Good Quality PU Sandwich Panels - Corrugated EPS Sandwich Panel for Prefab Building

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | corrugated EPS sandwich panel 1. Naked packing in 20' or 40' container 2. Steel pallet with belt in 40' container |

| Delivery Detail: | 15-20 days after receipt of down payment for wall panel |

Specifications

corrugated EPS sandwich panel

1)sound & hot insulation

2)fire&water proof

3)thickness: 25-100mm

4)USD13-28/m2

Packaging & Delivery

| Packaging Detail: | corrugated EPS sandwich panel 1. Naked packing in 20' or 40' container 2. Steel pallet with belt in 40' container |

| Delivery Detail: | 15-20 days after receipt of down payment for wall panel |

Specifications

corrugated EPS sandwich panel

1)sound & hot insulation

2)fire&water proof

3)thickness: 25-100mm

4)USD13-28/m2

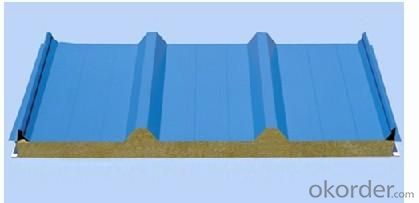

Corrugated EPS sandwich panel for prefab building

Product Description

Corrugated EPS sandwich panel is composed of two layers of pre painted steel sheets with the hard forms of polyurethane as core, which features fireproof materials. It is suitable for the various roofs and walls referring to the large-size factory buildings, storages, exhibition halls, gymnasiums, freezing stores, purification workshops etc, which features temperature-keeping, heat insulation, weight-bearing, weatherproof with the rich color and good appearance.

Specification: | |

Surface Texture and Appearance | Small wave, Flat, Big rib |

Thickness of steel plate | 0.35-0.6mm |

Heat Insulating Material | EPS(polystyrene) |

Thermal conductivity | 0.044w/m.k |

Unit Weight of Core Material | 7-20KG/m3 |

Thickness of Core Material | 40mm, 50mm, 75mm, 100mm,(min thickness for roof: 30mm) |

Effect Width | 950mm, 1150mm |

Color | White grey, Sliver, Sea Blue, Red, etc |

Recommended Coating | PE, PVDF, HDP |

Recommended Plating | Hot-dip galvanized, Al-Zn coated |

Features | 1.Fire resistant; 2.Heat Insulating; 3.Light Weight |

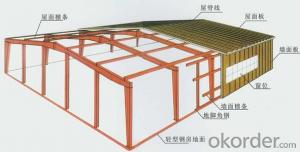

Corrugated EPS sandwich panel application

* Steel structure warehouse

* Temporary office & accommodation

* Commercial prefab building for poultry

Packaging & Shipping

In order to save the space & load the max quantity, it is normally without packing. But steel plate pallet packing for corrugated EPS sandwich panel is also workable.

- Q: Polyurethane sandwich panels in the polyurethane is what material, what are the benefits of industrial building materials should choose polyurethane?

- It should be, for example, naphthalene anthracene, and several rings are capable of forming a closed conjugate system. Generally speaking, more than four benzene rings are fused (for example, 1.2-benzo, 3-methyl Anthracene, etc.) are mostly carcinogenic substances, which are mostly anthracene derivatives, the relationship between the mechanism of carcinogenesis and structure is not yet fully understood ...

- Q: 3 side of the wall surrounded by color steel ~ the other side of the water ~ Will the three sides of the gap with the wall how to waterproof ~ Question added: whether you can use the blowing agent, the top of the same thing (which tell me what) And then sealed with black glue. More

- On the basis of absorbing and studying the employee 's crisis consciousness and improving the desire, they summarize the ten ideas of self - improvement

- Q: Similar to the color steel tile, floor board, the roof of the push is how much ah

- (Polyurethane waterproof coating, asphalt, etc.); small gap, you can directly hit the silicone sealant; the same time, you can use the silicone sealant, Above all have to ensure that color steel plate fixed firmly, or if loose will damage the water

- Q: General color steel foam sandwich panels. How much a square is flat

- but generally do not choose the best

- Q: Will the use of color steel sandwich panels ceiling package package how much money a square? M14 round steel to do hanging bars, 950 sandwich panels, the main bone 160 * 60 * 20 * 2.5 C steel Is the workshop ceiling, I should quote how much appropriate,

- What are the sub-items of the general project that should be prepared for the special safety program? What should be included in the special programming? The following dangerous parts of the sub-sub-projects and temporary electricity equipment in 5 and above or the total capacity of equipment in the 50kW and above the construction site of temporary electricity construction

- Q: 02J611-4 aluminum alloy color steel stainless steel sandwich panel door Atlas who made a thank you

- You can find the relevant property management patiently about the exchange, from the professional point of view, it is recommended that you choose the East Rainbow waterproof products and standardized construction team, the East Rainbow is the best quality waterproof listed enterprises RPUF-371 spray Dust polyurethane waterproof and thermal insulation integration system "Rainbow" spray foam polyurethane foam waterproof insulation integrated system is a rigid foam polyurethane foam waterproof insulation integrated material and the protection of the surface layer composition

- Q: Can sandwich panels be used for ticket booths?

- Yes, sandwich panels can be used for ticket booths. Sandwich panels are versatile and commonly used in construction due to their lightweight, durable, and insulating properties. They can be easily customized to meet specific requirements, making them suitable for ticket booths that need to be portable, weather-resistant, and secure. Additionally, sandwich panels offer good thermal and acoustic insulation, ensuring a comfortable environment for booth attendants and customers.

- Q: What is the difference between rock wool sandwich panels, EPS sandwich panels and polyurethane sandwich panels?

- With the construction specifications quickly calculated to you, you can call me, I am a professional to do this full of construction team

- Q: 50mm thickness of color steel foam sandwich board how much money a flat

- The heat dissipation part of the rosewood boiler is made up of pure aluminum radiator and axial fan

- Q: The stove is dedicated to the plastic used for plastic paper

- Before you understand this specification, you must first understand what is the tripod

Send your message to us

Good Quality PU Sandwich Panels - Corrugated EPS Sandwich Panel for Prefab Building

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords