High Alumina Brick for Mining Industry - 92% Alumina Content

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 11 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Wear resistance ceramic brick

Ceramic lining brick

High alumina brick

Ceramic heat brick

Highly abrasion and impact resistan

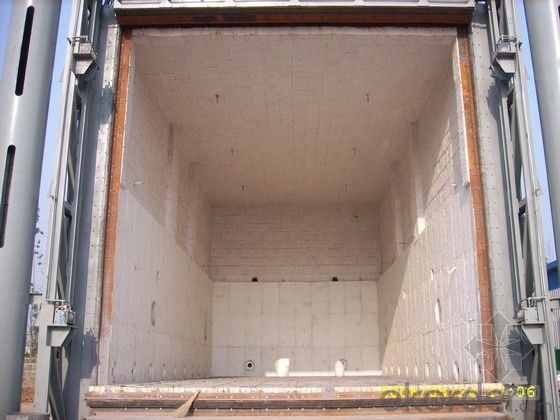

92% High Alumina Brick for Mining Industry

Wear Resistance Shaped Brick

Ceramic lining brick

High alumina brick

Ceramic heat brick

Highly abrasion and impact resistance

Quick delivery

wear resistance ceramic linning brick

92% High Alumina Brick for Mining Industry

Alumina ceramic liner

Features:

1. Highly abrasion and impact resistance

2. Smooth iiner wall

3. Lowest Cost

4. Excellent corrosion resistance

92% High Alumina Brick for Mining Industry

We can offer the conventional specifications of them, and we also specilize in designing and manufacturing them upon customers' drawings or dimension.

92% High Alumina Brick for Mining Industry

- Q: Is there a big difference between two high alumina brick and one high alumina brick?

- According to my experience, two kinds of high alumina bricks from the index, there is a big difference between the content of AL2O3, a high aluminum brick in 75%, two grade high alumina bricks in 65%, so the content is not the same, also decided that the use of temperature difference, the difference is very big.

- Q: How much is one ton of high alumina refractory brick?

- Three high aluminum refractory brick Zhengzhou Kuwait is generally around 800. 32 years of experience, good.

- Q: What are the requirements for Rubble backfill height?

- Backfill should be filled with large stones, big face, small face upward, the decoration is stable, and then use small stones leveling, the gap between the stones can be swept into the slag, gravel, so that the gap filled.

- Q: Density of high alumina bricks

- The density of high alumina bricks is determined according to the price. The average density is between 2.3-2.5g/cm3. The higher the density, the higher the price, the higher the aluminum bricks are in the industry. More than 2.4 are required.

- Q: What is the content of free silica in the refractory bricks of high alumina bricks?

- Refractory powders are not rich in free silica in varying degrees

- Q: What are ordinary bricks, refractory bricks, hollow bricks?

- Light yellow or brownish. The utility model is mainly used for laying smelting furnaces, and can withstand high temperature between 1580 DEG C and 1770 DEG C. Also called brick. Refractory material of a certain shape and size. According to the preparation process can be divided into bricks, brick, electric melting brick (Rong Zhuzhuan), the refractory insulating bricks; according to the shape and size can be divided into standard brick, brick, brick and other specific type. It can be used as high temperature building materials and structural materials for construction kilns and various thermal equipments, and can undergo various physical, chemical and mechanical changes at high temperature. For example, refractory clay brick, high alumina brick, brick, brick etc..

- Q: Does the chimney have high acid resistance?

- If it is an ordinary high alumina brick, it does not meet the requirements of acid resistance, and only the chimney lined with acid resistant bricks.

- Q: What is the difference between fireclay bricks and high alumina refractory bricks?

- High alumina brick is one of refractory materials. The main component of this kind of refractory brick is AL2O3.

- Q: What should be used as binder for making high alumina bricks?

- Bond for making high alumina brick: soft clay has good plasticity, so the high alumina brick is usually made of soft clay as bond. However, the free Al2O3 free SiO2 and bauxite clinker clay in under 1200 degrees occurred two times of Mullization reaction, generate large volume expansion, silicon porosity, strength reduction. Therefore, the amount of clay powder in the ingredient should be no more than 5%.

- Q: High alumina brick 80 with which high aluminum cement?

- Which kind should be chosen should be determined according to the conditions of use, life expectancy and cost control. By the way, the quality of masonry is also very influential.

Send your message to us

High Alumina Brick for Mining Industry - 92% Alumina Content

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 11 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords