Geotextile Blanc Polypropylene Staple Fiber Geotextile, High Tensile Strength

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Brief Introduction of Polypropylene Staple Fiber Geotextile

Material:Polypropylene

Weight:100~800g

Width:1~6m

Length:30~100m;or as your request

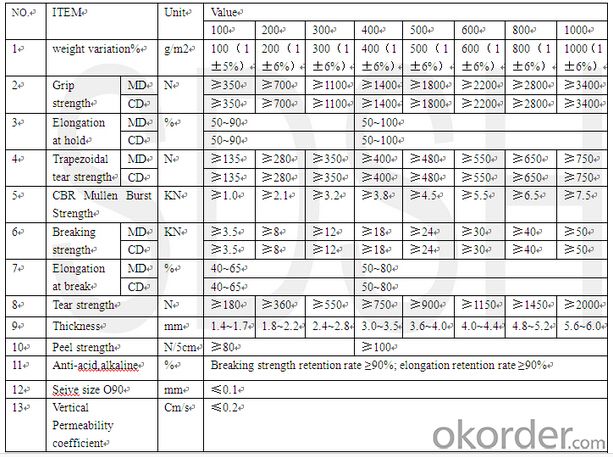

2,Feature of Polypropylene Staple Fiber Geotextile

Good flexibility,permeability,filtration,separation and easy for construction,acid-proof, alkali-proof, sun-proof, mildew-proof and worm-proof. excellent water permeability, high tensile strength and shock strength, non-toxic and harmless.

3,Package of Polypropylene Staple Fiber Geotextile

Packed in rolls or as per your request

4,Application of Polypropylene Staple Fiber Geotextile

Used in the area of highway, airport, railway,dam, reclamation for filtration, separation drainage and protection. Our product can be used to keep soil from losing, collapsing, shocking and stable the base. Because of good wind resistant and frost resistant, the geotextile can also be used as protection of trees in winter.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

1>How about your company?

A manufacturer & supplier focuses on the production of geo textile and geo bag etc. We have exported this product to Amereica, Europe and South East Asia. Customized product is also available based on your detailed requirements.

2> What's the MOQ ?

We kindly recommend 1x40'HQ as the price would be economical based on large loading quantity.

3>How long can we receive the product after purchase?

It takes about 1 to 2 weeks to finish the production based on the specific production schedual. Then it will depend on the shipping time from loading port to the destination port.

- Q: Are geotextiles suitable for use in underground drainage systems?

- Yes, geotextiles are suitable for use in underground drainage systems. They are commonly used to separate soil layers, filter out fine particles, and provide reinforcement to the drainage system. Geotextiles can enhance the performance and longevity of underground drainage systems by preventing clogging, promoting water flow, and reducing soil erosion.

- Q: Are high geotextiles harmful to people?

- High-tech geotextile is not harmful to people. High-iron geotextile for strong, tensile, anti-friction coefficient, anti-oxidation time and other indicators are very strict, it can be said that geotextile applications so far the highest requirements. The raw materials for the production of geotextile are polypropylene fiber, polypropylene fiber civilian use: can be pure or wool, cotton or viscose blended mixed woven to produce a variety of clothing. Can be used for weaving all kinds of knitwear such as socks, gloves, sweaters, knitted pants, dish cloth, mosquito cloth, was expo, warm filler, diaper wet. Industrial use: geotextile, industrial filter cloth, carpet, fishing nets, canvas, hose, concrete reinforced materials, industrial fabrics, nonwovens and so on. So do not worry, high-speed rail geotextile with environmental requirements, no harm to the human body.

- Q: 300 grams of geotextile how much money a square meter

- See the requirements of the data indicators in general about 2.4 Huazhi geotextile material manufacturers

- Q: Can geotextiles be used in coastal protection?

- Yes, geotextiles can be used in coastal protection. Geotextiles are often employed as a part of coastal erosion control measures to stabilize sandy or loose soils. They can be used to create barriers that prevent erosion by filtering out sediment and allowing water to drain, while also providing reinforcement to the soil and preventing it from being washed away by waves and currents.

- Q: How do geotextiles help with load support in unpaved roads?

- Geotextiles provide load support in unpaved roads by distributing the load from vehicles more evenly across the road surface, preventing the formation of ruts and reducing the amount of settlement. They also help in stabilizing the subgrade by acting as a separation layer between the subgrade soil and the overlying base material, preventing the mixing and migration of fine particles. Additionally, geotextiles improve the overall strength and stability of the road by enhancing its resistance to deformation and improving its load-carrying capacity.

- Q: How do geotextiles affect soil permeability?

- Geotextiles can improve or reduce soil permeability depending on the specific application and design. In some cases, geotextiles act as a filter, allowing water to pass through while trapping fine particles and preventing clogging. This can enhance soil permeability by preventing the formation of a dense layer that obstructs water flow. On the other hand, certain geotextiles can be designed to decrease soil permeability by acting as a barrier, preventing water from infiltrating or draining through the soil. Ultimately, the impact of geotextiles on soil permeability is determined by their purpose and the specific properties of the material used.

- Q: What are the different factors to consider for geotextile selection in mining applications?

- When selecting geotextiles for mining applications, several factors need to be considered. These include the required strength and durability of the geotextile to withstand the specific mining conditions, such as heavy loads, abrasion, and chemical exposure. The geotextile's filtration and drainage properties are also crucial in managing water flow and preventing soil erosion. Additionally, the geotextile's ability to resist biological degradation and UV radiation should be evaluated to ensure long-term performance. Lastly, cost-effectiveness and compliance with environmental regulations should be taken into account during geotextile selection for mining applications.

- Q: Geotextile how much money

- Good point of about 7000 a ton, different quality is not the same price.

- Q: What are the maintenance requirements for geotextiles?

- Geotextiles generally have low maintenance requirements. However, regular inspection and cleaning are important to ensure their optimal performance. The specific maintenance needs may vary depending on the type and application of the geotextile, but in general, it is recommended to remove any debris, sediment, or vegetation that may accumulate on the surface. Additionally, periodic checks for any signs of damage or wear, such as tears or fraying, should be conducted and repairs or replacements should be made as necessary.

- Q: What are the factors to consider when selecting geotextiles?

- When selecting geotextiles, some important factors to consider include the type of project or application, the required strength and durability, the desired permeability and filtration properties, the site conditions such as soil type and slope, the installation and maintenance requirements, as well as cost-effectiveness.

Send your message to us

Geotextile Blanc Polypropylene Staple Fiber Geotextile, High Tensile Strength

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords