High Pressure Flexiable Rubber Fuel Hose

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: | Hebei, China (Mainland) | Brand Name: | CMAX | Model Number: | R13 |

Name: | R13 rubber & Hydraulic Hose | Material: | rubber & steel wire | Inner tube: | Nitrile |

Cover: | Black neoprene blend | Reinforcement: | four , six spiralled of high-tensile steel wire | Color: | Black/Red/Green/Yellow |

Temperature range: | -40°Fto 212°F(-40°C-100°C) | Applicable standards: | GB/T 10544 R13, EN 856 R13, SAE J517 R13 | Application: | Used for petroleum and Watrer-based hydraulic fluids |

Factory or not: | Factory |

Packaging & Delivery

Packaging Details: | Spiral hose Plastic packing or according to the customer's requirement |

Delivery Detail: | usually 5-30 days. |

High Pressure/coal/oil Hydraulic Hose

Product Description

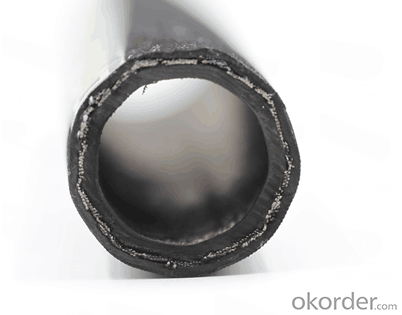

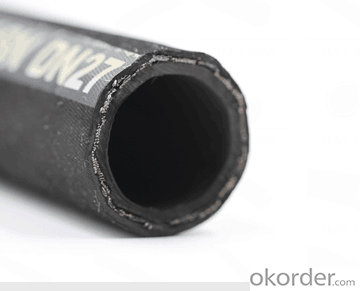

Structure

The hydraulic hose consists of an inner tube of liquid resistant synthetic rubber, middle rubber layer, four layers spiral wire reinforcement, and superior weather resistant synthetic rubber cover.

1. Inner Tube: Neoprene

2. Reinforcement: four or six alternating layeers of spiral high tensile steel wire

3. Cover: Black neoprene blend that meets MT98 and GB/T 15907 Flame resistance

4. Application Standards: GB/T 10544 R13, EN 856 R13, MT98 R13.

Application

hydraulic hose is a medium pressure hose that can be used in mobile, machine tool, agricultural application and other hydraulic systems.

It can also be used in conveying petroleum or water based hydraulic fluids which under specific pressure and temperature.

Working Temperature : Oil: -40°C to +100°C, Air: -30°C to 50°C, Water Emulsion under +80°C

Features

1. It provides superior oil resistance, heat resistance and aging resistance by using special synthetic rubber.

2. It provides high pressure resistance and superior impulse resistance.

3. It provides superior bonding in hose internal, soft use and small deformation under pressure.

4. It provides superior kink resistance and fatigue resistance and longer services life.

FAQ

Q1. Do you produce smooth or cloth wrapped cover?

1. A. Both, we can produce both cover, which depends on customer’s request.

Q2. Do you produce embossed marking?

1. A. Yes, we do provide embossed and printing markings with different color.

Q3. Can you produce product with my own brand?

1. A. Yes, we have been offering OEM services for 20 years.

Q4. Does your product have different color hose?

1. A. Yes, we currently provide black, grey, red, blue and yellow.

Q5. How long does my order take to be delivered?

1. A. It usually takes 5 to 30 days, which generally depends on the quantity of your order and our storage.

- Q: What is the difference between the precast beam of the bridge and the method of pulling out the rubber tube after pouring the concrete? What's the difference between design and calculation?

- Corrugated pipe is included in the design of the amount of engineering, the role is: reserved strand space. Its length is calculated when the work length of the steel strand.

- Q: The basement of submersible sewage pump outlet pipe installation need and flexible rubber joint is not installed? Can not?

- Rubber joint, also called shock proof throat, is mainly used in the entrance and exit of pumps. It is used to absorb the noise caused by vibration during the operation of pumps.

- Q: What do you mean by "DN" on hydraulic hose?

- Hydraulic hose is mainly composed of liquid synthetic rubber, inner rubber layer, middle rubber layer, multi-layer reinforced layer and weather resistant synthetic rubber outer layer. The utility model is mainly used for hydraulic support and oil field development of a mine, and is suitable for engineering, construction, hoisting, transportation and automation hydraulic system to transport medium and water base fluid with certain pressure and temperature.

- Q: What should I pay attention to when rubber tube is in storage?

- Storage should be as follows: (1) should be stored in a ventilated and dry environment, the relative humidity of the air is 50% ~ 80%. (2) should be stored in non corrosive media, and away from the heat source, the temperature is about 5 degrees Celsius conditions. (3) packing should be kept as far as possible without box stacking.

- Q: What's the metal hose for fire fighting?

- Fire hose is an important component of modern industrial equipment connecting pipelines. The metal hose is used as wire, cable, automatic instrument signal wire, cable protection tube and civil shower hose, specifications from 3mm to 150mm. Small caliber metal hose (inner diameter 3mm-25mm) is mainly used for precise optical ruler sensing line protection and industrial sensor line protection.

- Q: Hose connector JB1885-77 what is the standard?

- The reason of high pressure hose joint leakage are the following: "a" ring aging or deformation caused by leakage; the "C" ring assembly is not in place, the two plane connection or "C" uneven pressure ring is cut caused by leakage; "a" ring without compaction, the elastic deformation caused by leakage; the "C" ring spigot groove deep caused leakage. In this regard, the need to re select the same diameter and thick section "C" ring, can also be provided with a sealing plane rabbet groove of cutting or grinding, in order to reduce the rabbet groove depth, the "C" ring has enough elastic deformation (compression should be between 0.35-0.65mm).

- Q: Acid burette and how to distinguish the basic buret

- The following is a rubber tube acid basic titration burette is below the piston

- Q: Can high speed air flow through a rubber tube and produce static electricity?

- To solve this problem, I suggest you do not focus on the voltage level, but focus on how to eliminate static electricity. For example, choose a low resistivity rubber material to ground and control the airflow humidity (if possible).If you really need to accurately grasp the size of the voltage caused by static electricity, and there is no reference to the literature, you may as well begin to study the experiment.

- Q: Is the rubber pipe joint installed in the middle of the pipe and pump for shock absorption?

- A pump is a machine that transports liquids or pumps liquids. It will be the prime mover of the mechanical energy or other external energy transfer to the liquid, the liquid energy increase, mainly used to transport liquids including water, oil, alkali liquid, emulsion, suspension emulsion and liquid metal, but also transport liquid, gas mixtures and liquids containing suspended solids. Pump performance of technical parameters are flow, suction, lift, shaft power, water power, efficiency, etc.; according to the different principles of work can be divided into volume pumps, vane pumps and other types. Displacement pump is to use its studio volume changes to transfer energy; vane pump is to use the rotating blade and water interaction to transfer energy, there are centrifugal pumps, axial flow pumps and mixed flow pumps and other types.

- Q: How to make sure the rubber hose will not be worn off?

- The ink jet machine can mark the laser marking machine on the pipe, and then mark the joint on the joint

Send your message to us

High Pressure Flexiable Rubber Fuel Hose

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords