Coir Geotextile Machine Compatible High Density Polypropylene Geogrid for Highway, Railway, and Municipal Road Applications

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Description

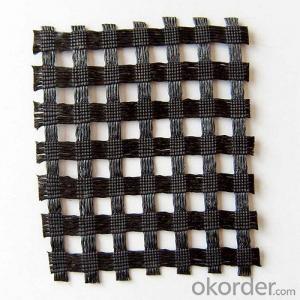

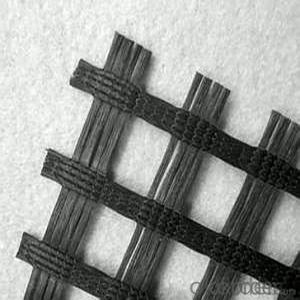

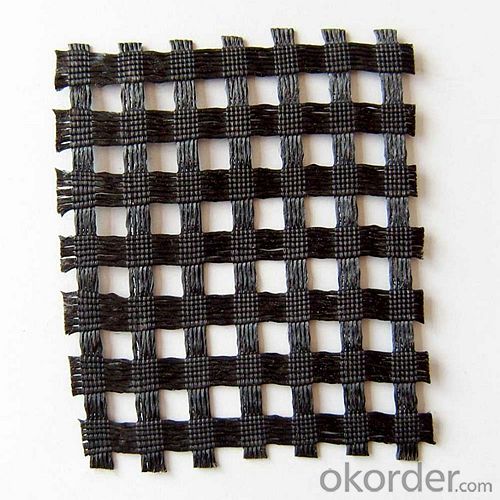

Geogrids form a distinct category of geosynthetics designed for reinforcement. These products are characterized by a relatively high tensile strength and a uniformly distributed array of large apertures (openings between the longitudinal and transverse elements). The apertures allow soil particles on either side of the installed sheet to come into direct contact, thereby increasing the interaction between the geogrid, aggregate and some soils. Also, the apertures ensure vertical drainage of a reinforced free-draining aggregate/soil.

Type:

Geogrids

Place of Origin:

Shandong, China (Mainland)

Brand Name:

OEM or Road

Model Number:

EGA50-50, EGA80-80, EGA100-100

Material:

Fiberglass

Coating:

asphalt

The geogrid elements vary in polymer type and cross-sectional dimensions. They can sometimes change shape and dimensions within their length. Geogrids are either integrally manufactured (punched and drawn sheets; or extruded), ultrasonically or adhesive bonded strips, or joined in a knitting or weaving process and then coated. Polymer types include polyethylene, polypropylene or high tenacity polyester that has been coated.

Although geogrids are used primarily for reinforcement, some products are designed for asphalt overlay and waterproofing or for separation and stabilization. Geogrids also are used as gabions and sheet anchors, inserted between geotextiles and geomembranes, or used to construct mattresses for fills or embankments over soft soils.

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Fish tank white filter cotton toxic, is not geotextile, or non-woven Yeah

- Geotextile do fish tank filter, fish will die

- Q: How do geotextiles help with separation of different soil layers?

- Geotextiles help with the separation of different soil layers by acting as a barrier or filter between them. They prevent the mixing of different soil types, preventing the migration of fines or small particles from one layer to another. This separation ensures the integrity and stability of each soil layer, allowing for better drainage and preventing the loss of structural properties.

- Q: How do geotextiles affect soil nutrient availability?

- Geotextiles can have both positive and negative effects on soil nutrient availability. On one hand, geotextiles can help retain nutrients in the soil by preventing their leaching and runoff, thus promoting their availability for plant uptake. On the other hand, if geotextiles are impermeable to water and air, they can hinder nutrient exchange processes and microbial activity, ultimately reducing nutrient availability in the soil. Therefore, the impact of geotextiles on soil nutrient availability depends on their design and application.

- Q: What are the factors affecting the performance of geotextiles?

- There are several factors that can affect the performance of geotextiles, including the type of material used, the manufacturing process, the installation method, the environmental conditions, and the design considerations. The strength, durability, and permeability of the geotextile, as well as its ability to withstand chemical and biological degradation, play a significant role in its performance. Additionally, factors such as soil characteristics, loading conditions, and the presence of water or chemicals can also impact the performance of geotextiles. Proper selection, installation, and maintenance are crucial in optimizing the performance and longevity of geotextiles.

- Q: How do geotextiles contribute to pavement design?

- Geotextiles contribute to pavement design by providing reinforcement, separation, filtration, and drainage functions. These synthetic materials enhance the strength and stability of the pavement by distributing loads, preventing the mixing of different layers, filtering out fine particles, and improving water drainage. Geotextiles help in reducing pavement failures, extending its lifespan, and improving overall performance and durability.

- Q: How do geotextiles affect air quality?

- Geotextiles do not directly impact air quality as they are primarily used for soil reinforcement, filtration, and drainage purposes in construction and landscaping projects. However, their use can indirectly contribute to better air quality by reducing soil erosion, preventing the release of dust particles into the air, and improving overall environmental sustainability.

- Q: Geotextile now how much money? what is the price?

- Geotextile, also known as geotextile, it is made of synthetic fiber through acupuncture or woven from the permeability of geosynthetics. Geotextile is a new material geosynthetics which one, the finished product for the cloth, the general width of 4-6 meters, the length of 50-100 meters. Geotextile is divided into a spinning geotextile and non-woven filament geotextile. Geotextile price in addition to weight (80-1500g / ㎡) to count, the quality standard is also a requirement, divided into non-standard, whitening A, Sinochem, the general national standard, Paul GB, Dahua GB and so on. Ton price is generally between 4000-8000 yuan / ton geotextile material manufacturers to answer

- Q: What are the key considerations for geotextile installation in seismic retrofitting projects?

- The key considerations for geotextile installation in seismic retrofitting projects include selecting the appropriate type and grade of geotextile based on site conditions, ensuring proper placement and anchoring of the geotextile to provide effective soil stabilization, assessing the potential for liquefaction and designing appropriate measures to mitigate it, considering dynamic forces and ground motion during installation, and conducting regular inspections and monitoring to ensure the geotextile's performance and effectiveness in withstanding seismic events.

- Q: Filament spunbond nonwoven geotextile performance requirements for what is the basic item

- Filament spunbond acupuncture non-woven geotextile is the implementation of the national standard GB / T-2008 standard. GB / T-2008 standard for filament spunbond acupuncture non-woven geotextile performance requirements of the basic items include: product vertical and horizontal nominal fracture strength (KN / m), vertical and horizontal nominal elongation at break (%) (KN), vertical and horizontal tearing strength (KN), mass per unit area deviation (%), width deviation (%), thickness (mm), vertical permeability coefficient (cm / s), equivalent pore size (O90 (95) / mm). Only the above indicators meet the corresponding GB / T-2008 standard requirements, be considered qualified filament spunbonded non-woven geotextile.

- Q: Can geotextiles be used in reservoir lining projects?

- Yes, geotextiles can be used in reservoir lining projects. Geotextiles are commonly employed to improve the stability and performance of reservoir linings by providing reinforcement, filtration, and separation functions. They can effectively prevent soil erosion, control seepage, and enhance the overall integrity and longevity of the reservoir lining system.

Send your message to us

Coir Geotextile Machine Compatible High Density Polypropylene Geogrid for Highway, Railway, and Municipal Road Applications

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords