Corundum Brick - High Abrasion-Resistant Chrome Corundum Steel Tapping Spout Brick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

In order to catch the rapid increasing demand of grinding media and provide full series to customers,we have developed grinding media with 92% AI2O3,75% AI2O3 AND 65% AI2O3.The technical data of each series is listed as following table.

With overwhelming merits in higher density,more regular shape,easily classifying and assorting,superior grinding efficiencies and competitive price prior to natural cobble stones and conventional grinding media,our Alumina Grinding Media are excellent for grinding processing of ceramic bodies and glaze materials in tile industries and surface polishing of the ceramic bearing applicant.

Specifications

1. Low thermal conductivity

2. High strength and resistance to corrosion

3. Low heat capacity

4. Low content of impurities

5. High insulation

6. Excellent thermal shock resistance

7. Low density

Features

1.High density

2.Strong corrosion resistance

3.Good slag resistance

4.Low permannent liner change on reheating

Application

Corundum brick primarily used for the key parts of the industrial furnace of steel,metallurgica,electronics,petrochemical,chemical fertilizers,non-ferrous metals,refractorty material etc high temperature industrial kiln furnace,such as glass furnace,cement kiln, heaters molten steel ladle,metallurgical furnaces for nonferrous metals and furnaces for chemical engineering industries.

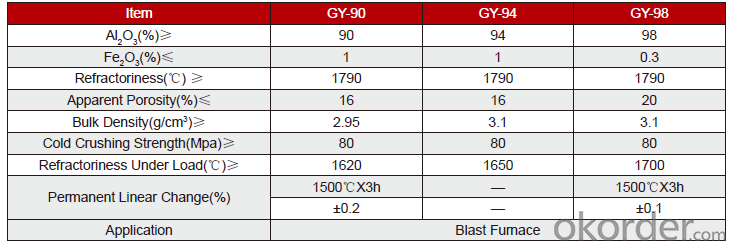

Physical properties and chemical composition

FAQs

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: How much is a refractory brick?

- There are many kinds of refractory bricks, you have to look at what is material, the material is not the same, the price is not the same, clay brick is the cheapest, probably hundreds of dollars a ton, and corundum brick a ton of several money, silicon carbide, silicon nitride, and more expensive. And this thing is generally on t sell, the price is by a single block after conversion.

- Q: What is the main component of corundum?

- The name of corundum originates from India and is the name of mineralogy. There are three main variants of corundum Al2O3, which are alpha -Al2O3, beta -Al2O3 and gamma -Al2O3 respectively. Corundum is second only to diamond.

- Q: What material is used in an iron smelting furnace?

- In fact, refractory refractory ah is special ceramic frequently used AZS brick, corundum brick, magnesia chrome brick, silicon carbide, silicon nitride bonded silicon carbide, nitrides, silicides, sulfide, boride, carbide and other non oxide refractory materials; calcium oxide, chromium oxide, alumina, Magnesium Oxide, beryllium and other refractory materials.

- Q: What is the price of concrete self insulation bricks?

- Insulation brick prices also have a great relationship with the material and workmanship, such as clay brick price is much lower than high alumina brick, mullite and corundum brick prices will be higher.

- Q: What is the blast furnace ceramic cup called by the refractory factory?

- The refractory bricks, which are suitable for blast furnace conditions, are vitrified by high temperature sintering. They are like a huge cup, so they are called ceramic cups. The name was taken by the French, and the technology was handed down from france!

- Q: How do corundum bricks bind?

- Each refractory brick is provided with corresponding refractory mud, and corundum bricks are bonded with corundum mud.

- Q: What kind of refractory material will be used in the glass kiln?

- The content of ZrO2 in the brick is about 66%, and the bulk density is 3.7g/cm3, which has better thermal stability and anti stripping property. The use of erosion serious investment outlet area and after the parapet wall in the powder melting furnace, observation hole brick and pathway of flame space and roof parapet wall brick, brick burner. But there are also AZS burner brick with mullite brick for brick kiln and transition two side clearance brick etc..

- Q: What is the difference between T3 refractory bricks and high alumina refractory bricks?

- The T3 in T3 refractory bricks refers to the model indicating that the refractory brick model is T-3, and that the corresponding T-3 model is 230*114*65 (mm)

- Q: What are the refractory materials?

- Many kinds of refractory materials, usually by refractoriness level is divided into ordinary refractory materials (1580 to 1770 DEG C), advanced refractories (1770 to 2000 DEG C) and special refractories (more than 2000 DEG C); according to the chemical characteristics into acid refractory material, refractory materials and basic refractory materials. In addition, there are refractories for special occasions.

- Q: What can zirconium sponge do for those industries?

- Zirconium metal, also known as sponge zirconium, silver gray metal, the appearance of steel, shiny; melting point 1852 points, sub points, boiling point 4377 density 6.49. Zirconium is easy to absorb hydrogen, nitrogen and oxygen; zirconium has a strong affinity for oxygen; at 1000 DEG C oxygen dissolved in zirconium can make its volume increase significantly. Zirconium is relatively stable in the air; powder zirconium is easy to burn; fine zirconium wires can be ignited by matches; at high temperatures they can be combined directly with dissolved oxygen, nitrogen and hydrogen.

Send your message to us

Corundum Brick - High Abrasion-Resistant Chrome Corundum Steel Tapping Spout Brick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords