Corundum Brick - High Compressive Strength Refractory

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

With overwhelming merits in higher density,more regular shape,easily classifying and assorting,superior grinding efficiencies and competitive price prior to natural cobble stones and conventional grinding media,our Alumina Grinding Media are excellent for grinding processing of ceramic bodies and glaze materials in tile industries and surface polishing of the ceramic bearing applicant.

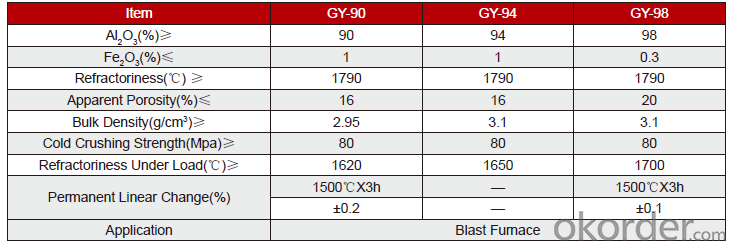

Specifications

1. Low thermal conductivity

2. High strength and resistance to corrosion

3. Low heat capacity

4. Low content of impurities

Features

1.High density

2.Strong corrosion resistance

3.Good slag resistance

4.Low permannent liner change on reheating

Application

Corundum brick primarily used for the key parts of the industrial furnace of steel,metallurgica,electronics,petrochemical,chemical fertilizers,non-ferrous metals,refractorty material etc high temperature industrial kiln furnace,such as glass furnace,cement kiln, heaters molten steel ladle,metallurgical furnaces for nonferrous metals and furnaces for chemical engineering industries.

Physical properties and chemical composition

FAQs

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: What is the main component of corundum?

- The name of corundum originates from India and is the name of mineralogy. There are three main variants of corundum Al2O3, which are alpha -Al2O3, beta -Al2O3 and gamma -Al2O3 respectively. Corundum is second only to diamond.

- Q: What are the advantages of refractories?

- Acid refractory material usually refers to refractories with SiO2 content greater than 93%. Its main characteristic is that it can resist acid slag corrosion at high temperature, but it is easy to react with alkaline slag.

- Q: What does refractory consist of?

- According to the shape of the product is shaped and unshaped refractory materials two categories, according to the chemical properties of acidic, neutral and alkaline refractory materials three categories, commonly used as refractory material of alkaline and neutral, such as magnesia, alkaline burned magnesia brick, magnesia chrome brick, magnesia calcium brick, high alumina brick, corundum neutral brick, clay brick, including: unshaped castable, ramming material, gunning material, coating material, dry vibration material etc..

- Q: What is the blast furnace ceramic cup called by the refractory factory?

- The refractory bricks, which are suitable for blast furnace conditions, are vitrified by high temperature sintering. They are like a huge cup, so they are called ceramic cups. The name was taken by the French, and the technology was handed down from france!

- Q: What equipment is used for producing diamond blanks? How much is the investment?

- Plus all the cables fifty thousand. Steel 10000 yuan. Corundum bricks; insulating bricks; clay bricks, these three require more than ten thousand. The electrode is about one hundred thousand. It's just an investment in an electric furnace. Together with the rear section processing and raw materials need hundreds of thousands of.

- Q: Expansion ratio of lightweight corundum refractory bricks

- Light corundum refractory brick, because of its production methods and the introduction of different additives, there are certain differences in the content of Al2O3, just burn add general light corundum refractory brick and foam and gasification method cannot be made, the content of Al2O3 is generally not more than 99%, with alumina hollow ball manufacturing transfer are corundum brick with high content of Al2O3.

- Q: What refractory materials are adopted in each part of the blast furnace?

- Bosh temperature reaches 1600~1650, high alumina brick, corundum brick or silicon carbide brick. The upper hearth tuyere zone near the temperature at 1700~2000 Deg. C, the use of sillimanite brick, corundum and silicon carbide refractory filler, Shi Mozhi. Bottom temperature at 1450~1500 Deg. C, the use of graphite bricks and microporous carbon brick, now also used corundum brick, Gang Yumo brick and synthetic mullite brick.

- Q: High temperature refractory material?

- Acid refractory with silicon oxide (SiO2) as the main ingredient, commonly used are silica brick and clay brick is siliceous. Products containing more than 93% SiO2, the use of raw materials with silica, silica and other waste brick. Acid slag erosion ability is strong, but vulnerable to the erosion of basic slag, its softening temperature is very high that is close to the refractory, the volume does not shrink after repeated burning, or even a slight swelling, but the thermal shock stability. Silica is mainly used for thermal equipment of coke oven, glass furnace, furnace and other acidic silica brick, according to the physicochemical indexes and SiO2 content can be divided into several levels, mainly brick for glass furnaces and used for coke oven two kinds of brick clay brick. With refractory clay or bauxite clinker as main raw material, containing 30% to 46% of alumina, refractory degrees 1580 to 1770 DEG C, weak acid refractory material, heat shock resistance, resistance to acid slag, wide application Pan, clay brick with refractory clay as main raw material is called ordinary clay brick, made with bauxite clinker as main raw material, the porosity in the clay brick below 17% is called low porosity clay brick. Two kinds of clay brick and according to the physicochemical indexes which were divided into several grades, the price difference between ordinary clay brick and low porosity clay brick greatly.

- Q: What kind of refractory material will be used in the glass kiln?

- High temperature & glass corrosion performance of the brick is slightly lower than that of chromium oxide, also by isostatic pressing forming method, its technical indicators ZrO2>65%, <2.0% porosity, volume density of about 4.25g/cm3, the temperature in E glass is higher than 1370 DEG C have erosion. Used in the E glass melting pool unit kiln glass temperature slightly lower at the end of the transition path, forming the bottom of the pool and forming path path flow tank and bushing support brick etc.. In addition, the dense zirconia brick is used as the backing brick of the dense chrome brick.

- Q: What problems should we pay attention to in the use of fused zirconia corundum brick (fused zirconia corundum brick) in glass furnace?

- Casting, casting mouth often appear shrinkage, brick porosity more, the density is lower, so in the brick wall of glass melting, the shrinkage in the kiln direction, if the nozzle outward, when the brick to erosion is very thin, can cause leakage of liquid glass accident. When the flame space is used in the upper part of the bath furnace, the service life is long, and the glass liquid problem can not happen, so the casting mouth is used outwards, and the service life is prolonged.

Send your message to us

Corundum Brick - High Compressive Strength Refractory

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords