High Quality and Good Price Grinding Rod with Dia 30mm-300mm Used in Rod Mill

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 150,000M.T. m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Quality and Good Price Grinding Rod with Dia 35mm-140mm Used in Rod Mill

1. Specifications of High Quality and Good Price Grinding Rod with Dia 35mm-140mm Used in Rod Mill

Diameter: 30mm--300mm, or as customer's requirement

Length:2m-12m, or as customer's requirement

Application: mainly used in the rod mill. The detailed fields are: Mining Ores, Cement, Chemical Factory, Coal-powered plant,quartzs and so on.

Package: By bundle, or as customer's requirement

2.Chemical Composition of High Quality and Good Price Grinding Rod with Dia 35mm-140mm Used in Rod Mill

Material | C | Si | Mn | Cr | Cu | Mo | P | S |

45# | 0.42-0.50 | 0.17-0.37 | 0.5-0.8 | 0.25 | 0.25 | 0.3 | | |

50Mn | 0.48-0.56 | 0.17-0.37 | 0.7-1.0 | 0.25 | 0.25 | 0.3 | | |

60Mn | 0.57-0.65 | 0.17-0.37 | 0.7-1.0 | 0.25 | 0.25 | 0.3 | | |

65Mn | 0.62-0.70 | 0.17-0.37 | 0.9-1.0 | 0.25 | 0.25 | 0.3 | | |

RCBA-1 | 0.52-0.65 | 0.17-0.37 | 0.6-1.2 | ≤0.25 | | | ≤0.035 | ≤0.035 |

RCBA-2 | 0.5-0.8 | 0.17-0.37 | 0.6-0.8 | 0.9-1.1 | | | ≤0.035 | ≤0.035 |

RCBA-3 | 0.72-0.92 | 0.17-0.37 | 0.7-1.0 | 0.5-0.9 | | | ≤0.035 | ≤0.035 |

3.Properties and Microstructure of High Quality and Good Price Grinding Rod with Dia 35mm-140mm Used in Rod Mill

material | diameter | length | hardness | metallurgical structure |

45# | 30-300mm | 2-12m | ≥45 | M+C |

50Mn | 30-300mm | 2-12m | ≥50 | M+C |

60Mn | 30-300mm | 2-12m | ≥55 | M+C |

65Mn | 30-300mm | 2-12m | ≥55 | M+C |

RCBA-1 | 30-300mm | 2-12m | ≥50 | M+C |

RCBA-2 | 30-300mm | 2-12m | ≥55 | M+C |

RCBA-3 | 30-300mm | 2-12m | ≥55 | M+C |

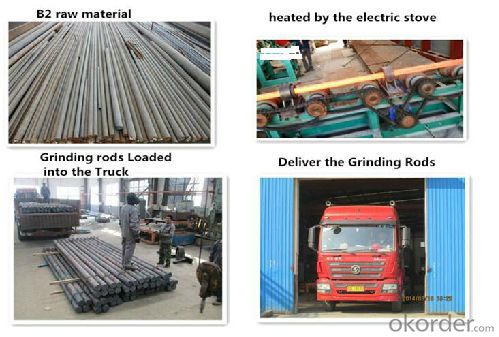

4.Production Process of High Quality and Good Price Grinding Rod with Dia 35mm-140mm Used in Rod Mill

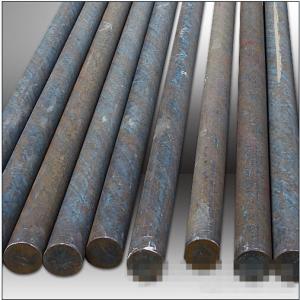

5.Some Photos of High Quality and Good Price Grinding Rod with Dia 35mm-140mm Used in Rod Mill

- Q: What are the casting parts used to test shrinkage holes?

- 1. anatomy. It is easy to slack off by sawing and machining.

- Q: Domestic large steel castings factory which is better, recommend!

- At least spend money on research and development, then the quality should be all right.

- Q: the parts of the threaded hole is casting, casting the hole directly, and then tapping or casting, and then punch 10When the casting is ready, punch it again before tapping it Is the hole casting good or is it punched and tapped on the drilling machine after casting?

- There are several casesThe first hole with a diameter of less than 4MM is generally not done, or as a hole location only for a period of less than 10MM.Second for the big hole, some of the reasons for the holding force, we must increase the slope, direct tapping is unlikely, so it still needs post-processingThird for products with high tightness requirements, some cores need to be made even if they are very small, so they can be tapped directlyFourth, some due to technical requirements, regardless of the size of each other's requirements must be made, there is no wayThe above methods are common, and they will encounter many small problems in actual production.

- Q: Does anyone know how to make precise casting parts for aerospace or manufacturers of single and small quantities of automotive parts and components, mainly in Beijing, Tianjin and Tangshan?

- List of China's military enterprises list of ten major military groupsChina Nuclear Industry Construction Group CorporationChina Aerospace Science and Technology CorporationChina Aerospace Science and Engineering CorporationChina Aviation Industry CorporationChina Aviation Industry Corporation IiChina State Shipbuilding CorporationcsicChina North Industries Group CorporationChina South Industries Group CorporationChina National Nuclear CorporationKey military enterprisesShipbuilding industry:China State Shipbuilding Corporation (South ship group), (China Shipping Group)China Shipbuilding Industry Corp (North Ship group), (China Shipbuilding Industry)Guangzhou Shipyard International Limited by Share Ltd (GSI)Jiangnan Heavy Industry Limited by Share Ltd (Jiangnan Heavy Industry)Nuclear industry:China National Nuclear Corporation (CNNC)China Nuclear Industry Construction Group Corporation

- Q: How can the casting be quenched and tempered?

- Cast steel annealing or normalizing parts in strength and toughness is insufficient, can be used in quenching and tempering treatment. It is mainly used for gear, gear and other parts of the cast steel. The conditioning has two kinds: one kind is cast directly after quenching and tempering, with warm water (40---50 degrees) intermittent cooling, suitable for ZG270---500, ZG310----570 and other castings.

- Q: As shown, how do I achieve the tightness test of this product, and achieve industrial production? Seek expert advice.

- Precise and tight sealing of the surface to which the test piece is to be tested, equipped with an airtight test instrument, and an electrical control system. You can complete automated testing equipment

- Q: My parts complex, machining costs are relatively high, so want to cast, but the surface needs anodizing, what material will be better?

- The common material that can be anodized is aluminum alloy. It is recommended to use casting aluminum alloys, such as ZL102 and ZL105, which are commonly used as cast aluminium alloys. The processing of aluminum casting is easy. After processing, the surface of the whole part can be anodized. The color can be chosen.

- Q: Why should pig iron be used in casting?

- Popular name is called pig iron, in fact, is a kind of cast iron without treatment, after casting, in iron elements to add other elements to improve casting performanceIt mainly improves the fluidity, reduces the melting point and reduces the shrinkage.Usually pure iron and cast iron at the eutectic point (about 4.7% carbon content) can be used for castingThere are many kinds of cast iron, usually grey cast iron, ductile iron and vermicular graphite iron......

- Q: What foundry factories are used in the casting parts of China's major automobile manufacturers?

- For example Changchun FAW, under a casting, two casting and other casting plant, but there are more than half of all outsourcing in Tianjin Hebei Shandong purchase, many automobile enterprises to casting foundry.

- Q: Which master knows how the casting tolerances for malleable iron, gray iron and ductile iron should be chosen? Hurry up, thank youCan you provide a tolerance scale for castings, please?

- Usually manual molding optional CT11 class, ordinary machine modeling optional CT10 class, high pressure molding should reach CT9 level. The tolerances on the wall thickness of the casting are comparable to those of other dimensions of the same casting.

1. Manufacturer Overview

| Location | Zhangqiu, China |

| Year Established | 1995 |

| Annual Output Value | 150,000M.T. |

| Main Markets | 40%,South America; 30%,South Africa; 15%,Southeast Asia; 5%, Europe Area; 5%, North America; 5%, Other Areas |

| Company Certifications | ISO9001:2008;SGS Test Report |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao;Tianjin |

| Export Percentage | |

| No.of Employees in Trade Department | 25 |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 68,000m2 |

| No. of Production Lines | 15 |

| Contract Manufacturing | |

| Product Price Range | $700/M.T.-$1200/M.T. |

Send your message to us

High Quality and Good Price Grinding Rod with Dia 30mm-300mm Used in Rod Mill

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 150,000M.T. m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords