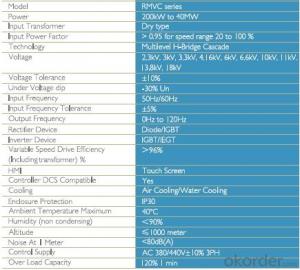

High Medium Voltage Drive 6KV 3000KW VFD

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Energy-saving Solutions for Enterprise

1、Program Overview

◆Saving energy achieves 10% -70%

◆The enterprises do not need to pay for expense of equipment manufacture and installation.

◆Enterprises only need to pay the saving electricity expense to our company according to the actual quantity of energy saving after the equipments put into operation.

◆According thousands of the projects’ implementation experiences, such projects recover the investments in three or four years. (Equipment service life is 15 years)。

◆Our company will no longer charge the saving electricity expense after recovering the investment.

The significance of the program:

1)、Concentrate on solving problems of energy conservation, make enterprises’ energy-saving work reach new level and take their social responsibility。

2)、Avoid the enterprises reactive power fine of low power factor caused by electric energy using (according to Ministry of Electric Power and Water Resources, State Price Control Bureau establish the " measures of power factor adjustment expense ").

3)、Avoid the high-energy consumption enterprises are implemented differential prices because of the changes of national power regulation.

4)、For the standard-conforming large-scale (saved energy equal 10 thousand tons standard coal or more) energy-saving technological transformation projects, China will reward the enterprises for energy saving which based on the "Financial Incentives Interim Measure for Energy-saving Technological Transformations" established by Ministry of Finance, the National Development and Reform Commission.( Amount of 200 yuan / ton of standard coal).

5)、Equipments recovery period is generally 3-4 years, each period payment equal to the amount of current energy-saving benefits, and equipments service life are 15 years, so enterprises will gain huge energy-saving benefits.

2、Implementation Process

Energy Audit

Energy Saving Program Design

Construction Design

Equipments Manufacture

Construction and installation

Maintenance and Repair

Energy Monitoring and Efficiency Insurance

Recovery of Program Investment

3、Program Features

High energy-saving efficiency

The project saving rate is generally 10% -30%, highest is up to 70%.

Clients Zero Investment

All works of design, audit, manufacturing, construction, monitoring are handled by RXPE, clients does not require investment.

Energy-saving Guarantee

RXPE promises the amount of energy saving, ensuring that clients’ cost reduction immediately.

Short Investment Recovery Period

The investment recovery period is short, average period is 3-4 years.

Low Risk

Customers do not input large sums of money also can enjoy professional energy-saving products, technologies and services, and the investment risk is very low.

Improvement of Cash Flow

Customers with the support of RXPE approve energy-saving program to improve cash flow, invest the limited funds into other priority investment areas.

Enhance competitiveness through implementing energy conservation, improving energy-saving efficiency, reducing energy costs and enhancing the quality of environment, establish green corporate image and enhance market competiveness.

- Q: Inverter alarm a043, how is it

- Check processing: Check if the cable is disconnected. Check the tachometer to shield the ground. The shield is not only on the motor side, but also on the inverter side The cable of the pulse encoder should not be disconnected. The pulse encoder cable can not be laid together with the power loop cable. Use only the recommended pulse encoder.

- Q: What are the types of power adapter used in notebooks?

- Notebook function is limited, such as power requirements of only 50-70 watts (W). In recent years, power requirements have risen above 100 W, but the expectations for weight and size have not improved accordingly. In addition, the need to meet the low standby power performance in the specification, external power (EPS) efficiency requirements and IEC1000-3-2 harmonic power requirements above 75 W make this challenge more difficult to deal with. This article explores new trends that enable power supply manufacturers to address these challenges and provide alternative solutions to choose from.

- Q: Can the inverter stop intermittently during operation? If so, how to connect and set up

- One of these terminals is a common terminal, which leads from the common terminal and is connected to the corresponding terminal via the relay contact

- Q: I have a 5.5 kilowatts of 4-pole motor, want to pass through the inverter, slow down to 130 per minute use, eliminating the need for speed,

- Power will drop, down to the original one-tenth

- Q: My laptop can not use the power adapter, and can only use the battery, how is it ah,

- I have encountered the same problem, plug in the adapter, or use the battery power, the battery alarm, not the battery charge, the power adapter can not be used. But the power can charge the battery. If the power adapter alone, one will automatically shut down. Measure the adapter voltage normally. And then to get the computer city maintenance department, gymnastics, it is a simple question, the original power line in the circuit board on the solder joints are loose, that is, Weld, resulting in insufficient current, no wonder, off the machine can charge, boot can not charge, It shuts down. Spent 100 yuan. Business really black. I saw the repair. On the welding a few times OK. No wonder, once I suddenly shot about, the adapter can be used. Later, how to shoot not work. However, although spent 100, but my computer's heat silicone grease for the whole, the computer CPU temperature is not so high before. The beginning of the maintenance staff said that the power management chip may be broken, if the bad to more than 100, then, no bad, just contact the problem, welding also received me 100, really depressed. In fact, you can say good, if the contact problem, certainly below 100.

- Q: Why the number of motor poles increased, the inverter capacity will increase

- The number of poles of the motor is not directly related to the rated current, but the number of poles is larger and the power factor is lower and the rated current will be higher.

- Q: Laptop power adapter how to detect?

- After opening to see what is burned, Estimated to be insurance and the like

- Q: The Schneider inverter reports the nlp command

- 1, the inverter control circuit with an external 24V power supply, the main circuit did not power 2, PO and PA between the short film can not cause this failure.

- Q: How to make the motor speed (control speed), can not use frequency

- If you use AC asynchronous motor speed control in three ways: 1 / variable speed control. By changing the motor stator pole pairs to speed, not the linear speed for the sub-file speed, the motor structure and electrical control more complex. 2 / electromagnetic speed control. Driven by the magnet magnet, the electromagnetic coil through the variable size of the DC to speed, for the linear speed, but a waste of energy 3 / frequency control. Through the inverter speed, stepless speed regulation, speed control effect is good, but one-time investment. If the DC motor speed is to change the armature or the excitation coil voltage to achieve speed. Application in the relatively high demand, a one-time investment is relatively large

- Q: Quartet of the TA, TC terminals have positive and negative?

- This can not be said to be positive and negative, should be called the public, TA, is the common.

Send your message to us

High Medium Voltage Drive 6KV 3000KW VFD

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords