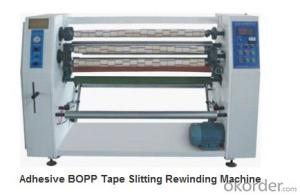

HCHS2002A Saeries BOPP Tape Slitter Rewinding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 15 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of HCHS2002A Saeries BOPP Tape Slitter Rewinding Machine

1. The slitter rewinder machine is suitable for slitting BOPP packaging & stationery tapes.

2. 4 shafts automatic exchange..

Application of HCHS2002A Saeries BOPP Tape Slitter Rewinding Machine

the Bopp adhesive tape slitter rewinder machine is 4 shafts auto turret exchange, suitable for slitting rewinding BOPP packaging & stationery tapes.

Specification of HCHS2002A Saeries BOPP Tape Slitter Rewinding Machine

Max. working widths: 1.3m, 1.6m Jumb-roll unwind diameter: 750mm

Mini. slitting width: 12mm up (optional) Slitting blade: razor blade (0.2x22x60mm)

Rewind paper core: 3" (76.2mm) Max. rewind diameter: 150mm (4 shafts exchange)

Feature of HCHS2002A Saeries BOPP Tape Slitter Rewinding Machine

1. Equipped with connected unwind base, which is convenience on operationand space saving.

2. Equipped with surface type lay on roller on unwind base to make web wound out more smoothly.

3. Slitting by razor blade, which was designed to slit various film tapes.

4. Driven by one A.C motor with 3 stages type length counter to make machine stops accurately.

5. Rewind tension is controlled by clutch, it works with differential shafts to make tension on each roll the same even when the web thickness is not the same at all.

6. Finished rolls unload and paper cores reload working by core loader (HCSA105), it increases full production capacity.

Optional Part of HCHS2002A Saeries BOPP Tape Slitter Rewinding Machine

1. Core Alum. mold: it is needed when slitting different sizes, any sizes can be made on your request.

2. Unwind base: connected shaft type, jumbo-roll uplifting.

3. Auto tabber: label tape roll unwind system.

4. Slitter blade: air scroll knife (width 10mm) with firm roller and guide bar.

5. Noise reduction hood: connected unwind safety cover, hydraulic control.

- Q: Where is secondhand corrugated paper packaging machinery available?

- And in the packaging materials, carton packaging accounted for a large part of the weight.Therefore, the carton factory is still very optimistic about the prospects.Business is best to have their own, if not, it is like playing a battle without vigor.But if you have better personal skills, you can also sell it to someone else's factory.After all, it is impossible to have friends and relatives need cartons, no "relationship" can be bigger and stronger.

- Q: Bread packing machine Product features

- Bread packing machine, also commonly known as pillow type packaging machine. Among them, the suitable packing bread model has CM-320 pillow type packing machine, CM-400 pillow type bread packing machine

- Q: What is the price of a small jujube packing machine?

- Small packaging machine is mainly divided into single grain and multi grain packaging, there are 3-6, there are about 200000. Mainly depends on the performance and use of the machine

- Q: What are the packing machines?

- Glass glue category of automatic and manual soft packing machine, chemical, I do not know what you are talking about? You can go and have a look.

- Q: What machine does the packing carton machine have?

- Since its establishment, the company has continued to provide specialized packaging equipment and transportation equipment for domestic first-class enterprises, as well as perfect solutions for automated transportation systems.

- Q: Working principle of packing machine

- The working principle of the packing machine is simple. The packing material is first installed on the packing machine and installed

- Q: What is the name of the paper used in packing machine parts and yellow?

- Vapor phase rust proof paper is coated with vapor phase corrosion inhibitor on the base of antirust base paper (surface like kraft paper, but with chloride ion and sulfate ion limit requirement)

- Q: How much is the tableware wrapping machine?What's the price of the tableware wrapping machine?

- Tableware packaging machine machine standard price of about 38000, excluding tax, tableware packaging machine is designed for tableware (e.g., chopsticks, bowls, dishes and so on) a modern packaging machinery packaging, this machine is mainly composed of conveyor, packaging machine, output machine, shrink machine, composed of four parts.

- Q: How is the production and characteristics of ceramic wall tiles different from the size and performance of molding?

- Ceramic wall and floor tile is a special term used in building ceramics industry. It refers to the ceramic tile used for paving internal walls, exterior walls and floors.It includes:Glazed tiles: white glazed tile, colored shaddock tile, embossed glazed tile, mottled glazed tile, patterned glazed tile, mural glazed tile.Floor tile: paving brick, red floor tile, ceramic mosaic tile (ceramic mosaic), ladder brick.The exterior wall tiles, glazed tiles, glazed tiles, imitation brick, brick from #.

- Q: Calendering, extrusion, blow molding, pressing, plastic (vacuum forming) and what is the rotational molding

- Plastic forming and processing methodPlastic molding is an engineering technology, involves the plastic into all kinds of plastic products in the process. The transformation process tends to happen in one or more of the following conditions, such as polymer rheology and physical and chemical properties of the change.

1. Manufacturer Overview

| Location | Suzhou, China (Mainland) |

| Year Established | 2006 |

| Annual Output Value | |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe; Central America; Northern Europe; Southern Europe; South Asia |

| Company Certifications | Certificate of Compliance |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 1-2 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 1,000-3,000 square meters |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

HCHS2002A Saeries BOPP Tape Slitter Rewinding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 15 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords