Geotextil Para Drenaje Eco-friendly Antislip Non-toxic Home Textile Nonwoven

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 g/m²

- Supply Capability:

- 10000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | roll, fold |

| Delivery Detail: | within 15 days |

Specifications

PP Polyester woven geotextile,filtration,separation,reinforcement,erosion control

PP Polyester woven geotextile, and we sew woven geotextile into geotube,geobag, large area(panel) geotextile.

Geobag/tube:

specification: rectangle shape 4MX6M, cylinder diameter can be 3/4/5M, length to 30m, cubic shape .per your instructions.

Sewn from high tensile woven geotextile.

Woven Geotextile

Material:PP, PET

Color: white,other colors available

Width:1.06-3.7M

Weight: PP 200gsm-1400gsm,Polyester 90gsm-1500gsm

Tensile strength: PP 40KN/M-400KN/M,Polyester<500KN/M permeability:KX10-2-10-5 cm/s, K=1.0-9.9

Pore size: 0.07-0.5mm

Elongation: PP<35%, Polyester<15%< div="">

interweave method:plain, twill etc.

Benefits:filtration,separation,reinforcement,erosion control

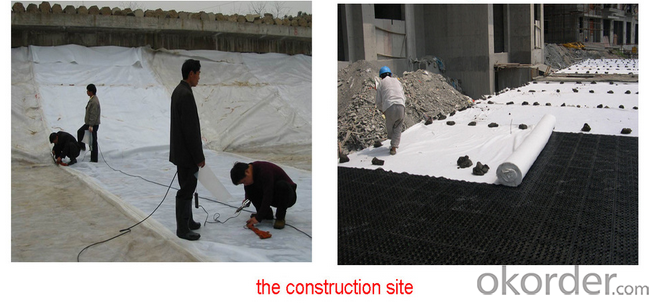

Civil and environmental applications including highways, port facilities, reservoir, transport construction, waste and chemical management, subgrade engineering, coastal protection works, peninsula shoal engineering, subsurface drainage ,pile jacketing etc..

FAQ:

♦ Payment terms: by T/T or L/C |

♦ MOQ:2000 SQM |

♦ If you are interested in our products ,pls advice me the technical index,product weight etc,the more information the better..... |

- Q: What are the considerations for geotextile selection in road rehabilitation projects?

- There are several considerations for geotextile selection in road rehabilitation projects. Firstly, the geotextile should have the appropriate tensile strength to withstand the anticipated loads and stresses in the road structure. Additionally, it should have the proper permeability to allow for effective drainage and prevent water accumulation. The geotextile should also be resistant to chemical degradation and have good durability to ensure a long service life. Finally, factors such as cost, availability, and ease of installation should also be taken into account when selecting a geotextile for road rehabilitation projects.

- Q: What are the standards and regulations for geotextile products?

- The standards and regulations for geotextile products are set by various organizations such as the American Society for Testing and Materials (ASTM), the International Organization for Standardization (ISO), and the Geosynthetic Institute (GSI). These standards cover different aspects of geotextile products, including their physical properties, mechanical performance, durability, and installation guidelines. Compliance with these standards ensures that geotextile products meet the necessary requirements for their intended applications and ensure the safety and reliability of their use in civil engineering and environmental projects.

- Q: What are the quality control measures for geotextile manufacturing?

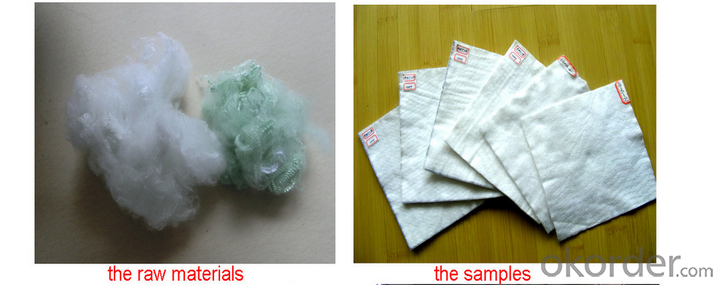

- Quality control measures for geotextile manufacturing typically include the following steps: 1. Raw material inspection: Thoroughly assessing the quality, specifications, and properties of the raw materials used in geotextile manufacturing, such as fibers and polymers. 2. Process control: Implementing strict control over various manufacturing processes, including extrusion, weaving or non-woven production, and coating, to ensure consistency, accuracy, and adherence to specifications. 3. In-line testing: Conducting regular tests and inspections during the manufacturing process to monitor key parameters such as weight, thickness, tensile strength, porosity, and permeability. 4. Sample testing: Randomly selecting samples from each batch and subjecting them to comprehensive laboratory tests to verify compliance with industry standards and project requirements. 5. Quality audits: Conducting periodic audits of the manufacturing facility to assess the overall quality management system, equipment calibration, personnel training, and adherence to standard operating procedures. 6. Final product inspection: Thoroughly examining finished geotextile rolls or panels for any defects, such as tears, holes, or inconsistencies in physical properties, before packaging and shipping. 7. Documentation and traceability: Maintaining detailed records of all quality control activities, including test results, inspection reports, and batch numbers, to ensure traceability and facilitate recalls if necessary. By implementing these quality control measures, geotextile manufacturers can consistently produce high-quality products that meet the performance requirements and specifications of various geotechnical applications.

- Q: Is there a geotextile between the waterproofing membrane and the rigid layer?

- Need to prevent the waterproof layer from being pierced. Huazhi geotextile material manufacturers

- Q: How are geotextiles made?

- Geotextiles are made by weaving or knitting synthetic fibers together to form a fabric that is durable, permeable, and resistant to various environmental conditions. These fibers are typically made of materials such as polyester or polypropylene, which undergo a manufacturing process that includes extrusion, spinning, and heat treatment. The resulting fabric is then often coated or laminated to enhance its performance and functionality in various applications, such as soil stabilization, erosion control, and drainage systems.

- Q: How do geotextiles affect soil properties?

- Geotextiles can significantly impact soil properties by improving stability, erosion control, filtration, and drainage. They act as a barrier to prevent soil erosion and retain soil particles, enhancing the stability of slopes and embankments. Geotextiles also enhance filtration by allowing water to pass through while retaining sediments, which improves water quality. Additionally, they enhance drainage by facilitating the flow of water through the soil, preventing waterlogging and maintaining optimal soil moisture levels. Overall, geotextiles play a crucial role in improving soil properties and protecting against erosion and other soil-related issues.

- Q: How do geotextiles help with ground reinforcement?

- Geotextiles help with ground reinforcement by providing a stable and durable layer that helps distribute load, reduce soil erosion, and improve soil stability. They prevent the mixing of different soil layers, improve drainage, and enhance the overall strength and integrity of the ground.

- Q: Geotextile standard is broken how low?

- Geotextile of the top of the strong implementation of the national standard GB / T-2008, the standard of the geotextile bursting strength requirements in the international arena is not very low. Geotextile because it is produced by fiber acupuncture, and its breaking strength and elongation at break for the main performance indicators, even in practical applications when we are mainly using these two characteristics of geotextile. Breaking strength is called CBR bursting strength, the main test is the product of anti-puncture, the general waterproof, impermeable material requirements are higher, and geotextile is the filter, the protection of materials, so the standard requirements are lower.

- Q: How do geotextiles help with soil reinforcement in soft ground conditions?

- Geotextiles help with soil reinforcement in soft ground conditions by providing a stable and strong layer that distributes the load more evenly. They act as a barrier and prevent the intermixing of different soil layers, improving the overall stability and strength of the ground. Additionally, geotextiles can help with drainage by allowing water to pass through while retaining the soil particles, preventing erosion and maintaining the integrity of the ground.

- Q: How do geotextiles help in reducing the impact of heavy rainfall on soil?

- Geotextiles help in reducing the impact of heavy rainfall on soil by acting as a protective barrier. They allow water to pass through while preventing soil erosion and retaining soil particles in place. This prevents the loss of valuable topsoil, which helps to maintain soil fertility and structure. Additionally, geotextiles aid in promoting water infiltration and drainage, reducing the risk of waterlogging and surface runoff, which can cause floods or soil erosion.

Send your message to us

Geotextil Para Drenaje Eco-friendly Antislip Non-toxic Home Textile Nonwoven

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 g/m²

- Supply Capability:

- 10000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords