Alfa Aesar Graphite Powder for Refractory Brick, Casting Coating -180, -280, -285, +895, -195

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 111 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

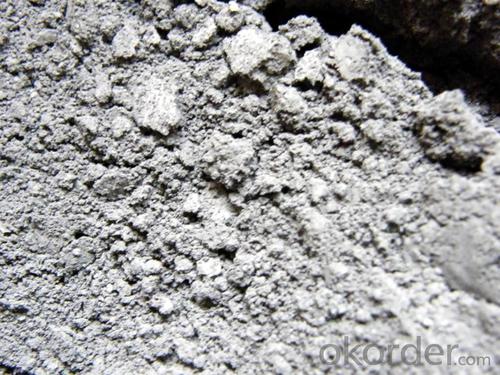

graphite powder manufacturer,with graphite mine.

-180,-280,-285,+895,-195......

30000Mt per year

graphite powder

Particle size: 32mesh to 5000mesh,

carbon content: 80-99.99%.

Property:

Scale is thin,flexible and crystallized completely with excellent physical and chemical properties such as good temperature resistance,self-lubrication,conductibility,heat resistance,shake resistance,and erosion resistance.

Use:

Widely applied to high quality fire resistance material and coating of metallurgy industry,hot working material stabilizer of military industry,lead of light industry,carbon brush of electrical industry,electrode of battery industry,and catalyzer and additive of fertilizer industry.After further process,scale graphite can be made into the following high-tech products such as graphite colloidal graphite,graphite compacting material and composite material,graphite products,and graphite anti-friction additive,which are becoming important nonmetal mineral materials in every industry.

- Q: How to identify iron powder and graphite powder in a simple way?

- Can also take the first touch, using magnets to attract or drop method with acid identification of three substances. [a] analytical method (first touch after magnet): touch the two kinds of powder by hand, are oily powder graphite powder, and then take the other two kinds of powder with a magnet, the magnet can be as for iron, can not be sucked up into powder;

- Q: Use of carburizing agents

- The particle size is too fine, easy to burn, too coarse, float on the surface of liquid steel after adding, and it is not easy to be absorbed by steel. The particle size of 0.2-6mm in the induction furnace, the steel and other ferrous metal particles in 1.4-9.5mm high carbon steel, low nitrogen, particle size in 0.5-5mm, and according to the specific needs of the furnace smelting specific types of workpiece so the details of specific judgment and selection.

- Q: What does composite graphite mean?

- Flexible graphite is prepared into graphite powder as a kind of simple, while the composite graphite is graphite powder with one or more other medium mixed products, their preparation materials are different, the application is different, the above information is a reference to Qingdao Huatai graphite.

- Q: How to deal with graphite powder? Anyone recycle it?

- We have a lot of graphite, and now we have it

- Q: Why is there a range of electrode powder powder resistivity? The reasons for the high and low are not good.

- Read millivolt values and sample height, calculated according to the formula P =UA/IL type resistivity. The resistivity of the conductor is in P, Omega - M; L for voltage measurement distance between two probes for m; A for the conductor cross-sectional area, m2; U, the voltage between two probes for the determination of voltage V; I the strength of the current flowing through the conductors, the resistivity of A. graphite is (8 ~ 13) * 10-6 (/m), high - low note inside magazines. For reference only!

- Q: What mask should be used to prevent stone powder?

- If long-term without protection is inhaled into the lungs, will lead to a lot of precipitation in the lung, which may induce pneumoconiosis (silicosis disease only); in addition, graphite powder is also easy to stimulate the throat and bronchial, cause allergic reactions (asthma). If proper dust control measures are taken, this kind of disease can be avoided.

- Q: What binder does the graphite powder form with?

- Graphite powder is divided into natural graphite powder and artificial graphite powder, graphite powder made of graphite products, you need to add binders, binders useful for a variety of resins, asphalt and so on. 100~200 C is not called high temperature for the preparation of carbon graphite products, but only resin can be prepared at this temperature.

- Q: Crystal graphite of graphite powder

- Pure graphite flake graphite and high directional pyrolytic graphite, which have less defects and larger sizes, can generally be considered as perfect graphite single crystals. Considerable research has been done on the thermal conductivity of such graphite. Under compressive stress, the pyrolytic graphite above 3000K processing, the bulk density is 2.25g/cm, 2.266g/cm is close to the theoretical density of the single crystal, the half width of the diffraction peak (002) show only 0.4 degree angle (mosaic angle), is also very close to the theoretical value of zero. The thermal conductivity of this graphite is shown in table 1. These values are generally considered to represent the corresponding values for single crystal graphite. The thermal conductivity along two principal directions is denoted as lambda a along the layer, and is marked by lambda C along the vertical plane.

- Q: What is the simple test method for graphite powder used in casting?

- Mainly depends on its carbon content, hand stick a little bit on the white paper uniform, if there is a clear scratch is graphite powder

- Q: What is graphite powder?

- Graphite is a crystalline mineral of carbonaceous elements. Its crystalline framework is hexagonal layered structure. The distance between each network layer is 340pm, and the distance between the carbon atoms in the same network layer is 142pm;. Of the six Fang system with a complete lamellar cleavage. The cleavage surface is mainly based on molecular bonds, and has weaker molecular attraction, so its natural floatability is very good.Graphite and diamond, carbon 60, carbon nanotubes are carbon elements, they are allotropes.

Send your message to us

Alfa Aesar Graphite Powder for Refractory Brick, Casting Coating -180, -280, -285, +895, -195

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 111 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches