The systems are also known for their durability and low maintenance requirements. However, there are disadvantages such as sensitivity to leaks and the need for regular fluid checks. They can be complex to install and maintain, and the equipment can be costly. Additionally, hydraulic systems are sensitive to temperature changes, which can affect performance.</p>

Send your message to us

High Quality Construction hoist Building Hoist SC120

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords