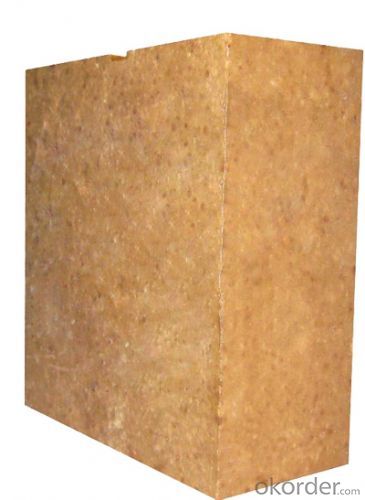

High Alumina Brick - 75%-80% Al2O3 for Steel Ladle Linings

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 800000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Shanxi, China (Mainland) | Shape: | Brick | Material: | Alumina Block |

| SiO2 Content (%): | 0 | Al2O3 Content (%): | 55-80 | MgO Content (%): | 0 |

| CaO Content (%): | 0 | Refractoriness (Degree): | 1770°< Refractoriness< 2000° | CrO Content (%): | 0 |

| SiC Content (%): | 0 | Model Number: | CL-55 CL65 CL75 CL80 | Brand Name: | CNBM |

| AL2O3: | 55-80% |

Packaging & Delivery

| Packaging Details: | ABOUT 1MT WOODEN PALLET |

| Delivery Detail: | WITHIN 45DAYS |

Specifications

High Alumina Bricks for Steel Ladle Linings

AL2O3:55-80%

ISO9001-2008

HIGH ALUMINA BRICKS FOR STEEL LADLE LININGS | ||||||

Goods Brand | CL-55 | CL-65 | CL-75 | CL-80 | PZCL-78 | |

Al2O3(%) min | 55 | 65 | 75 | 80 | 78 | |

Refractriness under load 0.2 Mpa ( °C) min | 1470 | 1490 | 1510 | 1530 | 1550 | |

Apparent porosity (%) max | 22 | 28 | 28 | 24 | 21 | |

Cold Crushing strength (MPa)min | 45 | 35 | 40 | 50 | 70 | |

Shrinkage after reheating (%) max | 1450°Cx2h | 0.1~0.5 | *** | *** | *** | *** |

1500°Cx2h | *** | 0.1~0.5 | 0.1~0.5 | *** | *** | |

1550°Cx2h | *** | *** | *** | 0.1~0.5 | 0.4~0.3 | |

Our Service:

1. Your inquiry related to our products or prices will be replied in 24hours.

2. Manufacturer with large capacity, ensure the fast production cycle after confirmed the order.

3. Our professional technicians will answer your entire enquiry in patient.

4. To meet the refractory solutions, we can serve as your instructions.

5. Protection of sales area and private information for our entire customer.

If you’ve kind enquiries, please don’t hesitate to let us know. ^_^

- Q: In 2016, a few of the traditional refractory materials will be able to survive

- The other is in large enterprises and individual has the unique advantage of the small enterprises, with independent technology system, production equipment advanced, there are certain funds set up to deal with risk, timely reform, such enterprises compared to a few years ago the productivity and sales or have declined, but overall is still in the stage of production increased steadily.

- Q: What is the price of the latest thermal insulation material?

- There are many kinds of insulation materials, and the price will fluctuate with the market. Small quantities of inquiry or procurement, then go directly to the local thermal insulation market, a wide variety of prices are basically the market price.

- Q: Can high alumina brick resist carburizing?

- The resistance to carburization is not directly related to the bulk density of bricks

- Q: Corundum, high alumina and fireclay refractory difference is what

- Corundum is unknown. The high alumina brick has higher aluminum content than the clay brick, and the temperature resistance is higher than 300 degrees. It is more durable and durable than the clay brick. The production process of high alumina brick is better than that of clay brick. For example, the weight of good clay brick is 3.7kg, and that of high alumina is 4.2kg. Good density. But the price of high aluminum is too high: ordinary clay brick (standard brick example) in 1.1--2.5 yuan / block, high aluminum to 4.5 yuan / block, or even more expensive. The extra high aluminum has reached 5000 tons. Say straight white point is: under the same conditions, clay brick for a period of one year, then the high aluminum for more than three years.

- Q: What are the high temperature refractory mortars made of?

- Products used in metallurgy, building materials, machinery, chemical, power industry, industrial thermal furnace, for masonryBuilding clay brick, high alumina brick and corundum brick have the characteristics of full grey seam, good airtightness, high bonding strength, high temperature performance and suitable construction time

- Q: The difference between light high alumina brick and heavy aluminum brick

- Lightweight high alumina brick, also called high alumina insulation brick. Alumina content of 48% or more, mainly from mullite and glass phase or corundum composition of lightweight refractory. Volume density 0.4 - 1.35g/cm3. Porosity 66% - 73%, compressive strength 1 - 8MPa. Better thermal shock resistance. Usually, a high alumina clinker is added with a small amount of clay. After grinding, it is poured and shaped in the form of slurry by gas generation or foam method, and it is fired at 1300 - 1500 DEG C. Sometimes industrial alumina can be used instead of some bauxite clinker. Used for lining and insulation of masonry kilns, as well as for areas where there is no strong, high temperature molten material erosion and erosion. When contacting the flame directly, the surface contact temperature shall not be higher than 1350 degrees centigrade.

- Q: What kind of material is the general metal case?

- We usually discuss the electromagnetic radiation of computer enclosures, mainly RF radiation, followed by MF leakage.Switch signal of RF radiation from computer high-speed leakage, such as one of the energy radiation is CPU frequency, graphics, display output line, keyboard, is the source of the operating characteristics of the computer leaked out, is also the main part of computer security.For the absorption of radio frequency radiation, the best is the use of copper materials, the use of other metals can also, thickness enough on the line.The most vulgar description is that people can sit in the case is a good thing.

- Q: What causes breakage of refractory bricks?

- There are many factors that lead to the damage of refractory brick, can be divided into: the chemical loss (e.g. salt penetration, redox phenomenon), heat loss (burning, thermal shock), mechanical loss (kiln deformation, thrust, brick masonry quality etc.).

- Q: How can the refractory brick blast furnace be pulverized and pulverized enough not to be taken away by the wind?

- Top burning type hot blast stoveIt means that the burner is installed on the top of the hot blast furnace of the iron making equipment, and it does not need a special combustion chamber in the vault space. It is also called a non combustion chamber type hot blast stove.

- Q: What should be used as binder for making high alumina bricks?

- In addition, high alumina micro powder can be used as binding agent, or high alumina micro powder and clay powder are prepared according to a certain proportion, and synthetic mullite is used as bonding agent. With these binders, high alumina bricks without two expansion can be prepared.

Send your message to us

High Alumina Brick - 75%-80% Al2O3 for Steel Ladle Linings

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 800000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords