Height 88mm the Thickness 18mm Surface and Length: according to the requirements of Channel Steel

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

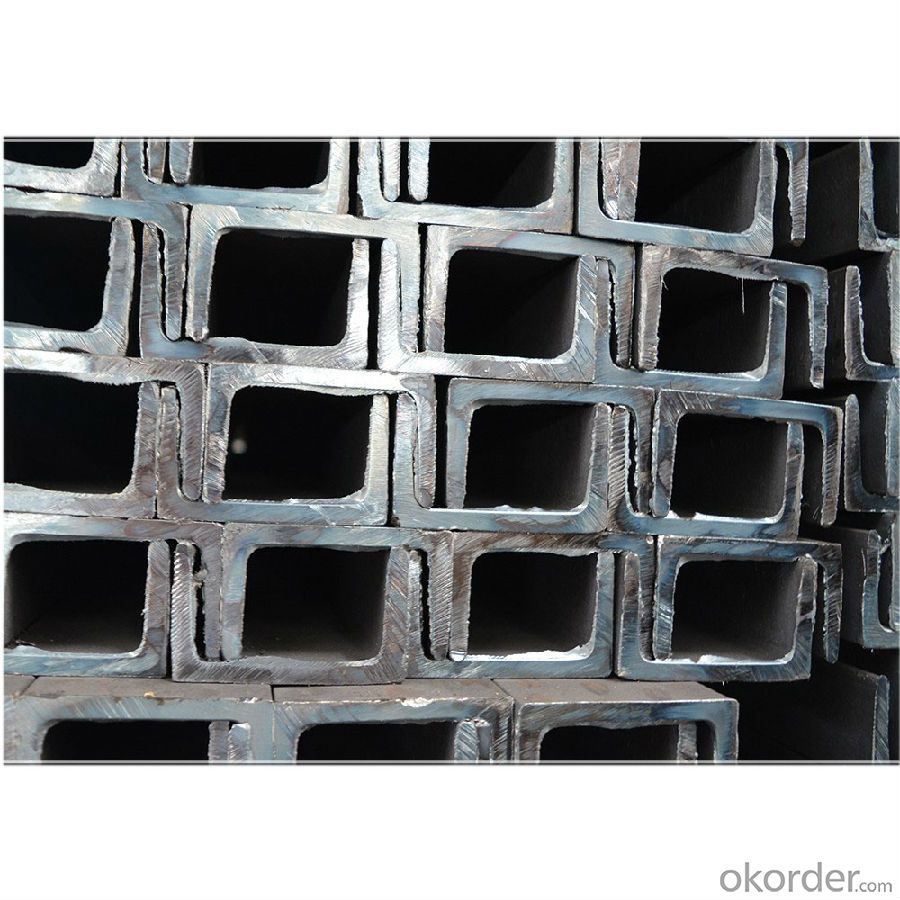

U Channel Steel the Length Thickness According to the Customer

1、the details information of our Channel Steel

1)the ordinary model

Height: | 90-400mm |

Thickness: | 9-14.5mm |

Surface: | according to the customers’ requirements |

Length: | As customers’ requirements |

Size: | 90*37*4.5mm--400*104*14.5 mm . |

Punch: | Can be punched as customer's drawing |

Material: | Q195/Q235/ Q215/Q345/SS400/S235JR, A36,SS400,SS540 ASTM A36 and so on |

2)the light model

Height: | 90-400mm |

Thickness: | 6.4-8.0mm |

Surface: | Painted or Galvanized;according to the customers’ requirements |

Length: | As customers’ requirements |

Size: | 50*32*4.4mm--400*115*8.0mm . |

Punch: | Can be punched as customer's drawing |

Material: | Q195/Q235/ Q215/Q345/SS400/S235JR, A36,SS400,SS540 ASTM A36 and so on |

2、the Product Advantage

1) We can design the channel steel according to customers’requirements

2) We can manufacture under complete quality control system---ISO9001&SGS

3) We can installed with instruction of experienced engineers

4) Easy to assemble and dismantle

5) Eco-friendly material: can be used for several times and can be recycled

6) Shorter construction period, longer using time

7) High strength and stiffness, high weight bearing.

3、why choose us ?Product Advantage

1)The channel steel quality is prime quality

2)Our price is competitive price with our competitor

3)We provide the professional service

4)Prompt delivery & Seaworthy packing

5)Mill Test Certificate

Company Information

which is one of the largest manufacturing bases of Steel Channel in northern China. We are a company that is specialized in producing Stainless Steel Channel、Prime Stainless Steel Channels and so on.

With years of development, our company won the trust and excellent reputation of customers for the quality of our products and sincere service, as well as foreign users of the community.

Please contact me if you are interested in our products and I will try my best to offer you the best goods and service.

- Q: Can steel channels be used in solar panel mounting structures?

- Yes, steel channels can be used in solar panel mounting structures. Steel channels provide a strong and durable framework that helps support and secure solar panels in place. Their versatility and ability to withstand various weather conditions make them a suitable choice for solar panel mounting systems.

- Q: What are the different methods of painting steel channels?

- Painting steel channels can be done using various methods, each with its own advantages and considerations. Let's explore some of these methods: 1. Brush painting: The traditional and most basic method involves using a paintbrush to directly apply paint onto the channel's surface. This technique is ideal for smaller projects or areas that require precise detailing. However, it can be time-consuming and may result in brush marks or uneven coverage. 2. Spray painting: A popular method, especially for larger projects or areas that require a smooth and even finish, is spray painting. This technique involves using a spray gun or aerosol can to create a fine mist of paint that is sprayed onto the surface. Spray painting allows for quick and efficient coverage, even in hard-to-reach areas. However, it requires proper ventilation and protective equipment to ensure safety. 3. Powder coating: For a highly durable and long-lasting finish, powder coating is an excellent choice. This method involves applying a dry powder paint that is then cured with heat to create a protective and smooth finish. Powder coating provides excellent resistance against corrosion, chemicals, and UV rays. It is commonly used in industrial applications and offers a wide range of color options. However, it requires specialized equipment and expertise, making it more suitable for professional applications. 4. Electrostatic painting: Another technique is electrostatic painting, which utilizes an electrostatic charge to attract paint particles onto the steel channel's surface. A spray gun is used to produce a charged paint mist, which is then attracted to the grounded channel. This method ensures even coverage and minimizes overspray. Electrostatic painting is commonly used when a high-quality finish and uniform coating thickness are required. 5. Dip painting: For objects with complex shapes or hard-to-reach areas, dip painting is a suitable method. This involves immersing the steel channel into a container filled with paint, allowing the paint to evenly coat the surface. Dip painting can achieve a uniform finish but requires careful control of the immersion process to prevent excess paint buildup or drips. Each method has its own advantages and considerations. The choice of painting method depends on factors such as the project size, desired finish, durability requirements, and available resources. It is crucial to consider the specific needs and constraints of the project before selecting the most suitable method for painting steel channels.

- Q: Are steel channels suitable for corrosive environments?

- Depending on the specific conditions and the type of steel used, steel channels may be a viable option for corrosive environments. For instance, stainless steel channels possess a high level of resistance to corrosion thanks to their significant chromium content. They can endure exposure to moisture, chemicals, and other corrosive substances without undergoing deterioration. Conversely, carbon steel channels may not be as well-suited for corrosive environments since they are more susceptible to rust and corrosion. In such instances, additional protective measures such as coatings or galvanization might be necessary in order to prevent corrosion. Ultimately, the appropriateness of steel channels for corrosive environments will hinge upon the specific application and the selected type of steel. Therefore, it is crucial to consult experts or engineers to ascertain the optimal material for a given corrosive environment.

- Q: How do steel channels perform in terms of fire resistance?

- Steel channels perform well in terms of fire resistance due to their high melting point and structural integrity. They do not combust or release toxic fumes when exposed to fire, making them a reliable choice for construction in fire-prone areas. Additionally, steel channels can help maintain the integrity of a structure during a fire, providing support and preventing collapse.

- Q: What is the wall thickness of national standard 8* channel steel?

- Should refer to the GB 8 channel height 80 leg width 43 waist thickness 5.Channel steel is a strip of steel with a cross section. Section steel with groove shape.Channel steel is divided into ordinary channel steel and light channel steel. Standard Specification for hot-rolled plain channel steel is 5-40#. Specifications for hot rolled flexible channel steel supplied by supply and demand agreement are 6.5-30#. Channel steel is mainly used for building structures, vehicle manufacturing, other industrial structures and fixed plates, cabinets, etc., and channel steel is often used in conjunction with i-beam.According to the channel shape and can be divided into 4 kinds: cold bending equilateral channels, cold-formed non equilateral channel steel, cold rolled edge channels, the cold bending edge channelsAccording to the theory of steel structure, it should be stressed by the channel plate, that is to say, the channel should stand rather than lie prone.

- Q: Classification, use and material of channel steel

- Channel steel is divided into ordinary channel steel and light channel steel. Standard Specification for hot-rolled plain channel steel is 5-40#. Specifications for hot rolled flexible channel steel supplied by supply and demand agreement are 6.5-30#.

- Q: Are steel channels suitable for agricultural storage buildings?

- Agricultural storage buildings can indeed make use of steel channels. Steel channels, which are also referred to as C-channels or U-channels, are commonly utilized in the construction industry because of their strength and durability. They provide robust structural support and have the ability to handle heavy loads, making them perfect for storing agricultural machinery, equipment, and livestock feed. Moreover, steel channels possess resistance against pests, fire, and rot, which guarantees the safety and longevity of the storage building. They are also highly adaptable and can be easily customized to fulfill specific storage requirements, such as the addition of shelves or hooks for hanging tools and equipment. In summary, steel channels are a dependable option for agricultural storage buildings, offering a solid and secure solution for farmers and agricultural businesses.

- Q: Can steel channels be used in overhead crane systems?

- Certainly! Overhead crane systems can make use of steel channels. Thanks to their structural integrity and strength, steel channels are frequently employed in the construction of these systems. They provide a robust support system for the crane's movement along the rails and can endure the heavy loads typically lifted by overhead cranes. Furthermore, steel channels allow for easy welding or bolting together to achieve the necessary length and configuration for the crane system. In summary, steel channels offer a dependable and economical choice for overhead crane systems.

- Q: What is the difference between steel tubes such as channel steel and square tube?

- The use of square construction, machinery manufacturing, shipbuilding, steel construction projects, solar power support, steel structure engineering, power engineering, power plant, agricultural and chemical machinery, glass curtain wall, car chassis, airport, boiler construction, highway railings, housing construction, pressure vessels, oil tanks, bridges, power station equipment. Cranes and other high load welding etc..

- Q: Can steel channels be used in manufacturing equipment?

- Yes, steel channels can be used in manufacturing equipment. Steel channels, also known as C-channels or U-channels, are popular structural components in various industries due to their strength and versatility. They are commonly used to create frames, supports, and structures for machines and equipment. Steel channels provide stability and rigidity, making them suitable for handling heavy loads and withstanding dynamic forces during the manufacturing process. Additionally, steel channels can be easily welded, bolted, or fastened together, allowing for flexible and efficient construction of equipment. Overall, steel channels are a reliable choice for manufacturing equipment due to their durability, strength, and ease of use.

Send your message to us

Height 88mm the Thickness 18mm Surface and Length: according to the requirements of Channel Steel

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords