Height 87mm the Thickness 8mm Surface and Length: according to the requirements of Channel Steel

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

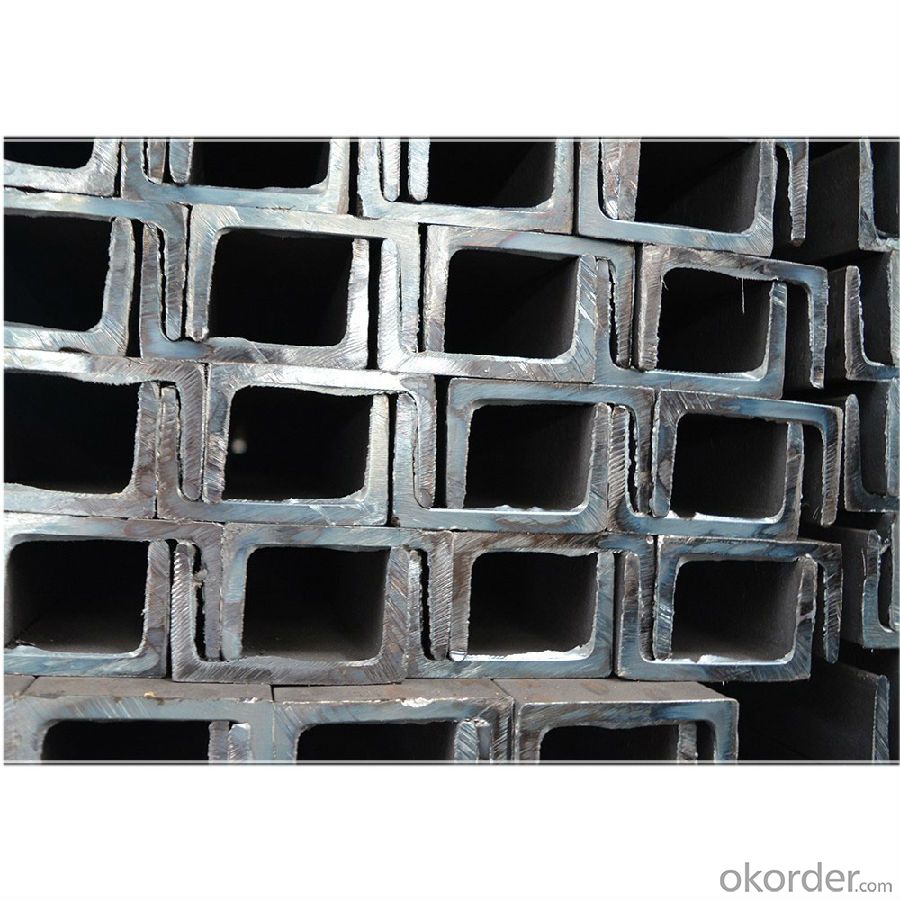

Height 87mm the Thickness 8mm Surface and Length: according to the requirements of Channel Steel

U Channel Steel the Length Thickness According to the Customer

1、the details information of our Channel Steel

1)the ordinary model

Height: | 90-400mm |

Thickness: | 9-14.5mm |

Surface: | according to the customers’ requirements |

Length: | As customers’ requirements |

Size: | 90*37*4.5mm--400*104*14.5 mm . |

Punch: | Can be punched as customer's drawing |

Material: | Q195/Q235/ Q215/Q345/SS400/S235JR, A36,SS400,SS540 ASTM A36 and so on |

2)the light model

Height: | 90-400mm |

Thickness: | 6.4-8.0mm |

Surface: | Painted or Galvanized;according to the customers’ requirements |

Length: | As customers’ requirements |

Size: | 50*32*4.4mm--400*115*8.0mm . |

Punch: | Can be punched as customer's drawing |

Material: | Q195/Q235/ Q215/Q345/SS400/S235JR, A36,SS400,SS540 ASTM A36 and so on |

2、the Product Advantage

1) We can design the channel steel according to customers’requirements

2) We can manufacture under complete quality control system---ISO9001&SGS

3) We can installed with instruction of experienced engineers

4) Easy to assemble and dismantle

5) Eco-friendly material: can be used for several times and can be recycled

6) Shorter construction period, longer using time

7) High strength and stiffness, high weight bearing.

3、why choose us ?Product Advantage

1)The channel steel quality is prime quality

2)Our price is competitive price with our competitor

3)We provide the professional service

4)Prompt delivery & Seaworthy packing

5)Mill Test Certificate

Company Information

which is one of the largest manufacturing bases of Steel Channel in northern China. We are a company that is specialized in producing Stainless Steel Channel、Prime Stainless Steel Channels and so on.

With years of development, our company won the trust and excellent reputation of customers for the quality of our products and sincere service, as well as foreign users of the community.

Please contact me if you are interested in our products and I will try my best to offer you the best goods and service.

- Q: How do steel channels perform under extreme weather conditions?

- Steel channels are known for their excellent performance under extreme weather conditions. The inherent strength and durability of steel make it highly resistant to harsh weather elements such as high winds, heavy rains, extreme temperatures, and even earthquakes. In terms of high winds, steel channels have a high resistance to wind loads due to their rigidity and stability. They are designed to withstand strong gusts without warping or bending, making them ideal for applications in hurricane-prone areas or regions with high wind speeds. When it comes to heavy rains and flooding, steel channels are also highly reliable. They have a superior resistance to water damage and corrosion, which prevents the structural integrity from being compromised. Additionally, steel channels can be coated or galvanized to provide an extra layer of protection against rusting and moisture. Extreme temperatures, whether hot or cold, do not significantly affect the performance of steel channels. Steel has a high melting point, making it resistant to heat and fire. Moreover, it retains its strength and integrity even in extremely low temperatures, ensuring that it does not become brittle or prone to fractures. Finally, steel channels have proven to be resilient in earthquake-prone areas. The inherent ductility of steel allows it to flex and absorb seismic forces, reducing the risk of collapse or structural damage. This is especially crucial in regions with high seismic activity, where the ability of steel channels to withstand ground shaking is of utmost importance. In conclusion, steel channels excel under extreme weather conditions due to their strength, durability, resistance to wind, water, and temperature, as well as their ability to withstand seismic forces. Their reliability makes them a preferred choice for various applications in both residential and commercial construction, ensuring the safety and longevity of structures in challenging weather environments.

- Q: No. 20 I-beam span 3 meters, fixed on both sides, what is the maximum weight to bear? No. 10 channel steel, span 2.5 meters, the other ibid

- I-beam is also called steel girder (English name Universal Beam). It is a strip of steel with an I-shaped section. I-beam is divided into ordinary I-beam and light I-beam, H steel three. It is a section steel whose shape is trough.

- Q: How do steel channels contribute to the energy efficiency of a building?

- Steel channels contribute to the energy efficiency of a building in several ways. Firstly, steel channels can be used to create structural frames and support systems, which help distribute the weight of the building evenly and efficiently. This allows for more open and flexible floor plans, reducing the need for additional support columns and walls. By minimizing the use of materials, steel channels help optimize the use of space and reduce the overall energy consumption required for construction. Additionally, steel channels are known for their high strength-to-weight ratio, which means they can support heavy loads while having a relatively low weight themselves. This property allows for the construction of taller and larger buildings, maximizing the usable space without compromising on structural integrity. As a result, more occupants can be accommodated within a smaller footprint, leading to greater energy efficiency in terms of land use. Steel channels also contribute to energy efficiency through their durability and longevity. Steel is a highly durable material that can withstand extreme weather conditions, resist corrosion, and remain structurally sound over time. This reduces the need for frequent repairs and replacements, resulting in lower maintenance costs and less energy consumption associated with building maintenance. Furthermore, steel channels can be used as part of an efficient insulation system. Insulated steel channels can be integrated into the building envelope, providing a thermal barrier that helps regulate indoor temperature. This insulation reduces the reliance on heating and cooling systems, resulting in lower energy consumption and improved energy efficiency. Lastly, steel channels are often made from recycled steel, which has a significantly lower carbon footprint compared to the production of virgin steel. By using recycled materials, the environmental impact of the building's construction is reduced, contributing to overall energy efficiency. In conclusion, steel channels contribute to the energy efficiency of a building by enabling efficient structural designs, optimizing space utilization, providing durability and longevity, supporting insulation systems, and utilizing recycled materials. These factors collectively reduce energy consumption, improve building performance, and contribute to a more sustainable and environmentally friendly construction industry.

- Q: What are the environmental benefits of using steel channels?

- There are several environmental benefits of using steel channels. Firstly, steel is a highly durable material that can withstand harsh weather conditions and has a long lifespan, reducing the need for frequent replacements. This durability reduces the overall environmental impact associated with manufacturing, transportation, and disposal of construction materials. Additionally, steel is a highly recyclable material, with a recycling rate of over 90%. By using steel channels, we can contribute to reducing the demand for new steel production, conserving natural resources, and minimizing carbon emissions associated with the extraction and manufacturing of raw materials. Lastly, steel is fire-resistant and non-combustible, making it a safer and more sustainable choice compared to other materials.

- Q: How to connect channel steel and round steel?

- Vertical welding of channel steel and round bar axis:First, the channel steel, channel cut, need to connect the length of the arc shaped gap, and then again and round steel arc surface welding, welding before the two kinds of materials to rust, and full welding.

- Q: Can steel channels be used for equipment supports?

- Yes, steel channels can be used for equipment supports. Steel channels are commonly used in construction and industrial applications for their strength and durability. They can provide stable and reliable support for various types of equipment, such as machinery, heavy tools, and other heavy loads. Steel channels are designed to withstand high loads and can be easily fabricated and installed to suit specific support requirements. Additionally, they can be used in combination with other structural elements, such as beams and columns, to create a robust support system. Overall, steel channels offer a reliable solution for equipment supports due to their strength, versatility, and long-lasting performance.

- Q: What are the different types of loads that steel channels can bear?

- Steel channels exhibit versatility as structural components capable of bearing different types of loads. The array of loads they can endure includes: 1. Compression Load: With a high load-bearing capacity, steel channels can effectively withstand compression forces. They find common usage in columns and beams, providing support for the weight of structures and facilitating vertical load transfer. 2. Tension Load: Steel channels possess the capability to resist tension loads, effectively countering forces that aim to pull or stretch the material. This attribute renders them appropriate for applications such as trusses or suspension systems. 3. Shear Load: Steel channels exhibit resilience against shear forces, which arise when two parallel forces exert themselves in opposite directions. They frequently find application in structural systems, effectively counteracting the shearing effects of horizontal loads like wind or seismic forces. 4. Bending Load: Steel channels proficiently bear bending loads, which emerge when forces are applied perpendicularly to the channel's axis. They are often utilized as beams or lintels, providing support for loads positioned over openings like doors or windows. 5. Axial Load: Steel channels are designed specifically to withstand axial loads, which act along the channel's longitudinal axis. These loads can either be compressive or tensile and are typically encountered in columns or vertical members. 6. Lateral Load: Steel channels possess the ability to bear lateral loads, which exert themselves perpendicular to the channel's longitudinal axis. These loads commonly originate from wind, earthquakes, or other horizontal forces and are effectively countered by the structural system incorporating the channel. In conclusion, steel channels offer a versatile option for structural applications due to their capacity to bear various types of loads. Their strength, durability, and flexibility render them suitable for an extensive range of construction and engineering projects.

- Q: What are the typical applications of steel channels?

- Steel channels have various typical applications across multiple industries. They are commonly used in construction projects for framing, supporting structural loads, and creating framework for buildings, bridges, and infrastructure. Steel channels also find applications in manufacturing, where they are utilized as structural components in machinery, equipment, and vehicles. Additionally, they are frequently employed in the production of storage racks, shelving systems, and electrical enclosures. Overall, steel channels are versatile and widely used due to their strength, durability, and ability to provide structural support in a variety of applications.

- Q: Can steel channels be used for roofing applications?

- Steel channels are not commonly utilized for roofing purposes. They are typically employed in construction projects for supporting beams, columns, and framing. Instead, roofing applications typically involve the use of materials like metal panels, asphalt shingles, clay or concrete tiles, or even thatched roofing. These materials are specifically designed and manufactured to ensure weatherproofing, insulation, and durability, providing protection to the structure and its inhabitants against external elements. Although steel channels may have other significant uses in construction, they lack the necessary qualities required for an effective and long-lasting roof, thus rendering them unsuitable for roofing applications.

- Q: What are the different load capacities of steel channels?

- The load capacities of steel channels can vary depending on various factors such as the size and shape of the channel, the type of steel used, and the method of installation. However, steel channels are generally known for their high load-carrying capacity due to the inherent strength of steel as a construction material. The load capacities of steel channels are typically specified by manufacturers and engineers based on extensive testing and calculations. These load capacities are usually expressed in terms of the maximum allowable load that the channel can safely support without experiencing structural failure or deformation. To determine the load capacity of a specific steel channel, it is important to consider the relevant design codes and standards, which provide guidelines for calculating load capacities based on factors such as material properties, design factors of safety, and anticipated loads. It is also worth noting that load capacities can differ between different types of steel channels, such as C-channels, U-channels, and various custom shapes. Additionally, load capacities can be influenced by other factors such as the length and span of the channel, the type and placement of fasteners, and the overall structural design. Ultimately, it is crucial to consult with manufacturers, structural engineers, or reference design codes to determine the specific load capacities of steel channels for a given application.

Send your message to us

Height 87mm the Thickness 8mm Surface and Length: according to the requirements of Channel Steel

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords