High Alumina Bricks for Industrial Furnace - High Alumina Refractory Bricks

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 1500 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Description for High Alumina Refractory Bricks for Industrial Furnace

CMAX high alumina bricks are classified according to alumina content ranging from 48% to 90%.

CMAX high alumina bricks are commonly used in blast furnace, hot blast furnace, the roof of electric furnace, teeming ladle, rotary kiln, regenerator, etc.

Brief features for high alumina bricks

Low thermal conductivity

Excellent acid and base slagging resistance

High refractoriness

Excellent thermal shock resistance

Excellent mechanical strength

Good spalling resistance and wear resistance.

Good corrosion resistance.

High-temperature creep rate is quite low.

Good volume stability at high temperature.

Low bulk density, low thermal conductivity, good thermal insulation performance.

Technical data for high alumina bricks

| ITEM | UAL48 | UAL55 | UAL65 | UAL75 | UAL80 |

| Refractoriness, ℃ | 1750 | 1770 | 1790 | 1790 | 1810 |

| Apparent Porosity,% | 22 | 22 | 23 | 23 | 20 |

| C.C.S. Mpa | 39 | 44 | 49 | 53 | 55 |

| Refractories Under Load (0.6)℃ | 1420 | 1470 | 1500 | 1520 | 1500 |

| Reheating Linear Change (%) 1550℃×2h | 0.1 ~-0.4 | 0.1 ~-0.4 | 0.1 ~-0.4 | 0.1 ~-0.4 | -0.5~+0.5 |

| Chemical Composition (%)Al2O3 | 48 | 55 | 65 | 75 | 80 |

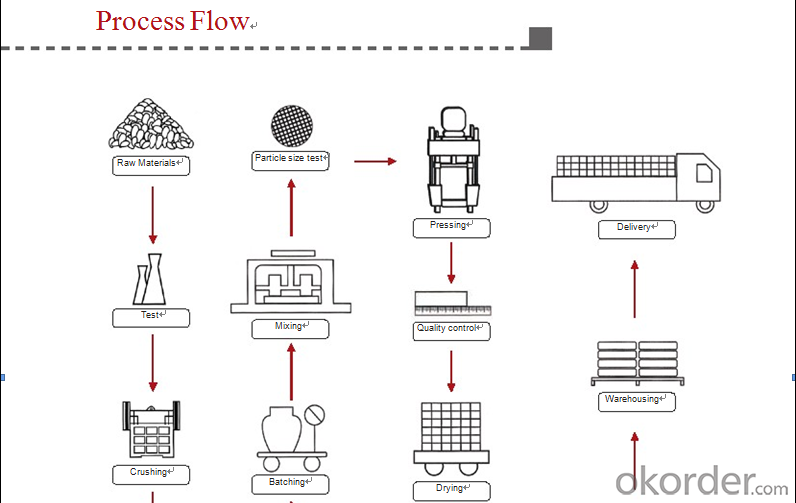

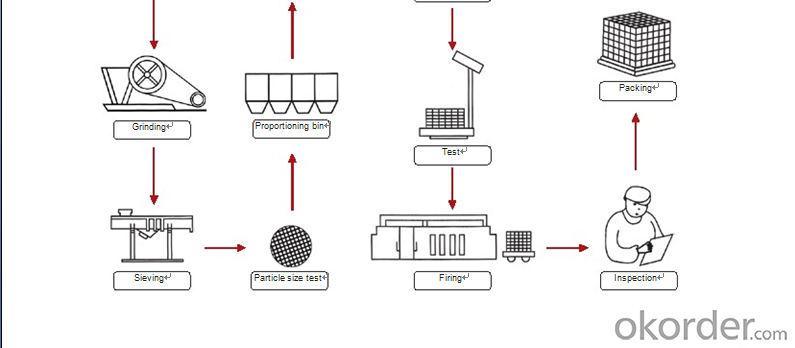

Images/photographs for high alumina bricks

FAQ

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Which payment terms can you accept?

A:T/T,L/C are available for us.

Q5:After an order is confirmed,when to deliver?

A:15-25days after deposit.

Q6:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q7:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q8:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q9:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q10:What is the service life of your bricks?

A:The service life of different bricks is unlike.It also depends on your using condition and method.

- Q: What are the high aluminum bricks made of?

- The amount of refractory mud accounts for about 6% of the brick weight

- Q: What is the standard classification of high alumina bricks and high alumina bricks?

- Refractory brick is non-metallic materials can be classified according to a kind of inorganic material, high aluminum brick, clay brick, magnesia brick, corundum brick, mullite bricks, silicon carbide materials such as brick, high alumina brick is used as a relatively wide range of products in accordance with the refractory brick high alumina refractory materials by high aluminum brick is generally divided into Al2O3 content three: I - II - >75% Al2O3 content; the content of Al2O3 is 60 ~ 75%; III - Al2O3 content from 48 to 60%.

- Q: The difference between aluminium refractory and magnesia refractory

- Therefore, the difference between the two is a neutral, one is alkaline, the original product is different naturally.

- Q: What is the content of free silica in the refractory bricks of high alumina bricks?

- Refractory powders are not rich in free silica in varying degrees

- Q: How much is one ton / ton of high alumina refractory brick?

- The price of high alumina refractory bricks is not equal, according to the quality index of GB2988-2012

- Q: What are the specifications for bricks?

- Ordinary brick size of 240 mm * 115 mm * 53 mm, according to compressive strength (Newton / square millimeter, N / mm2) size is divided into MU30, MU25, MU20, MU15, MU10, MU7.5, these intensity levels. Clay brick materials, cheap, durable, and fire prevention, heat insulation, sound insulation, moisture absorption and other advantages, is widely used in civil engineering. Waste brick can also be used as aggregate of concrete. In order to improve the shortcomings of ordinary clay bricks, such as small, self important and waste of soil, they are developing in the direction of light weight, high strength, hollow and big blocks.

- Q: Is glass wool inorganic thermal insulation material?

- Yes, glass wool belongs to one kind of glass fiber. It is a kind of man-made inorganic fiber. Therefore, in the field of thermal insulation materials classified as inorganic insulation materials.

- Q: Does the chimney have high acid resistance?

- The acid resistant bricks used for chimney are usually made of custom-made trapezoidal acid proof bricks, and the physical and chemical indexes of acid resistant bricks need to be confirmed according to the chimney's actual emission. At this point, you can consult our kerei refractories.

- Q: How does the physicochemical index change when the high alumina brick is used at high temperature?

- When the high alumina brick is used at high temperature, the physical and chemical indexes and other constants will not change if the temperature is in the physical and chemical indexes and the softening temperature of the load.

- Q: What should be used as binder for making high alumina bricks?

- In addition, high alumina micro powder can be used as binding agent, or high alumina micro powder and clay powder are prepared according to a certain proportion, and synthetic mullite is used as bonding agent. With these binders, high alumina bricks without two expansion can be prepared.

Send your message to us

High Alumina Bricks for Industrial Furnace - High Alumina Refractory Bricks

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 1500 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords