Height 83mm the Thickness 8mm Surface and Length: according to the requirements of Channel Steel

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Height 88mm the Thickness 8mm Surface and Length: according to the requirements of Channel Steel

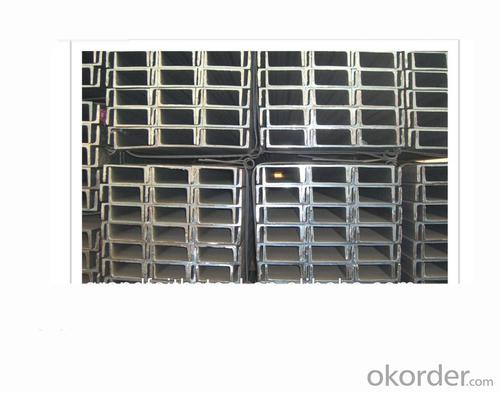

U Channel Steel the Length Thickness According to the Customer

1、the details information of our Channel Steel

1)the ordinary model

Height: | 90-400mm |

Thickness: | 9-14.5mm |

Surface: | according to the customers’ requirements |

Length: | As customers’ requirements |

Size: | 90*37*4.5mm--400*104*14.5 mm . |

Punch: | Can be punched as customer's drawing |

Material: | Q195/Q235/ Q215/Q345/SS400/S235JR, A36,SS400,SS540 ASTM A36 and so on |

2)the light model

Height: | 90-400mm |

Thickness: | 6.4-8.0mm |

Surface: | Painted or Galvanized;according to the customers’ requirements |

Length: | As customers’ requirements |

Size: | 50*32*4.4mm--400*115*8.0mm . |

Punch: | Can be punched as customer's drawing |

Material: | Q195/Q235/ Q215/Q345/SS400/S235JR, A36,SS400,SS540 ASTM A36 and so on |

2、the Product Advantage

1) We can design the channel steel according to customers’requirements

2) We can manufacture under complete quality control system---ISO9001&SGS

3) We can installed with instruction of experienced engineers

4) Easy to assemble and dismantle

5) Eco-friendly material: can be used for several times and can be recycled

6) Shorter construction period, longer using time

7) High strength and stiffness, high weight bearing.

3、why choose us ?Product Advantage

1)The channel steel quality is prime quality

2)Our price is competitive price with our competitor

3)We provide the professional service

4)Prompt delivery & Seaworthy packing

5)Mill Test Certificate

Company Information

which is one of the largest manufacturing bases of Steel Channel in northern China. We are a company that is specialized in producing Stainless Steel Channel、Prime Stainless Steel Channels and so on.

With years of development, our company won the trust and excellent reputation of customers for the quality of our products and sincere service, as well as foreign users of the community.

Please contact me if you are interested in our products and I will try my best to offer you the best goods and service.

- Q: Are steel channels suitable for use in agricultural applications?

- Yes, steel channels are suitable for use in agricultural applications. They are highly durable, strong, and resistant to environmental factors such as weather and pests. Steel channels can be used for various purposes in agriculture, including constructing animal enclosures, framing structures, and supporting equipment. Their versatility and reliability make them a popular choice in the agricultural industry.

- Q: Can steel channels be used for equipment platforms?

- Yes, steel channels can be used for equipment platforms. They provide a strong and durable base for supporting heavy equipment and can be easily customized to fit specific design requirements.

- Q: Can steel channels be used for creating support structures for conveyor systems?

- Yes, steel channels can be used for creating support structures for conveyor systems. Steel channels offer excellent strength and durability, making them suitable for supporting heavy loads and providing stability to conveyor systems. The rigid nature of steel channels ensures that the support structure remains intact and can withstand the constant movement and vibrations associated with conveyor systems. Additionally, steel channels can be easily fabricated to meet specific requirements and can be welded or bolted together to create a customized support structure for the conveyor system. Overall, steel channels are a popular choice for creating support structures for conveyor systems due to their strength, durability, and versatility.

- Q: What are the different methods for designing steel channels for seismic loads?

- There are several methods for designing steel channels for seismic loads. One common approach is to use the direct analysis method, which involves performing a detailed finite element analysis to determine the forces and deformations in the channel under seismic loading. Another method is the equivalent lateral force method, which simplifies the seismic forces into equivalent lateral forces that act on the structure. The response spectrum method is another technique, where the seismic forces are determined based on the response spectrum of the ground motion. Additionally, the capacity design method can be employed, which involves designing the channel to ensure that certain critical elements of the structure fail in a controlled manner before others in order to improve the overall seismic performance. Ultimately, the specific method chosen will depend on various factors such as the complexity of the structure, the desired level of accuracy, and the available resources and expertise.

- Q: What are the different types of hangers used for steel channels?

- There are several different types of hangers used for steel channels, including clevis hangers, u-bolt hangers, pipe hangers, and beam clamps. These hangers are designed to provide support and secure the steel channels in various applications, such as construction, plumbing, and electrical installations. Each type of hanger has its own specific design and mounting method to accommodate different channel sizes and load capacities.

- Q: What does channel C10 mean? What is the full name of C?

- Decent channel steel, with two thicker legs, does not curl (it rolls too tightly). Used for stressed structures.

- Q: What is a steel channel?

- A steel channel, also known as a C-channel or U-channel, is a structural component made of steel that is shaped like a "C" or a "U." It is commonly used in construction and manufacturing industries for various applications. Steel channels are typically made from hot-rolled steel or cold-formed steel, and they come in various sizes and thicknesses to suit different requirements. The shape of a steel channel provides excellent strength and support, making it ideal for structural applications such as framing, bracing, and supporting loads. It is often used to create beams, columns, and purlins in buildings, bridges, and other infrastructures. Steel channels are also used in manufacturing processes where strength and rigidity are essential, such as in the fabrication of machinery, vehicles, and equipment. They can be used as frames, rails, or supports, providing stability and durability to the finished product. Additionally, steel channels can be used for decorative purposes in architectural designs. They can be incorporated into interior or exterior designs to add visual interest, create unique shapes, or provide a modern industrial aesthetic. Overall, a steel channel is a versatile and reliable component that offers strength, support, and flexibility in various construction and manufacturing applications.

- Q: What are the different methods of anti-slip treatment for steel channels?

- When it comes to anti-slip treatment for steel channels, there are various methods available, each with its own advantages and suitability for specific purposes. Some commonly used methods include: 1. Grip tape: This cost-effective solution involves applying adhesive-backed tape with a textured surface onto the steel channel. Grip tape is easy to install and offers good traction, making it ideal for areas with light to moderate foot traffic. 2. Anti-slip coatings: These coatings are specially designed to create a rough surface on the steel channel, enhancing slip resistance. They can be applied using a brush, roller, or spray and are made from materials like epoxy, polyurethane, or acrylic. Anti-slip coatings are durable and able to withstand heavy foot traffic, making them suitable for industrial environments. 3. Perforated plates: These steel plates have small holes punched throughout their surface, allowing liquids to drain through and reducing the risk of slipping. Perforated plates are commonly used in outdoor areas or where liquids are present, such as walkways, platforms, or stair treads. 4. Expanded metal: This type of steel sheet is slit and stretched to create diamond-shaped openings. The raised surface of expanded metal provides excellent anti-slip properties, making it ideal for ramps, stair treads, or catwalks. Additionally, expanded metal is durable and resistant to corrosion, increasing its longevity. 5. Welded serrated grating: This method involves welding serrated bars onto a steel channel, creating a rugged surface that improves traction. Welded serrated grating is commonly used in heavy-duty applications where high slip resistance is necessary, such as oil rigs, power plants, or manufacturing facilities. It is crucial to consider the specific requirements of the steel channel and the intended usage when selecting an anti-slip treatment method. Factors like foot traffic, exposure to liquids, and the need for durability should be taken into account to ensure the chosen method is suitable for the application.

- Q: What are the different types of connections used with steel channels?

- There are several types of connections used with steel channels, including welding, bolting, and using steel channel connectors.

- Q: Can steel channels be used in renewable energy installations?

- Yes, steel channels can be used in renewable energy installations. Steel channels are commonly used in various renewable energy applications, such as solar panel mounting systems and wind turbine support structures. The durability and strength of steel make it an ideal material for withstanding the environmental conditions and load requirements in renewable energy installations. Additionally, steel channels can be easily fabricated and customized to meet the specific needs of different renewable energy projects.

Send your message to us

Height 83mm the Thickness 8mm Surface and Length: according to the requirements of Channel Steel

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords