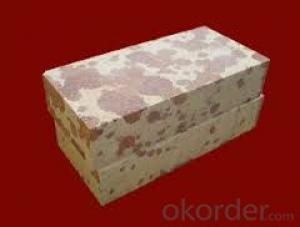

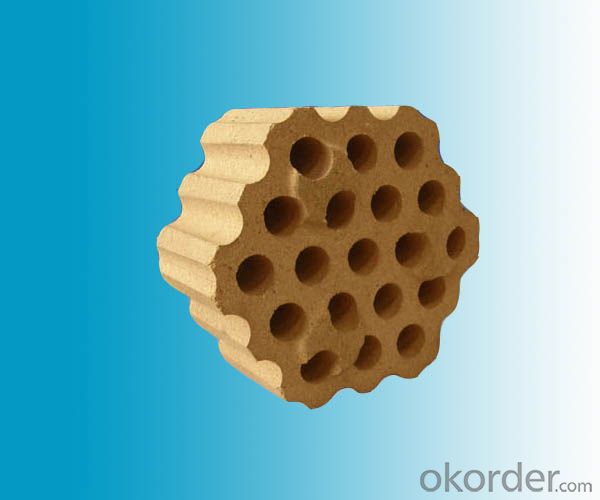

High Alumina Refractory Brick for Cement Kiln Copper Aluminum Melting Induction Furnace

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Alumina Refractory Brick for Cement Kiln Copper Aluminum Melting Induction Furnace

Company profile:CNBM internation MATERIAL CO., LTD is the specialized manufacturer and supplier of refractory in China, Our products mainly include refractory bricks, refractory castable, refractory precast shape, insulating brick etc. For refractory castable and precast shape they are very popular in the Europe, North American area.

Index | LZ-48 | LZ-55 | LZ-65 | LZ-75 | LZ-80 | LZ-85 | |

Al2O3 % | ≥48 | ≥55 | ≥65 | ≥75 | ≥80 | ≥85 | |

Fe2O3 % | ≤2.5 | ≤2.5 | ≤2.0 | ≤2.0 | ≤2.0 | ≤1.8 | |

Refractoriness °C | 1760 | 1760 | 1770 | 1770 | 1790 | 1790 | |

Apparent porosity % | ≤23 | ≤23 | ≤23 | ≤23 | ≤22 | ≤22 | |

Refractoriness under load 0.2MPa°C | 1420 | 1470 | 1500 | 1520 | 1530 | 1550 | |

Cold crushing strength MPa | 45 | 45 | 50 | 60 | 65 | 70 | |

Permanent linear chang % | 1500°C×2h | +0.1~0.4 | +0.1~-0.4 | +0.1~-0.4 | +0.1~-0.4 | +0.1~-0.4 | |

1450°C×2h | +0.1~-0.4 | ||||||

Our services:

1.Adhering to the business philosophy "Mutual Trust, Mutual Benefit, Mutual Profit, Faith Oriented".

2.According to your requirements to produce your order and OEM/ODM service is available.

3.Products are inspected through SGS and BV etc and accord with the international standard.

4.Your inquiry related to our products or prices will be replied in a timely manner.

Application:

Refracory brick plant can be in direct contact with the flame,this insulating brick can be used as linings or as thermal preservation layers in various industrial furnaces and kilns in metallurgical industry, ceramic industry, chemical industry, machinery industry.

such as blast furnace, hot blast stoves ,electric arc furnace, cement kiln,melting furnace, ignition furnace, flue, refining equipment, heating equipment and piping, regeneration device, gas furnace, soaking furnace, annealing furnace, heat reaction chamber and other thermal industrial equipment.

FAQ

1. Do you provide samples?

Yes, samples are free. Guarantee samples quality same as mass production quality.

2. What's the MOQ of trial order?

No limit,We can offer the best suggestions and solutions according to your condition.

3. Can we visit your company?

Of course,welcome at any time,seeing is believing.

4. Do you accept OEM?

Yes, we can do OEM.

5. What are the payment terms?

Usually T/T, D/A, D/P, L/C, Western Union ,others could be discussed .

6. How long is delivery time?

The delivery time will be determined according to the quantity of the order.

7. How are your products’ quality?

More than 20 years of production experience. The products will be strictly inspected before shipment, so the quality could be guaranteed.

8. How to slove the quality problems?

If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

9. What is the service life of your bricks?

The service life of different bricks is unlike.It also depends on your using condition and method.

10. How about your company's certification?

ISO9001 and Test Report,also we could apply other necessary certification.

11. How about your price?

Quality will be guaranteed. Competitive prices based on same quality.

- Q: What are the main components of high alumina bricks?

- Sweat is like water mineral alumina bauxite, aluminum ore, magnesite, waves of gibbsite. Anhydrous alumina raw material, such as corundum, alumina, fused corundum. High alumina brick Zhengzhou gold company specializing in the production of various specifications, you can directly ask their technical staff.

- Q: What are the reasons for the decline in the performance of high alumina bricks when we use high alumina refractory bricks?

- The brick Pei boring and time. 6, Pei brick kiln installed between the brick and the brick Pei order, Pei and kiln top, kiln wall gap etc.. 7, high alumina brick kiln plan, and the lack of edges and corners of the scene should be avoided.

- Q: What is the price of the first grade high alumina brick?

- Many factories in Xinmi have high alumina bricks, but they must choose a regular factory. Kuwait refractory level high aluminum brick price at around 1600, the quality of double stable supply

- Q: The difference between aluminium refractory and magnesia refractory

- Therefore, the difference between the two is a neutral, one is alkaline, the original product is different naturally.

- Q: How to make refractory bricks and boiler wall adhesion more firm?

- Suggest that you use fire brick to increase the length of brick or pull the amount of turn, and use high temperature mortar masonry

- Q: Aluminum content 38, silicon content 55 What refractory bricks?

- Semisilica brick: the content of Al2O3 is 15% ~ 30% of aluminium silicate refractory products. Manufacturing products are semi silica quartz containing impurities or native clay kaolin, refractory clay or kaolin beneficiation tailings and the pyrophyllite

- Q: What kinds of minerals are there in the five major categories of ore crystal chemistry?

- Halide. A few species, about 120 species, accounting for only 0.1% of the earth's crust. Most of them formed in the surface conditions, forming a salt mineral, containing less pigment ions, light color, low hardness, generally less than 3.5. Common mineral halite (NaCl), potassium (KCl), fluorite (CaF2) etc..

- Q: How high can aluminum bricks expand at 80O degrees of heat?

- When an object is heated, the particle moves faster and thus occupies additional space. This phenomenon is called dilation.

- Q: What is the high temperature limit of refractory bricks and refractory soil?

- According to the preparation process can be divided into bricks, brick, electric melting brick (Rong Zhuzhuan), the refractory insulating bricks; according to the shape and size can be divided into standard brick, ordinary brick, specific rotation. It can be used as high temperature building materials and structural materials for construction kilns and various thermal equipments, and can undergo various physical, chemical and mechanical changes at high temperature.

- Q: The difference between clay bricks and clay bricks

- According to the hole rate: solid brick (no hole or hole rate less than 25% bricks), porous brick (hole rate is equal to or greater than 25%), the size of the hole is small and the number of bricks, usually used in load-bearing parts, higher strength level. Hollow brick (hole rate equal to or greater than 40%, large pore size and small amount of brick, commonly used in non load parts, low strength grade).Solid bricks and porous bricks are mostly used for load-bearing structural walls. Hollow bricks are mostly used in non load bearing structures.

Send your message to us

High Alumina Refractory Brick for Cement Kiln Copper Aluminum Melting Induction Furnace

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords