High Quality Adhesive Closed Cell Foam with Aluminum Foil Facing

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

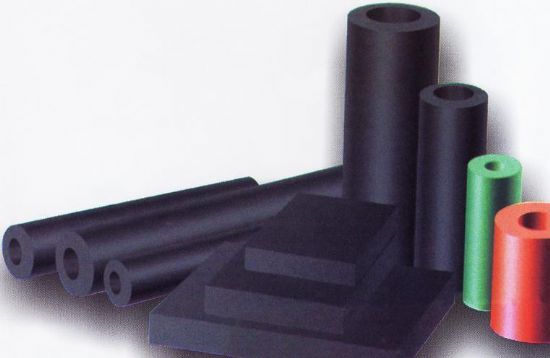

Flexible Rubber Plastic Insulation Material

Adhesive Closed Cell Foam High Quality

rubber plastic is a high quality heat-insulating and heat-preservation material which use butyronitrile rubber and polyvinychloride(NBR,PVC) as main raw materials.

The productionprocess includes mixing, tensing and continuous extruding , heating andfoaming, cooling and cutting.

FEATURES

Lower heat-conductivity

Higher fire-blockingperformance

Damp-proof andWater-proof

Softness

Neat and

Easy to installeasy handing and storage

Good flexibilityand tenacity

RUBBER PLASTIC SHEET

Standard Size

Density(kg/m3) | 40-90 | ||||

Thickness(mm) | 10 mm | 15 mm | 20 mm | 25 mm | 30 mm |

Length (m) | 20 | 20 | 10 | 10 | 10 |

Width (m) | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

Remark: Othersized are available upon request. Other colors are available at customers request.

Application

rubber plastic arewidely used in sound isolation of wall planking, sound absorption in air ducts,and sound absorbing decorations in entertainment spaces. It can also be usedfor shock resistance and pressure relief in instruments and equipment.

TechnicalParameters

Item | Specification | Standard |

Density(kg/m3) | 40-90 | GB/T 6343 |

Temperature(℃) | -40~110 | GB/T 17794 |

Flammability | Class B | GB/T 8624-2006 |

Class 0 | BS 476Part7∝Part6 | |

Oxygen index (%) | ≥40 | GB/T 2406 |

SDR | ≤65 | GB/T8627-1999 |

Conductivity factor Average temperature | ≤0.031 | GB/T 10294 |

Water vapor permeability (%) | ≥1.0x104 | GB/T 17146-1997 |

≤1.96x 10-11 | ||

Water absorption ratio in vacuum (%) | ≤10 | GB/T 17794-2008 |

Dimension stability(N/cm) | ≤10 | GB/T 8811 |

Crack resistance | ≥2.5 | GB/T 10808 |

Compression resilience ratio (%) | ≥70 | GB/T 6669 |

Anti-ozone | No cracking | GB/T 7762 |

Ageing-resistance | Slightly crumpling, no cracks no pin holes, not deforming | GB/T 16259 |

Packaging,

Product is packedin cartoon.

RUBBER PLASTIC PIPE

Productintroduction

rubber plastic ismainly applicable to heat insulation of central air-conditioner system,refrigerator room and pipes of all kinds of refrigeration equipment and heatingequipment.

Standard Size

Copper tube OD inch | Seamless tube OD mm | Galvanized tube DN | ID mm | 9mm Nominal thickness | 15mm Nominal thickness | 20mm Nominal thickness | 25mm Nominal thickness | 30mm Nominal thickness | |||||

mm×mm | piece | mm×mm | piece | mm×mm | piece | mm×mm | piece | mm×mm | piece | ||||

1/4 |

|

| 6 | 6×9 | 180 |

|

|

|

|

|

|

|

|

3/8 |

| 6 | 10 | 10×9 | 140 | 10×15 | 80 | 10×20 | 70 |

|

|

|

|

1/2 |

|

| 13 | 13×9 | 120 | 13×15 | 80 | 13×20 | 50 | <p style="background-color:white;background-position:initial initial;background-repeat:initial initial;text-align:lef | |||

- Q: Is it possible to use aluminum foil with a reflective surface for storing fruits and vegetables?

- <p>Aluminum foil facing can be used for storing fruits and vegetables, but it's not the best choice. Aluminum foil is not breathable and can cause condensation, leading to spoilage. It's better to use perforated or micro-perforated films that allow for air exchange while keeping light and moisture out. These films help maintain the freshness of produce by slowing down the respiration process and reducing water loss.</p>

- Q: How should aluminum foil be stored when not in use to maintain its facing orientation?

- <p>The best way to store aluminum foil is to keep it in its original box or a resealable container with the shiny side facing outward. This prevents the foil from sticking together and makes it easier to use. If the box is not available, you can also use a rubber band to wrap the foil around a cardboard tube, ensuring the shiny side is facing out, or place it in a container with a paper towel on the bottom to prevent sticking.</p>

- Q: What are the various uses of aluminum foil facing across different sectors?

- <p>Aluminum foil facing is widely used across various industries due to its properties such as heat resistance, moisture barrier, and durability. In construction, it's used for insulation and moisture protection in walls and roofs. In the food industry, it's essential for packaging to preserve freshness and extend shelf life. In the automotive sector, it's used for heat shielding and soundproofing. Additionally, it's utilized in aerospace for lightweighting and heat protection, and in pharmaceuticals for blister packaging. Its versatility makes it indispensable in many manufacturing processes and product applications.</p>

- Q: This question asks for the most effective method to smooth out wrinkles in aluminum foil facing material.

- <p>The best way to remove wrinkles from aluminum foil facing is to use a combination of heat and gentle stretching. First, preheat your iron on a low setting without steam. Place a thin cloth or parchment paper over the wrinkled aluminum foil facing to protect it from direct heat. Then, gently press the iron over the cloth, moving in a smooth, continuous motion. As the foil warms, it will become more pliable, allowing you to gently stretch and smooth out the wrinkles. Be cautious not to apply too much pressure or heat, as this can damage the foil.</p>

- Q: Is it safe to use recycled aluminum foil as a facing material in cooking?

- <p>No, it is not recommended to use recycled aluminum foil for cooking. Recycled aluminum foil may contain impurities, contaminants, or have been exposed to chemicals that could be harmful when heated. Additionally, the quality and safety of recycled materials are often not as strictly controlled as new materials, which could lead to potential health risks. It's always best to use new, high-quality aluminum foil for cooking to ensure food safety and hygiene.</p>

- Q: Is it safe to use aluminum foil as a liner in a slow cooker, and are there any potential risks or benefits?

- <p>Using aluminum foil as a facing in a slow cooker is generally safe. It can help with easy cleanup and may distribute heat evenly. However, it's important to ensure that the foil doesn't touch the heating element, as this can cause damage to both the foil and the slow cooker. Additionally, while aluminum foil is non-toxic and generally safe, there are concerns about potential leaching of aluminum into food, especially with acidic foods. For health-conscious individuals, using a slow cooker liner made from materials like silicone or stainless steel might be a better alternative.</p>

- Q: Is it safe or practical to use aluminum foil facing as a material for making soup?

- <p>No, it is not advisable to use aluminum foil facing for making soup. Aluminum foil is not designed for direct contact with food, especially when heated, as it can potentially leach aluminum into the food. Additionally, aluminum foil is not a suitable material for cooking vessels as it can tear or puncture easily, leading to safety hazards. Instead, use materials specifically designed for cooking, such as stainless steel, ceramic, or glass cookware, which are safe and non-reactive with food.</p>

- Q: What are the considerations or safety measures to be aware of when using aluminum foil with a nonstick coating?

- <p>When using aluminum foil with a nonstick coating, it's important to avoid exposing it to high heat as the nonstick layer can degrade and release harmful fumes. Do not use it in broilers, on grills, or in the oven at temperatures exceeding 400掳F (204掳C). Additionally, refrain from cutting or puncturing the foil, as this can damage the nonstick surface. Avoid using metal utensils that might scratch the coating. Always follow the manufacturer's guidelines for safe use and temperature limits.</p>

- Q: This question asks for a comparison between aluminum foil facing and other types of metal foil facing, focusing on their differences.

- <p>Aluminum foil facing is distinct from other metal foil facings due to its unique properties. It is lightweight, highly reflective, and offers excellent heat resistance. It's also non-toxic and has good barrier properties against oxygen and moisture, making it ideal for food packaging and insulation. Other metal foils, such as copper or stainless steel, may have different thermal or electrical conductivity properties, and are often heavier and less flexible. Copper, for instance, has higher electrical conductivity but is less common in foil applications due to cost and weight. Stainless steel foils are more durable and corrosion-resistant but are not as reflective or lightweight as aluminum. Each type of metal foil has specific applications based on its unique characteristics.</p>

- Q: What are the particular criteria or considerations when choosing aluminum foil facing materials?

- <p>When selecting aluminum foil facing, specific requirements include the foil's thickness, which affects durability and insulation properties; surface finish, which can impact heat reflection and aesthetics; and the type of adhesive used for bonding, which should be resistant to heat and moisture. Additionally, the foil should have good barrier properties to prevent moisture and air infiltration, and it should be compatible with the substrate materials to ensure a strong bond. Compliance with safety and environmental standards is also crucial.</p>

Send your message to us

High Quality Adhesive Closed Cell Foam with Aluminum Foil Facing

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords